one-way clutch

A technology for one-way clutches and engaging surfaces, applied in one-way clutches, clutches, automatic clutches, etc., can solve the problems of increased influence, heavy workload, and large number of parts, so as to reduce the number of parts and ease the operation Affordable, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] refer to Figure 1-9 Examples of the present invention will be described. However, the present invention is not limited to this embodiment.

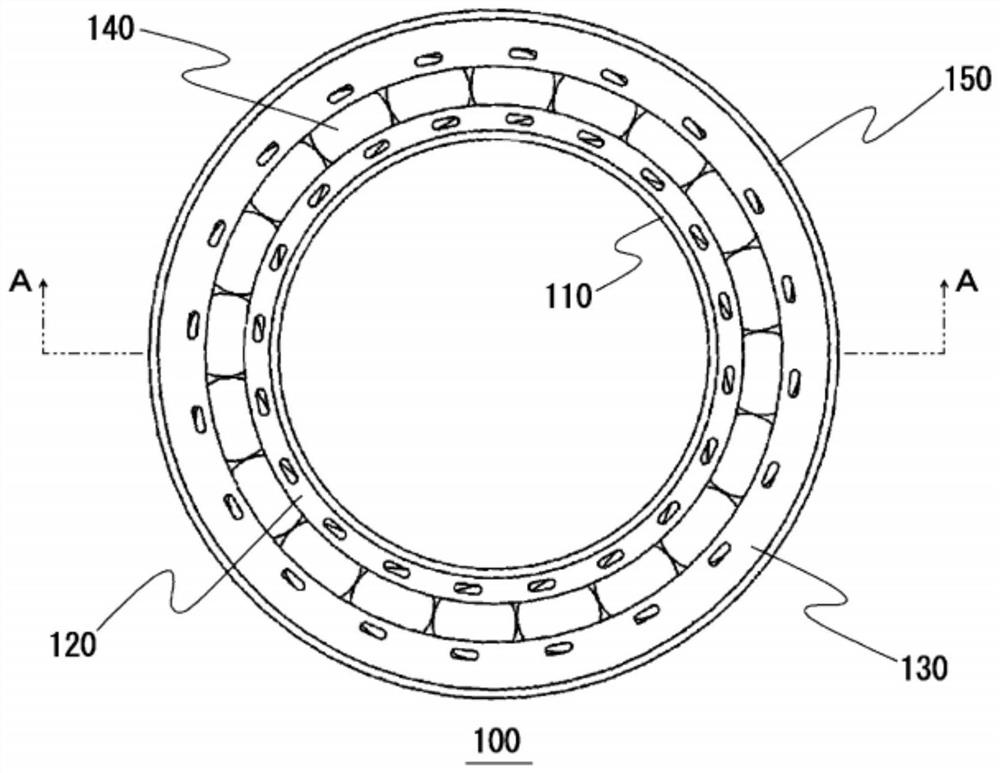

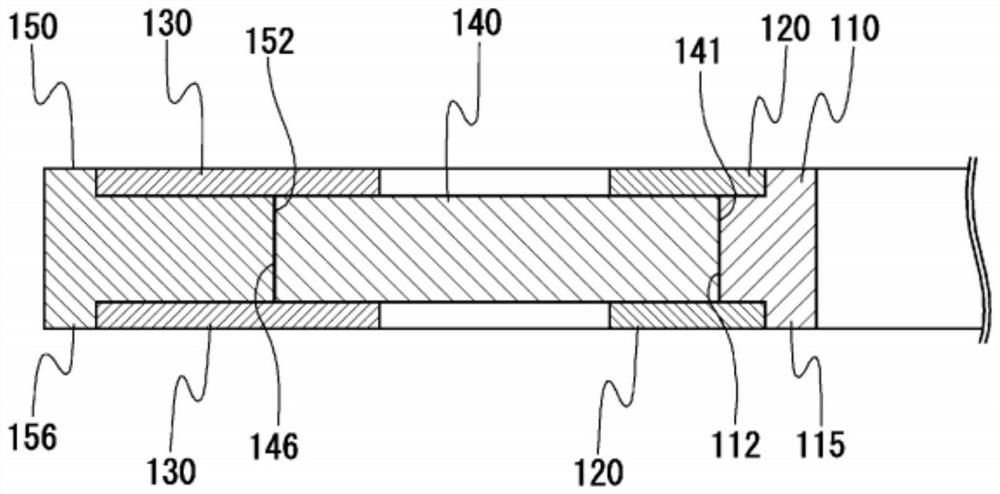

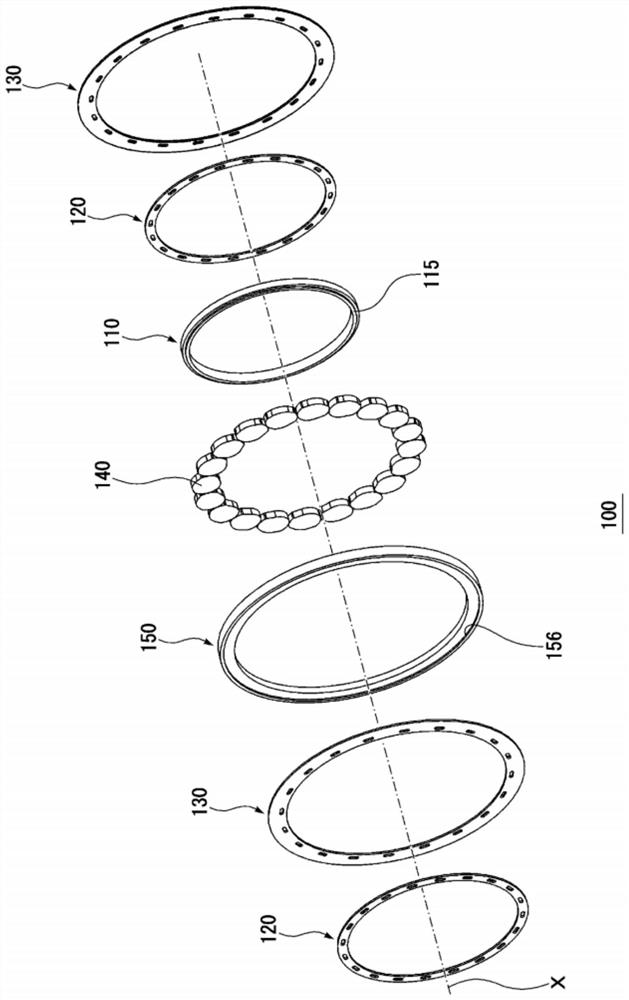

[0034] figure 1 It is a plan view showing a configuration example of the one-way clutch of the present invention. figure 2 yes means figure 1 An enlarged cross-sectional view of a portion of the section on line A-A. image 3 yes figure 1 An exploded perspective view of the one-way clutch shown.

[0035]This one-way clutch 100 includes: an inner ring 110 and an outer ring 150 provided so as to be relatively rotatable on the same X-axis; and a plurality of cams 140 provided between the inner ring 110 and the outer ring 150 .

[0036] Each cam 140 has an inner peripheral engaging surface 141 and an outer peripheral engaging surface 146, and both end surfaces are flat surfaces.

[0037] The inner peripheral engaging surface 141 of the cam 140 is configured to frictionally engage with the outer peripheral engaging surface 112 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com