Calibration device for laser displacement sensor

A calibration device and laser displacement technology, applied in the field of laser calibration, can solve problems such as inability to define laser displacement sensors and difficult adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

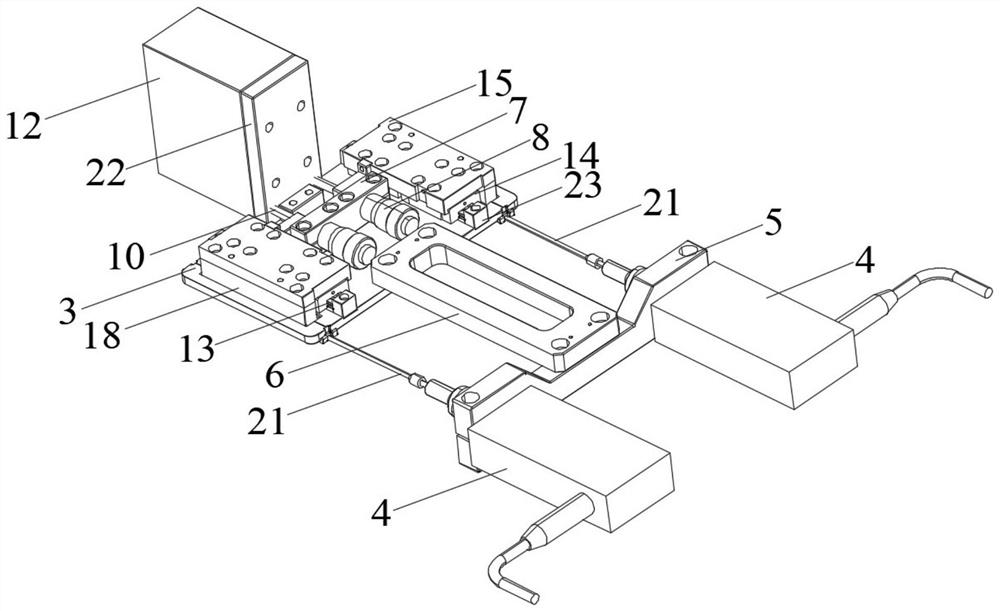

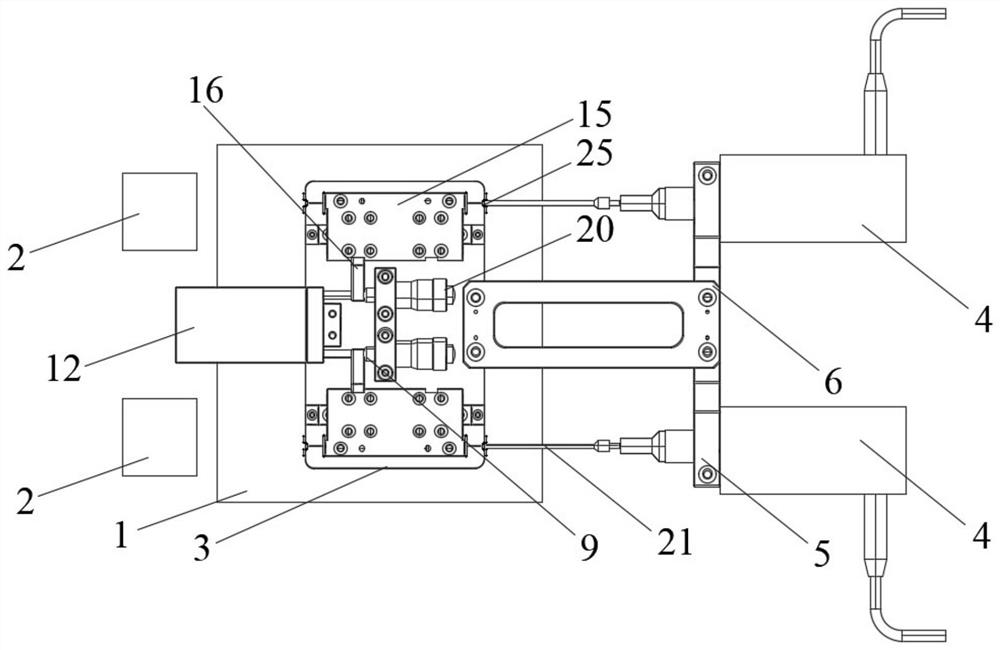

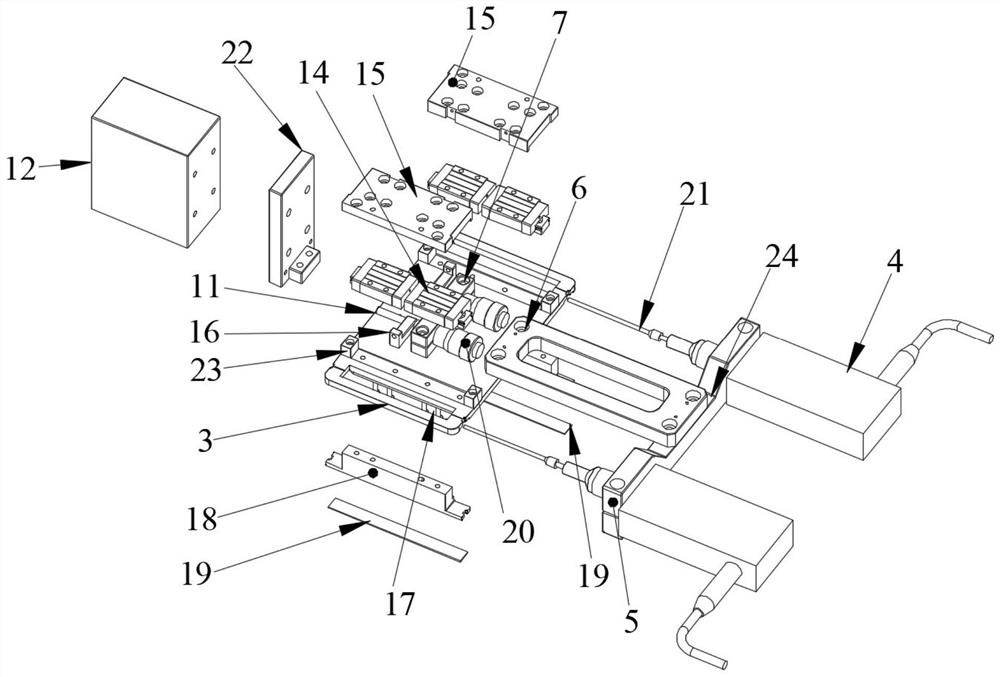

[0018] Such as Figure 1 to Figure 5 As shown, the present invention is used for the calibration device of the laser displacement sensor, after being placed on the special jig 1 for detecting the position of the product to be tested, and the calibration side of the calibration device (being the side close to the counterweight 12) and The laser displacement sensor 2 is relatively set, and the special fixture 1 can be set according to the needs of the manufacturer to detect the product under test. The calibration device in this patent only needs to be placed on the special fixture 1 for detecting the product under test. , no specific requirements are required for the special fixture 1; the calibration device includes a laser calibration plate 3 and a multimeter 4, that is, the laser calibration plate 3 is placed on the special fixture 1 for detecting the position of the product to be tested, and the multimeter 4 is mounted on a fixed On the plate 5, the laser calibration plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com