Automobile glass curing liquid PE container blow molding die

A technology for automotive glass and blow molding molds, which is used in household appliances, other household appliances, household components, etc., and can solve the problems of mold wear, impact on accuracy, and wear of the inner wall of the guide sleeve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

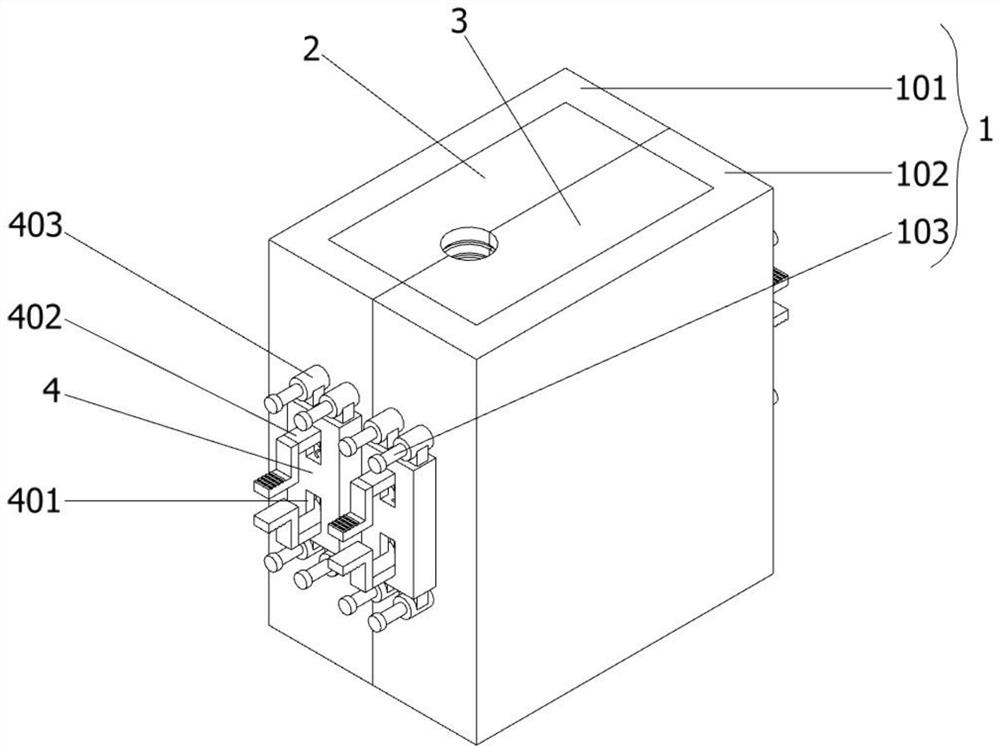

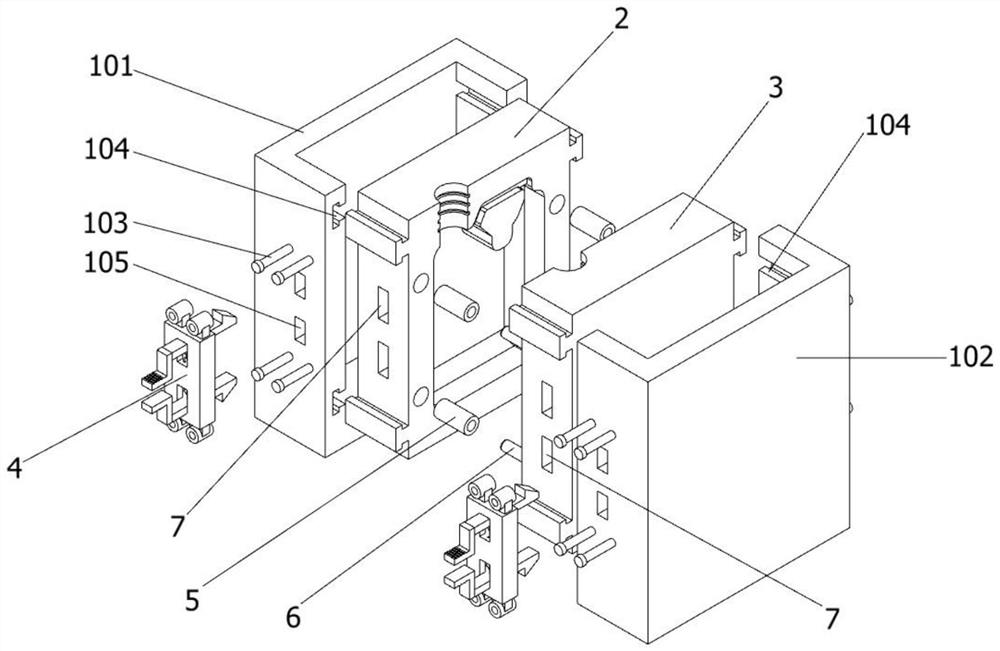

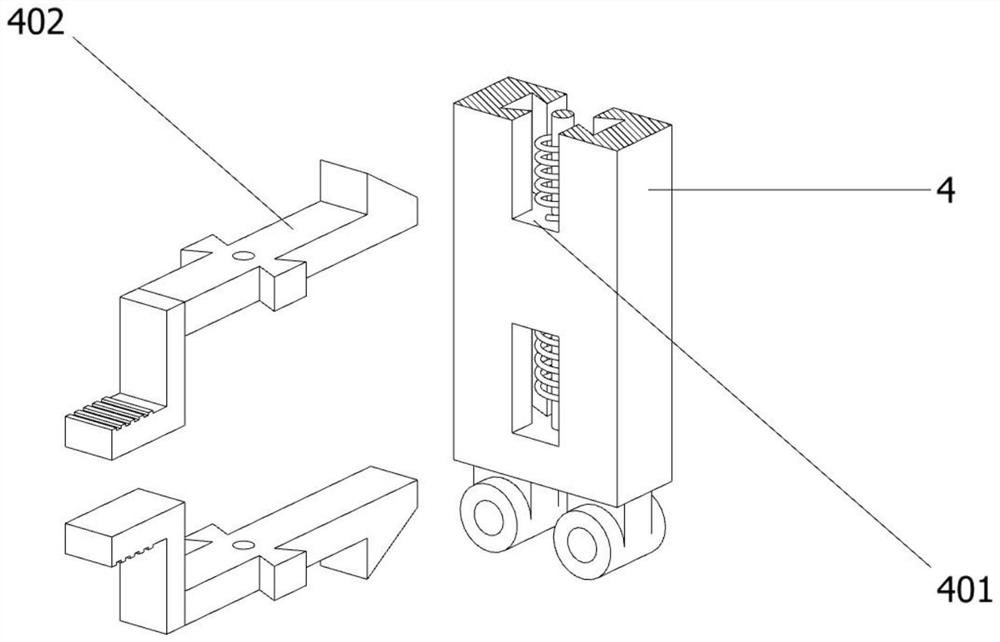

[0028] as attached figure 1 to attach Figure 6 Shown:

[0029]The present invention provides a blow molding mold for PE container of automobile glass curing liquid, which includes a shell 1, a first mold 2 and a second mold 3 are installed inside the shell 1, and the shell 1 includes a first installation shell 101, a second installation shell 102, the limit slide bar 103, the T-shaped chute 104 and the rectangular card hole 105, the left and right sides of the first installation shell 101 and the second installation shell 102 are provided with two T-shaped chute 104 in a symmetrical shape up and down, and The T-shaped chute 104 on the first installation shell 101 is slidably connected with the T-shaped slider on the first mold 2 , and the T-shaped chute 104 on the second installation shell 102 is slidably connected with the T-shaped slider on the second mold 3 . Make the installed first mold 2 and the second mold 3 more stable, the left and right ends of the first installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com