A gravity-removing positioning method and positioning fixture with an L-shaped mounting frame contactor

A contactor and mounting frame technology, which is applied in the field of edge-sealing fixtures, can solve problems such as large deviation, unqualified device sealing, and inability to meet the precise positioning of contactors, so as to improve positioning accuracy, eliminate welding deformation, and ensure precise positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

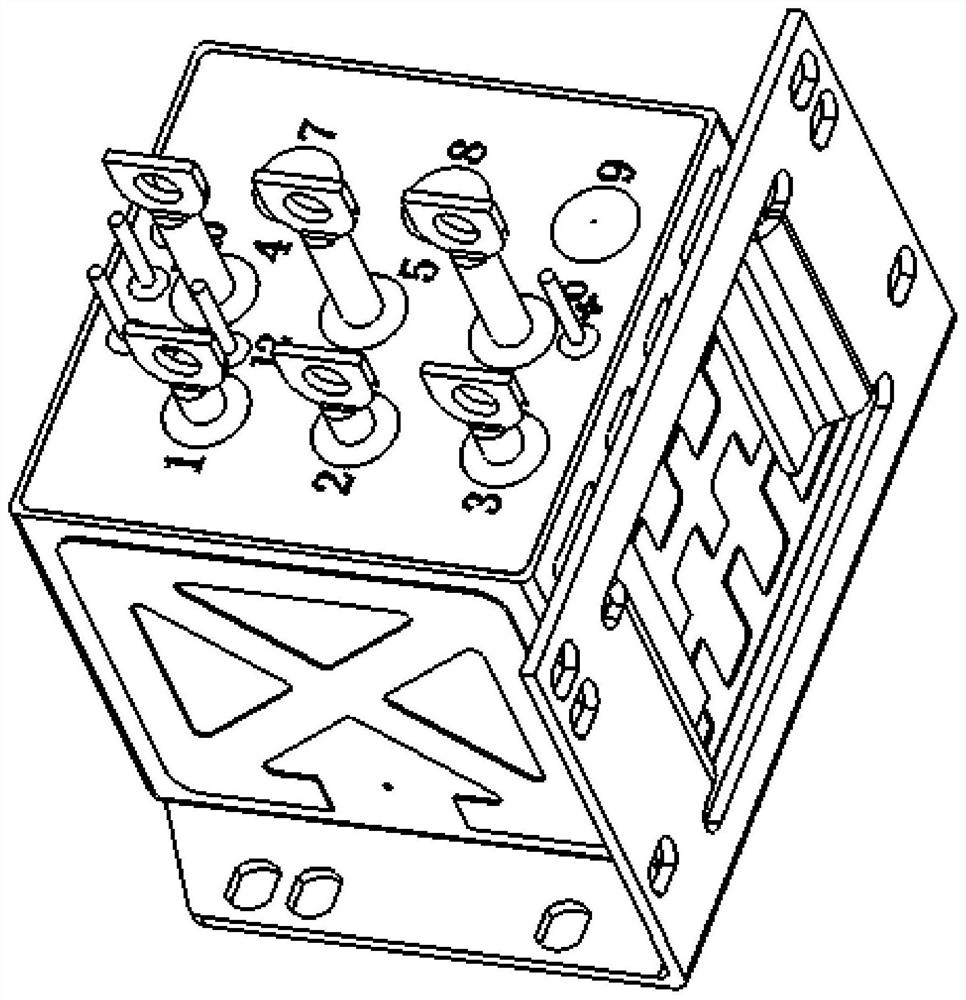

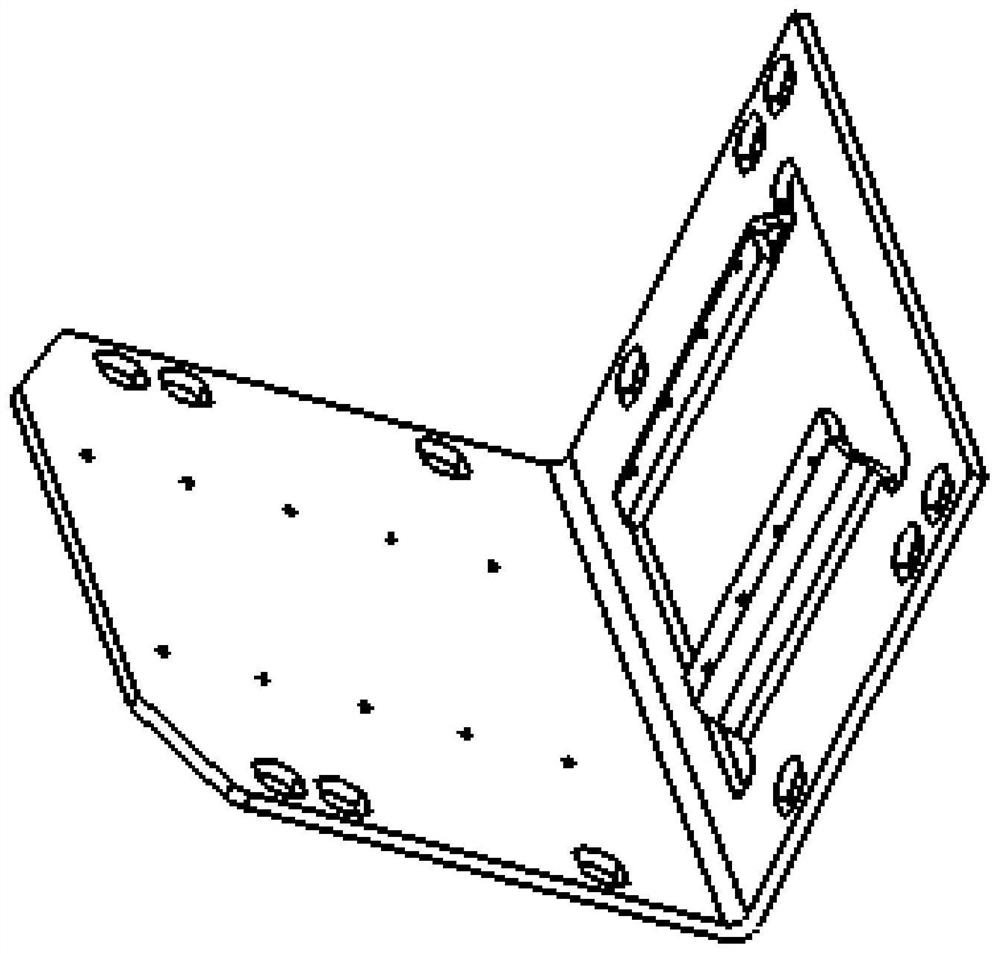

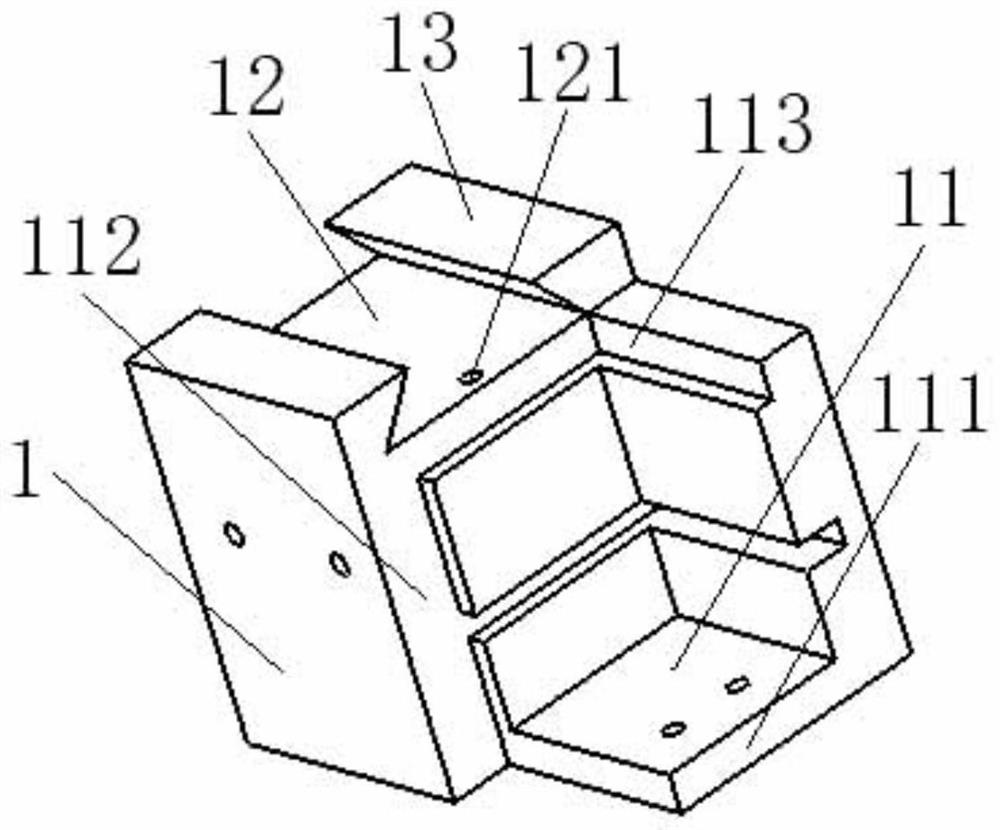

[0024] Herein, the technical solutions provided by the present invention will be further introduced in detail with reference to the accompanying drawings and specific embodiments.

[0025] In order to solve the problem that the existing gravity positioning method has low positioning accuracy and cannot meet the precise positioning of the contactor in the laser welding technology, the present invention provides a gravity-removing positioning method with an L-shaped mounting frame contactor. The method Position the edge contactor with the L-shaped mounting bracket so that the bottom surface is suspended.

[0026] The positioning method can be implemented by any positioning fixture. The specific steps are to first position the edge-to-be-sealed contactor with the L-shaped mounting bracket in the fixture, and then lift the edge-to-be-sealed contactor with the L-shaped mounting bracket. The bottom surface is suspended in the air to complete the positioning, and then the edge is wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com