Rotating mold for rotational moulding continuous forming

A rotary and mold technology, applied in the direction of coating, etc., can solve the problems of poor stability, inability to perform injection molding at the same time, defective products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

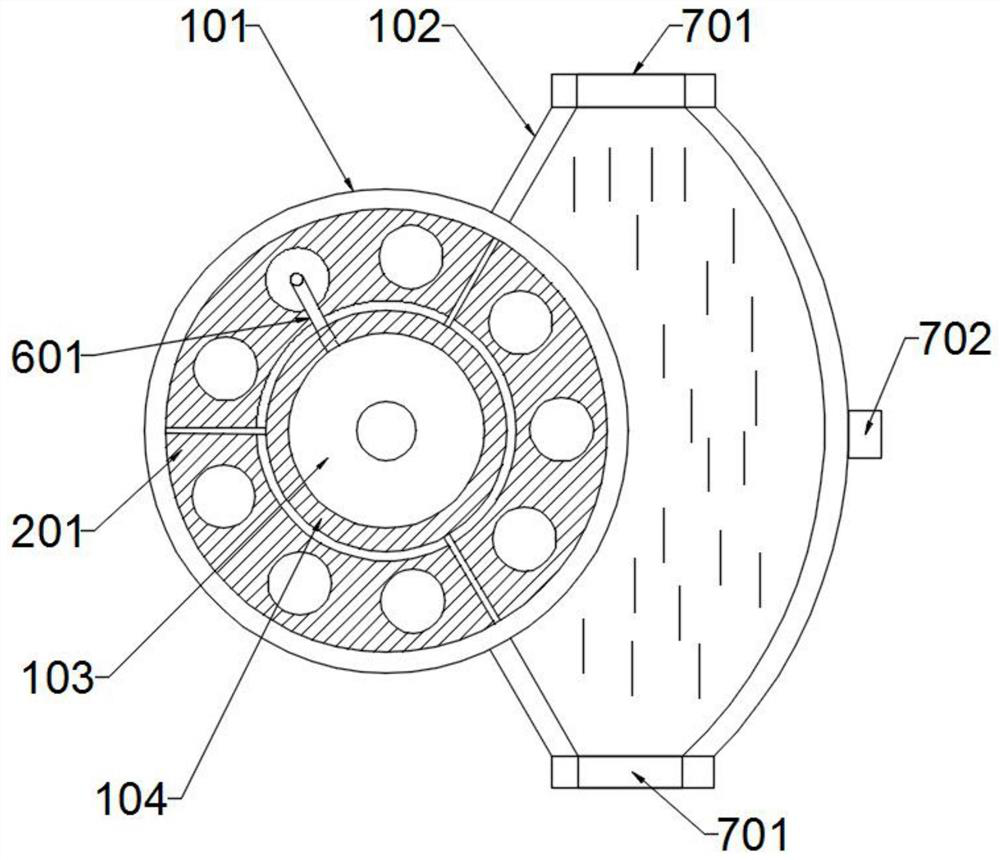

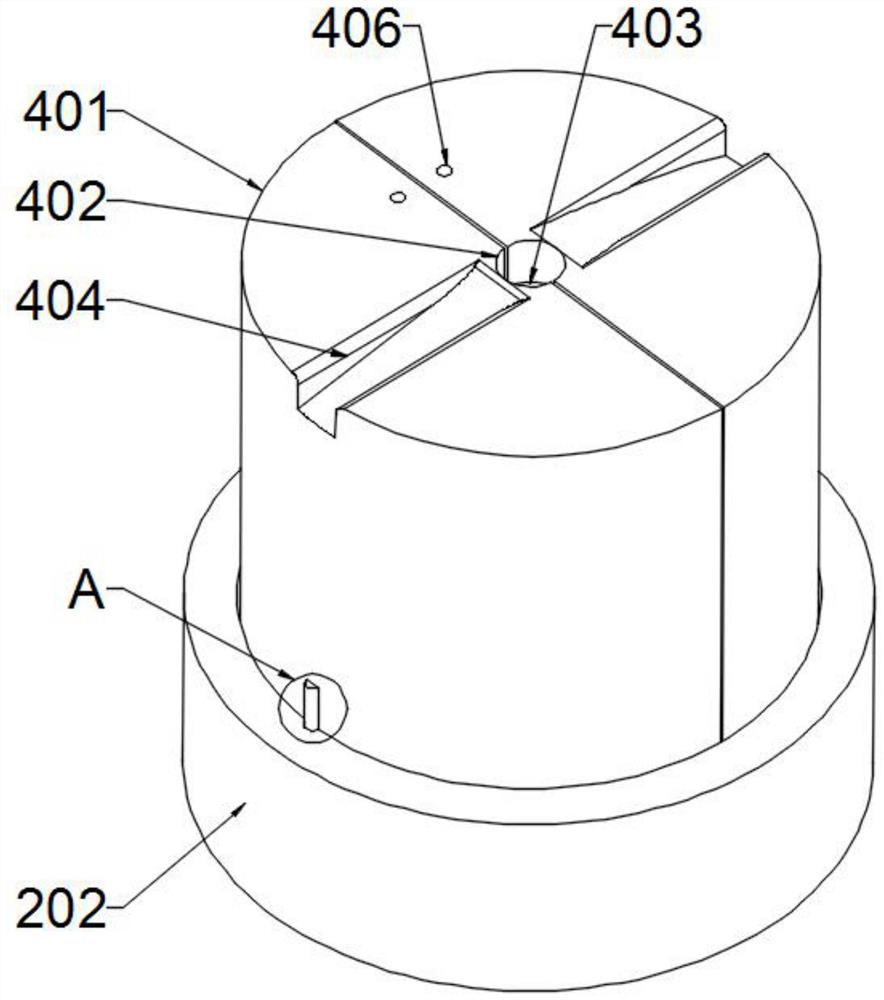

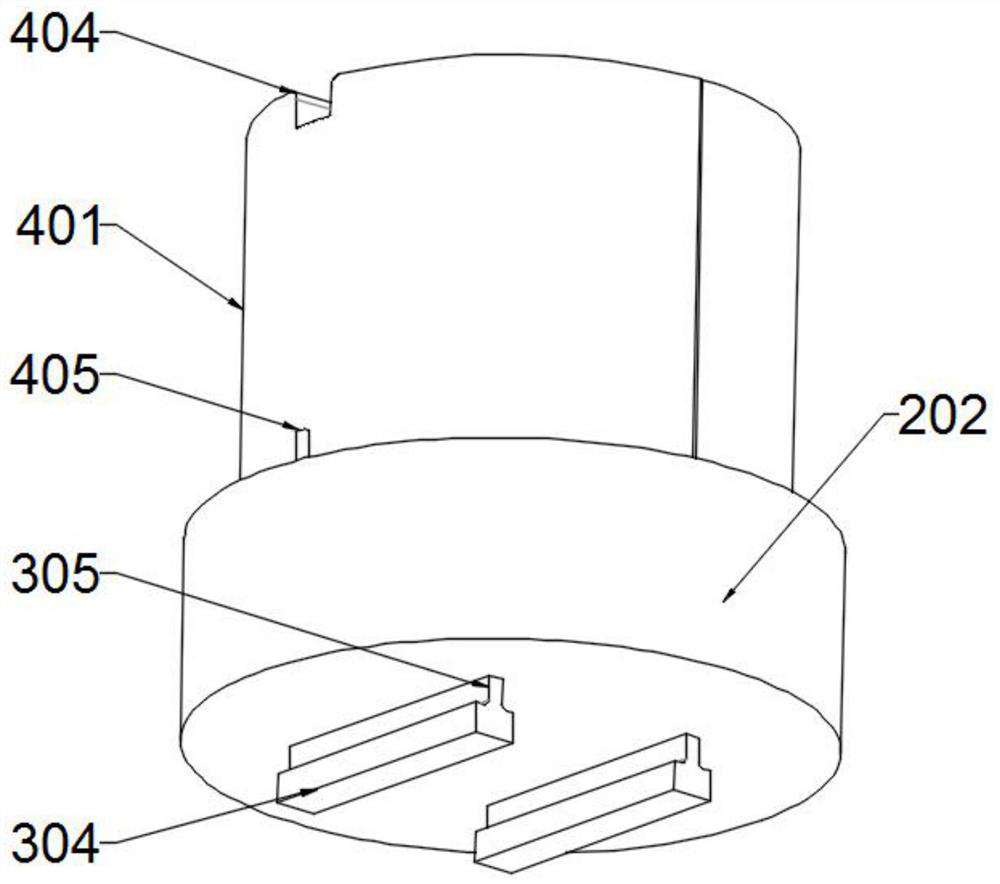

[0027] Example: such as Figure 1-7 As shown, the rotary mold for rotomolding continuous molding includes a support component, a rotating fixed component, an elastic component, a forming component, an isolation component, a pass-through component, and a cooling component. For the function of other components, there is a rotating and fixing component above the support component, which plays the role of controlling the movement of the mold, and an elastic component is arranged under the rotating and fixing component, which controls the small elastic displacement of the mold. There is a forming component on the component, the forming component plays the role of completing the basic mold shaping operation, an isolation component is arranged above the rotating fixed component, and the isolating component plays the role of partitioning the rotating fixed component, and the supporting component is provided with a through-close Components, the opening and closing components play the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com