Riverway water pollution floating garbage cleaning device

A technology for garbage cleaning and water pollution. It is used in the cleaning of open water surfaces, water conservancy projects, filtration and separation, etc. It can solve the problem of manual salvage and labor consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

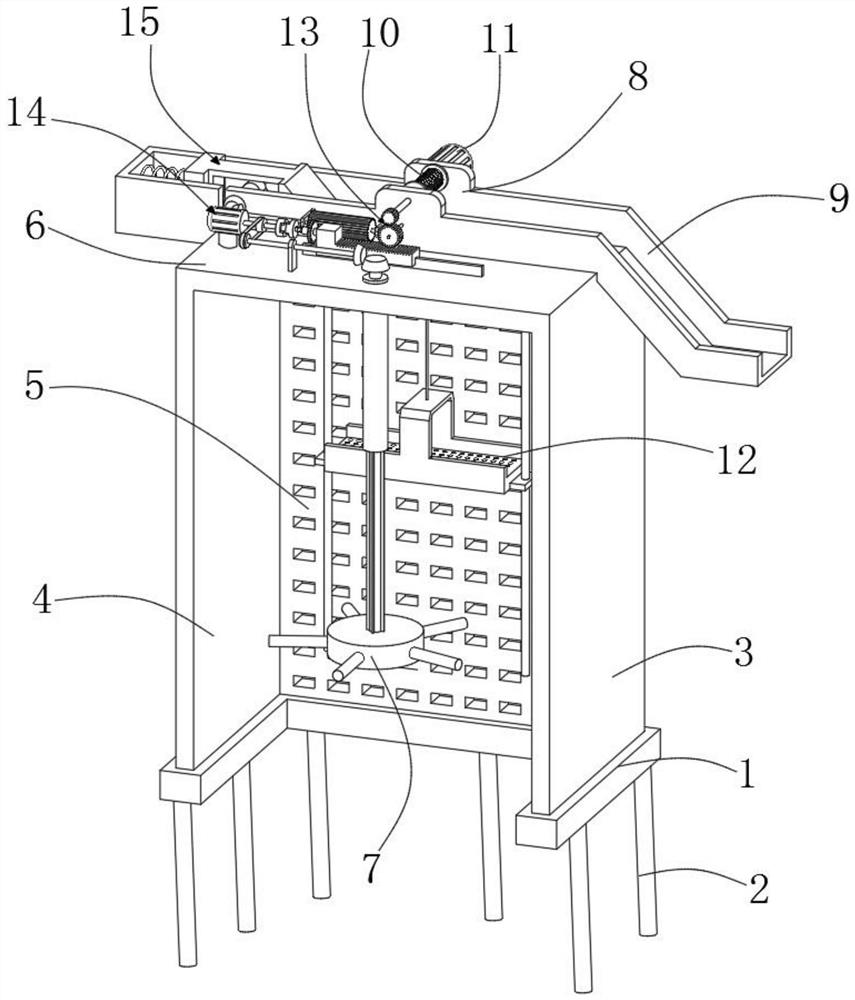

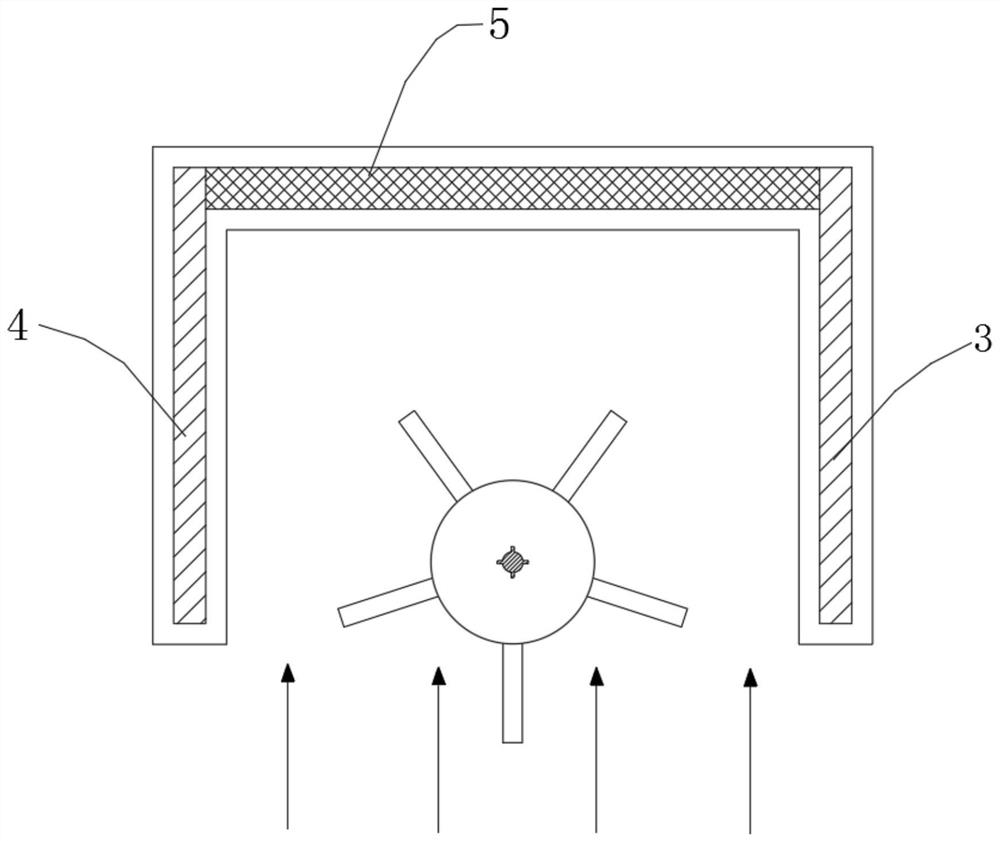

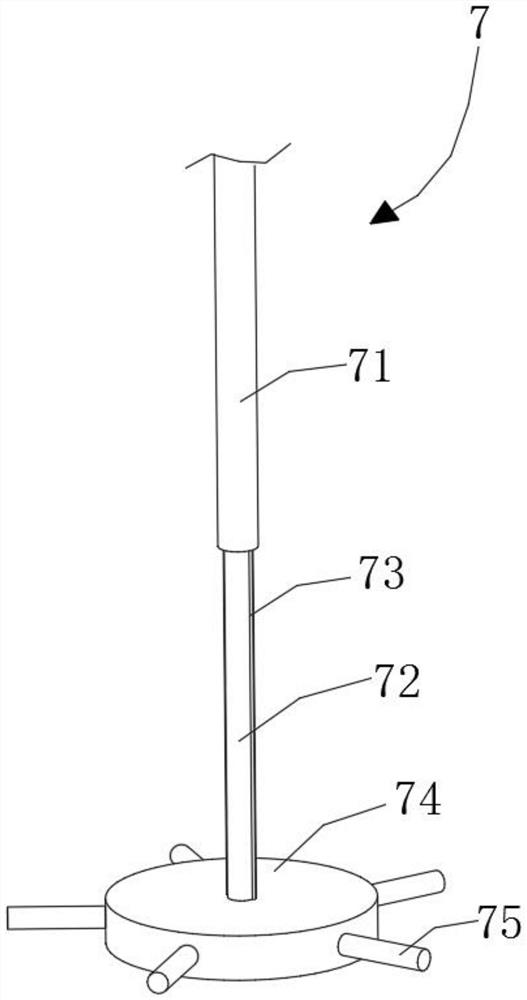

[0031] refer to Figure 1-4, a kind of river course water pollution floating rubbish cleaning device, comprises base 1, and the bottom of base 1 is fixedly installed with several support columns 2, and support column 2 is the concrete cylinder poured on the bottom of river downstream; The top side of base 1 is fixedly installed There is a first baffle 3, and a second baffle 4 is fixedly installed on the other side of the top of the base 1, and the second baffle 4 and the first baffle 3 are installed on both sides of the river, and the second baffle 4 and the first baffle The plates 3 are all anti-corrosion steel plate structures; a filter plate 5 is fixedly installed between the second baffle plate 4 and the first baffle plate 3, a top plate 6 is fixedly installed on the top of the filter plate 5, and a Stirring mechanism 7, stirring mechanism 7 comprises sleeve 71, slide bar 72, some first stop blocks 73, floating plate 74 and some driving rods 75, the top end of sleeve 71 ru...

Embodiment 2

[0036] refer to Figure 1-12 As another preferred embodiment of the present invention, the difference from Embodiment 1 is that a guide seat 8 is installed on the top of the top plate 6, and a reel 10 is installed on the inner side of the guide seat 8, and the outer side of the guide seat 8 is fixedly installed with a corresponding The second motor 11, the output shaft of the second motor 11 is fixedly connected with the reel 10, the inside of the filter plate 5 is equipped with a salvage mechanism 12, and the salvage mechanism 12 includes a salvage bushing 121, two guide rods 122, a mounting frame 123, Steel cable 124 and two limit plates 125, the tops of two guide rods 122 are all fixedly connected with the bottom wall of top plate 6, two limit plates 125 are respectively fixedly installed on both sides of salvage slipper 121, two guide rods 122 runs through the corresponding limiting plate 125 and is slidably connected with the limiting plate 125. The bottom ends of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com