Rear door automatic elevator for electric vehicle

An automatic lift, electric vehicle technology, applied in the arrangement, transportation and packaging of vehicle parts, pedals or ladders, etc., can solve the problems of not having electric lifts, affecting the efficiency of handling, convenient use, inconvenient to transfer goods up and down, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

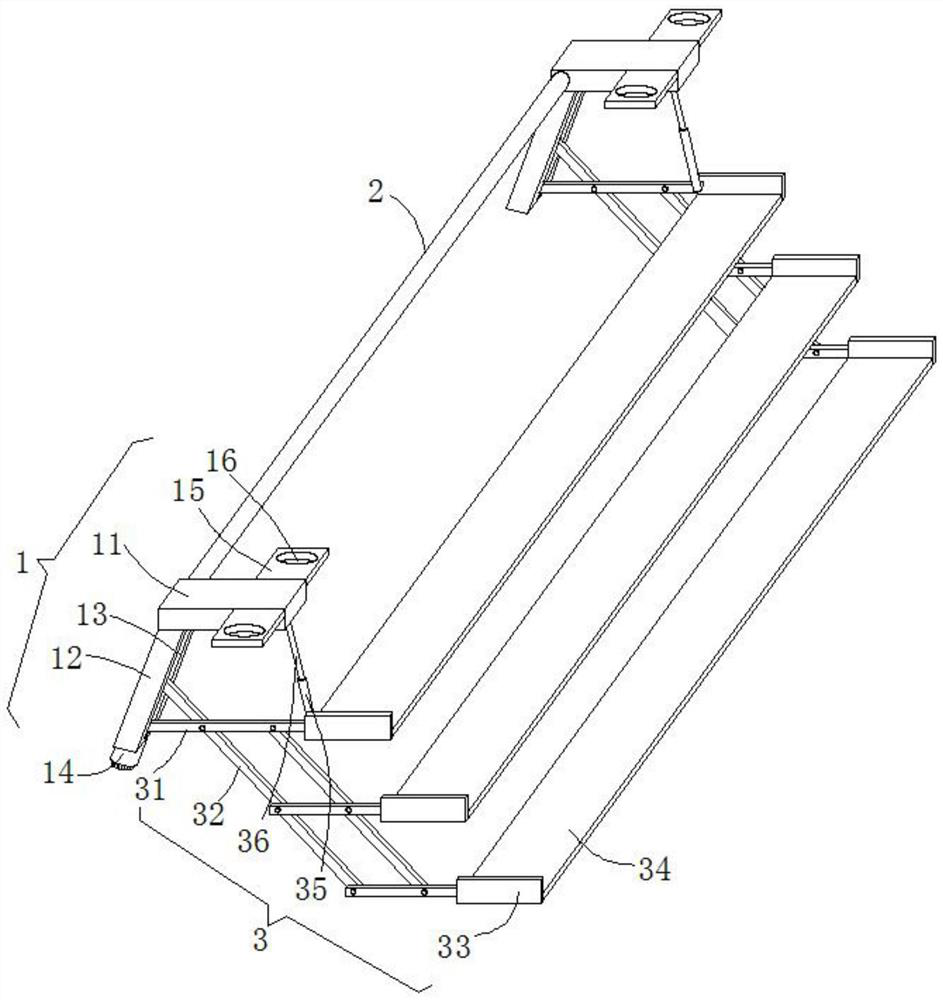

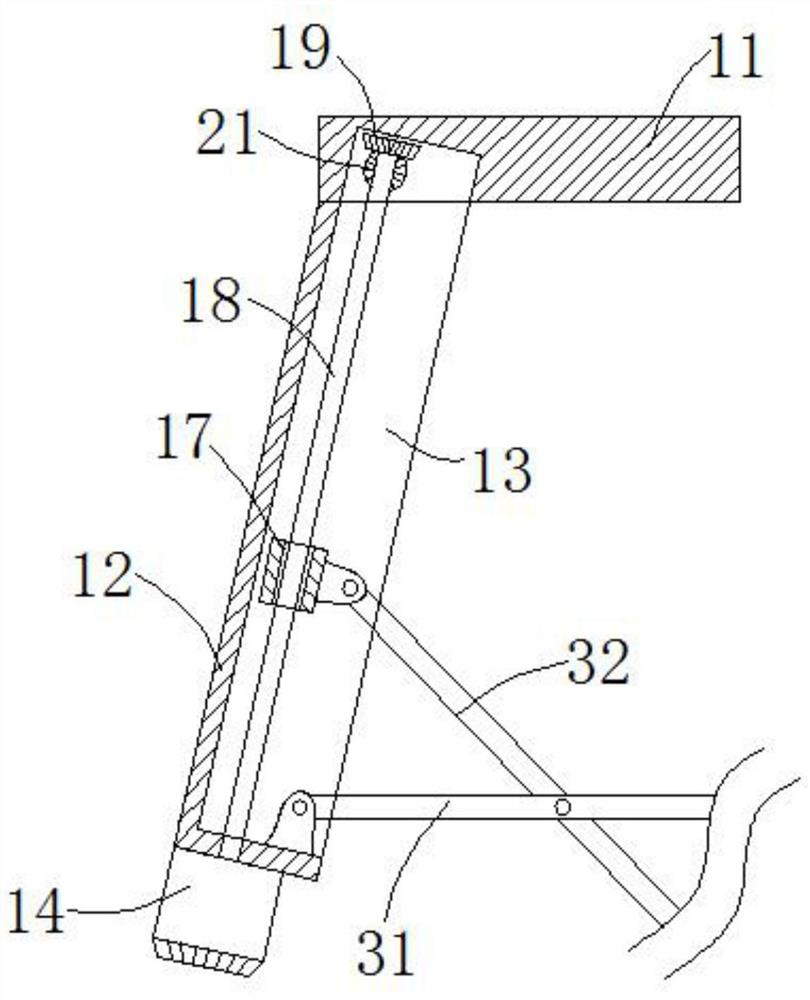

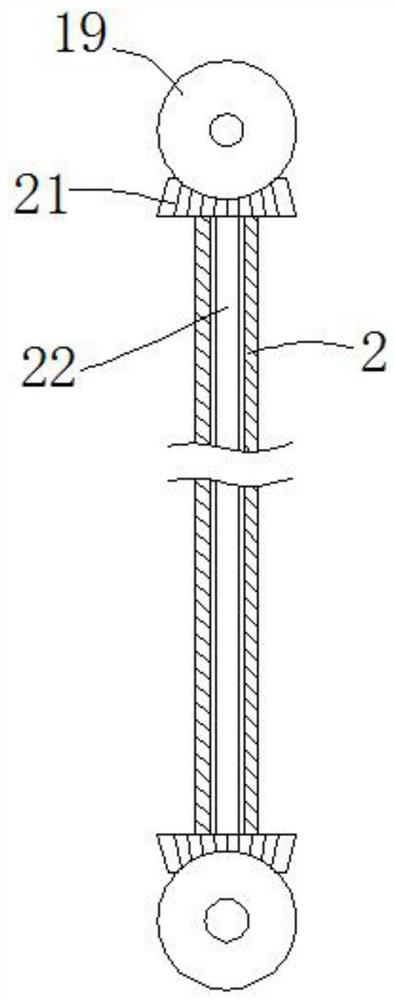

[0023] see Figure 1-3 , the present embodiment provides an automatic rear door elevator for electric vehicles, including two installation support mechanisms 1, two stepping mechanisms 3 and transmission sleeves 2, and the two installation support mechanisms 1 include installation plates 11 and adjustment plates 12. The two installation support mechanisms 1 are distributed front and back, and the left ends of the opposite side walls of the two installation plates 11 are fixedly plugged with the axial ends of the drive sleeve 2 respectively, and each adjustment plate 12 is welded on the On the left side of the bottom end surface of each mounting plate 11 , the two pedaling mechanisms 3 each include a plurality of first articulated rods 31 , a plurality of second articulated rods 32 and a plurality of mounting back plates 33 .

[0024] The right end surface of each adjustment plate 12 is provided with an adjustment groove 13 extending to the inner cavity of each corresponding in...

Embodiment 2

[0030] see Figure 1-3 , further improvements have been made on the basis of Example 1:

[0031] The front and rear sides of the right end of each mounting plate 11 are fixedly provided with extension plates 15, and each extension plate 15 is provided with mounting holes 16, and the mounting holes 16 of each extending plate 15 are penetrated by bolts to facilitate the installation of the mounting plate 11. Fixed installation.

[0032] Two installation backboards 33 on the uppermost side are hinged with telescopic sleeves 35 on the left side of the opposite side wall through pin shafts, and the tops of the two telescopic sleeves 35 are slidingly inserted with T-shaped telescopic rods 36, and two T-shaped telescopic rods 36 The top of the top is respectively hinged with the right side of the bottom end face of the two mounting plates 11, and the telescopic sleeve 35 inner cavity is free to expand and contract by the T-shaped telescopic rod 36, which can enhance the hoisting sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com