Pipeline dredging vehicle with adjustable threaded wheels

A technology of threaded wheels and dredging vehicles, which is applied in waterway systems, water supply installations, buildings, etc., can solve the problems of ineffective pipelines, weak obstacle avoidance ability, and insufficient traction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

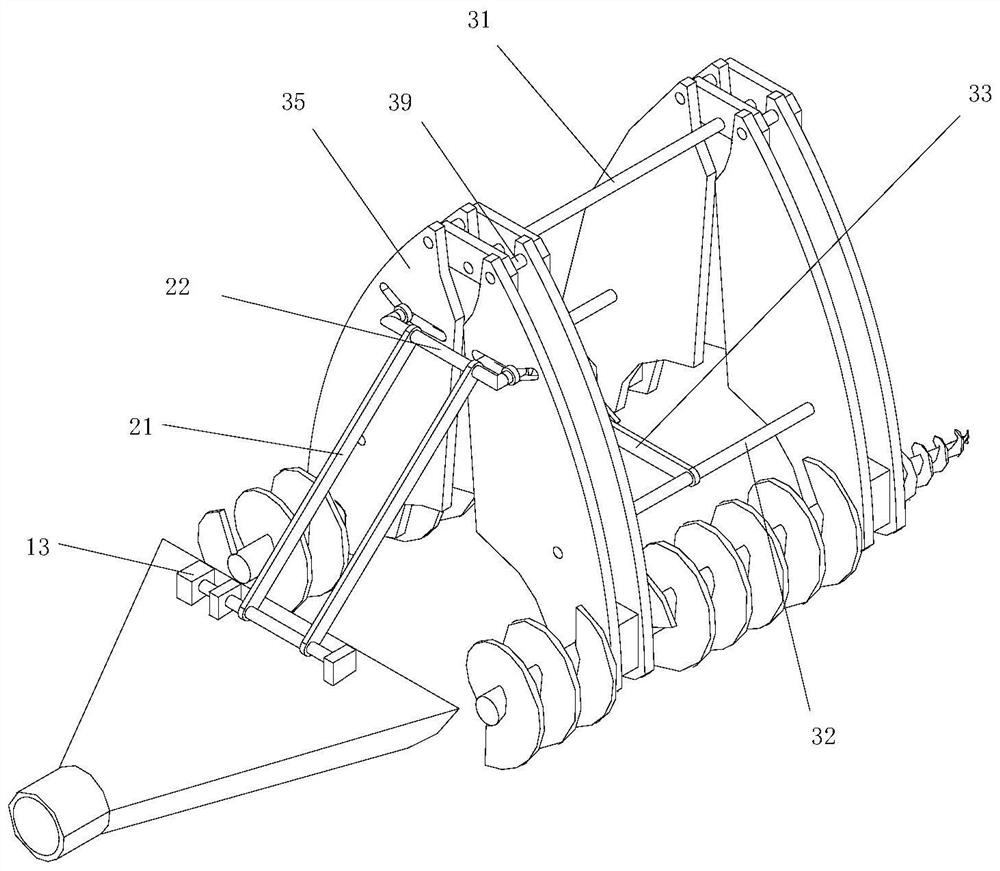

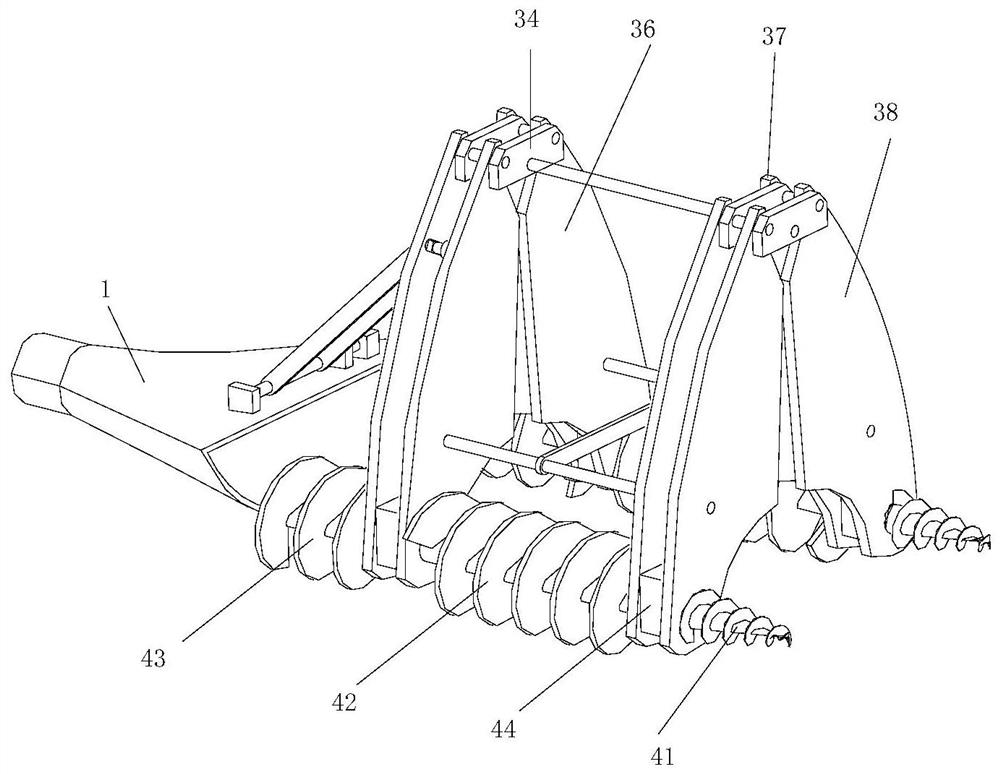

[0064] like Figure 1-11 As shown, a small pipeline dredging vehicle includes a mud suction hood 1 , a mud suction hood adjustment mechanism 2 , a support frame 3 and a screw travel mechanism 4 .

[0065] The bottom of the mud suction cover 1 is an arc that fits the pipe wall. One end of the mud suction port tapers toward the other end of the mud discharge port. The mud discharge port is connected to the sludge pipe through the flange, and the sludge pipe is connected to the ground suction pump. In the state of being attached to the pipe wall, the surface where the suction port is located is perpendicular to the pipe wall.

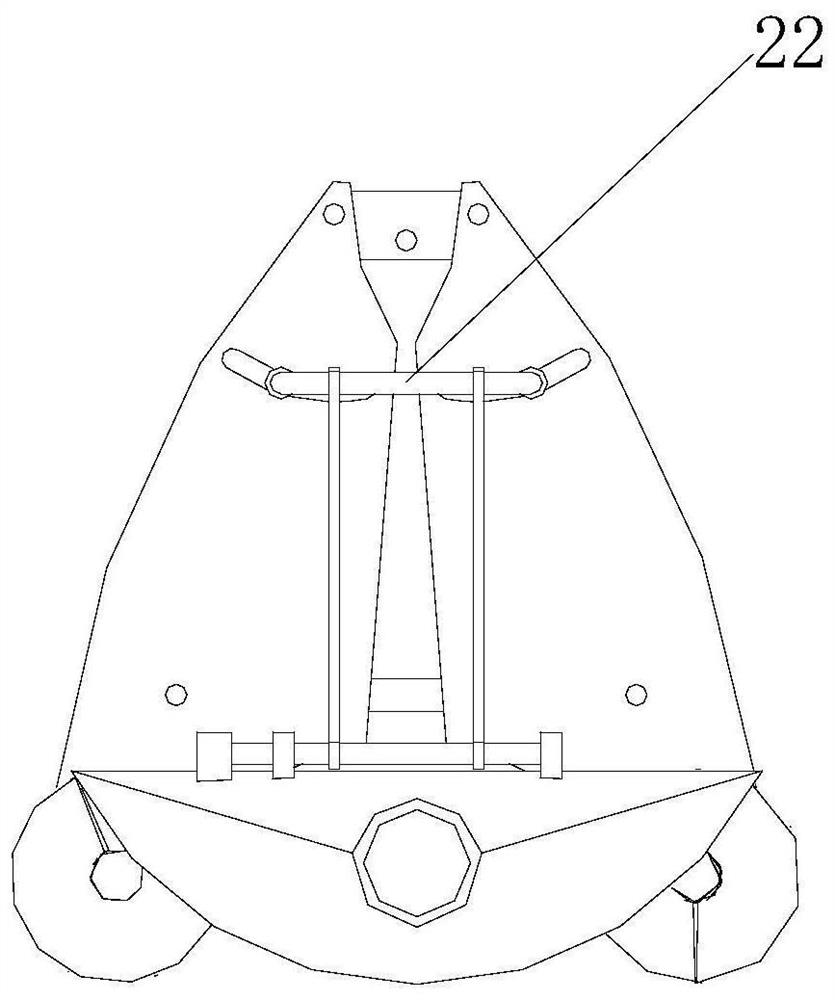

[0066] The mud suction hood adjustment mechanism 2 includes two second connecting rods 21 parallel to each other and a connecting rod fastener 22 connected to the support frame. The connecting rod fastener 22 includes a cross bar and slip rings positioned at two ends of the cross bar. One end is fixedly connected with the top surface of the mud suction ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com