A battery remote preheating system, operation method and vehicle of a pure electric vehicle

A pure electric vehicle, battery heating technology, applied in electric vehicle charging technology, electric vehicles, vehicle components and other directions, can solve the problems of remote control, complex preheating function structure, etc., to solve the problem of long battery cold start time, change The effect of low workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

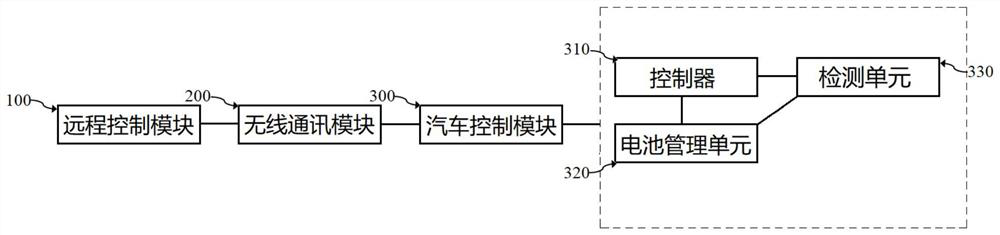

[0038] Refer to attached figure 1 , a remote preheating system for a pure electric vehicle battery in this embodiment, comprising

[0039] The remote control module 100 is used for remotely controlling the work of the vehicle;

[0040] The wireless communication module 200 is used to send the remote preheating instruction of the remote control module 100;

[0041] The vehicle control module 300 is used to control the working state of the vehicle;

[0042] The remote control module 100 sends a control command through the wireless communication module 200 to control the vehicle control module 300 to preheat.

[0043] Use a simple and feasible flow chart to control the realization of the remote preheating function of the battery of pure electric vehicles, avoid changing the hardware structure of the original vehicle's control unit BMS, PDU, and VCU, and add a T-BOX terminal to realize the interaction with the intelligent network platform communication Function, the modificatio...

Embodiment 2

[0060] An operation method for a remote battery preheating system of a pure electric vehicle. The remote control module 100 sends a control command through the wireless communication module 200 to control the vehicle control module 300 to perform preheating. The controller 310 of the vehicle control module 300 receives the wireless communication module 200 The remote preheating command is distributed to the battery management unit 320 and the detection unit 330. After receiving the remote preheating command from the controller 310, the detection unit 330 detects the battery status to determine whether there is a heating demand and feeds back data to the The controller 310, when preheating is required, the controller 310 sends a preheating instruction to the battery management unit 320, and the battery management unit 320 controls and drives the total negative contactor, the battery heating positive contactor, and the battery heating negative contactor to work for preheating ; W...

Embodiment 3

[0063] A vehicle with a remote battery preheating system for pure electric vehicles includes the remote battery preheating system for pure electric vehicles described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com