Rapid material conveying device based on industrial production

A technology for fast transportation and materials, applied in the direction of transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve the problems of reducing the safety of transportation devices, reducing the stability of transportation plates, and plate falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

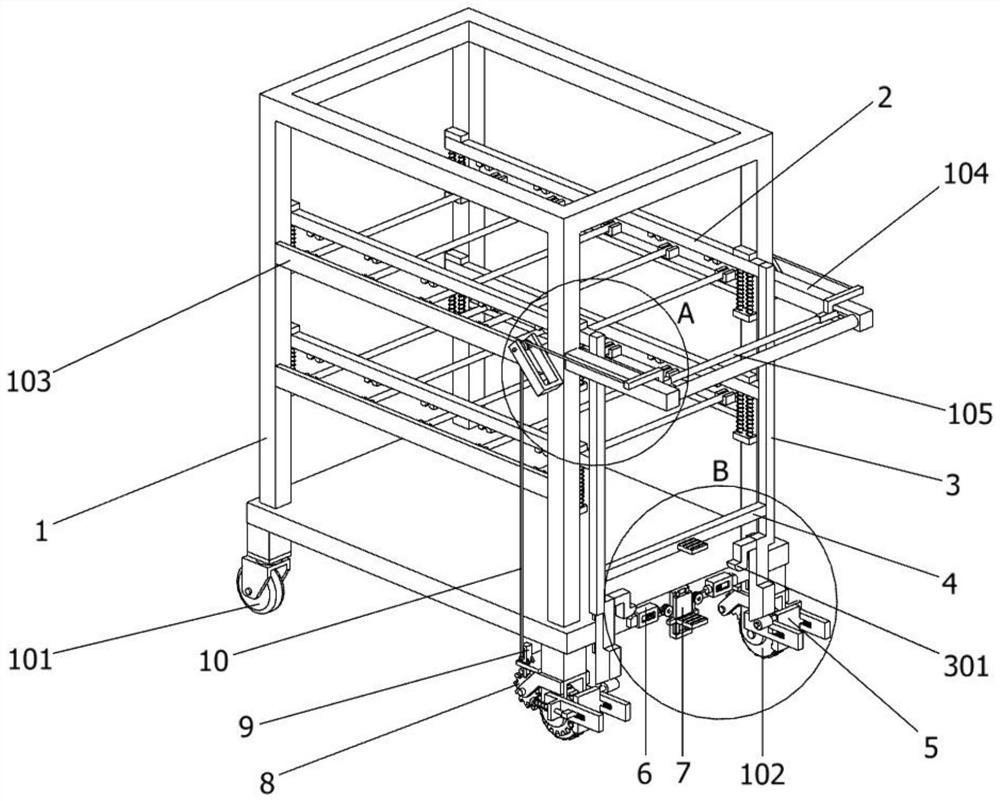

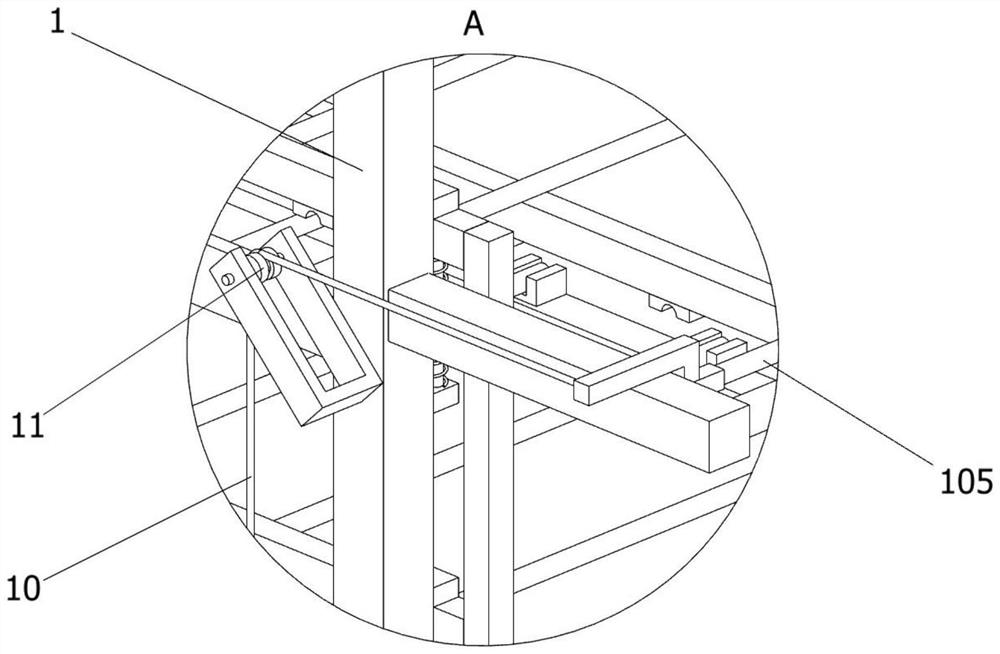

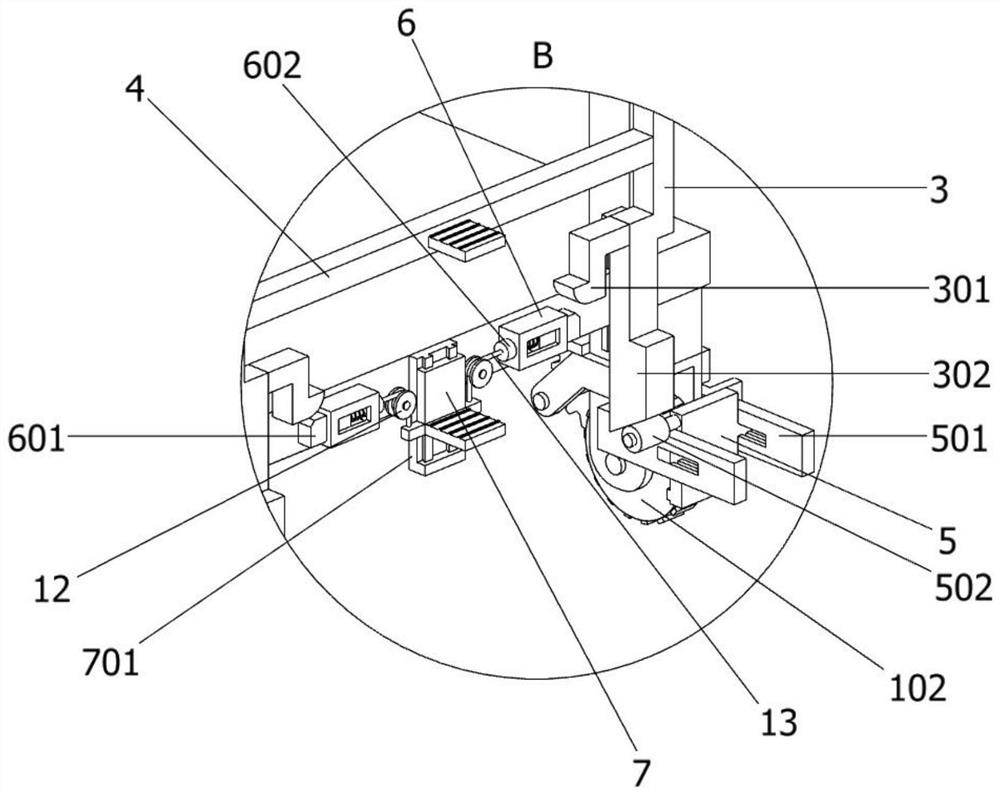

[0036] as attached figure 1 to attach Figure 12 Shown:

[0037] The present invention provides a material rapid transport device based on industrial production, which includes: a vehicle frame 1, four fastening mechanisms 2 are arranged on the inner side of the vehicle frame 1 in front and rear symmetry, and the fastening mechanism 2 includes a limit slide bar 201 and an elastic The pressing part 202, the fastening mechanism 2 is a rectangular rod structure, and the two ends of the fastening mechanism 2 are slidably connected with two limit slide bars 201, and each two adjacent limit slide bars 201 are fixedly connected to the vehicle through a support block. The inner side of the frame 1, and the outside of each limit slide bar 201 is sleeved with a spring, and the bottom end surface of the fastening mechanism 2 is uniformly provided with five elastic pressing pieces 202, and each elastic pressing piece 202 is provided with an arc at the bottom end surface. shaped groove, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com