Desert sand fixation device for environmental protection

A technology for environmental protection and desert, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of short sand fixation effect, low work efficiency, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

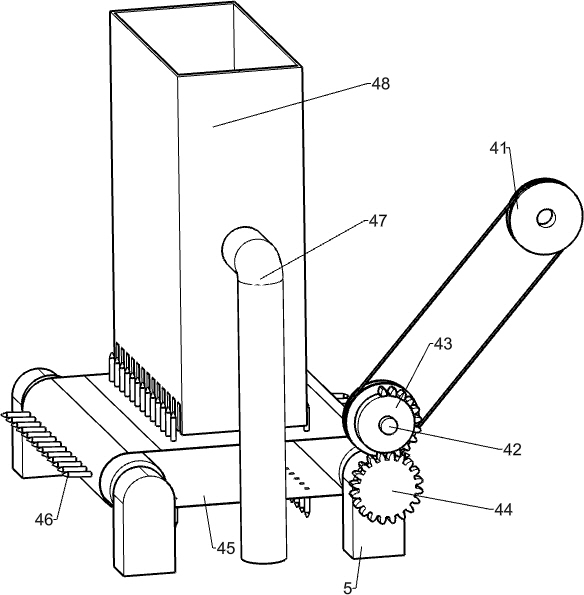

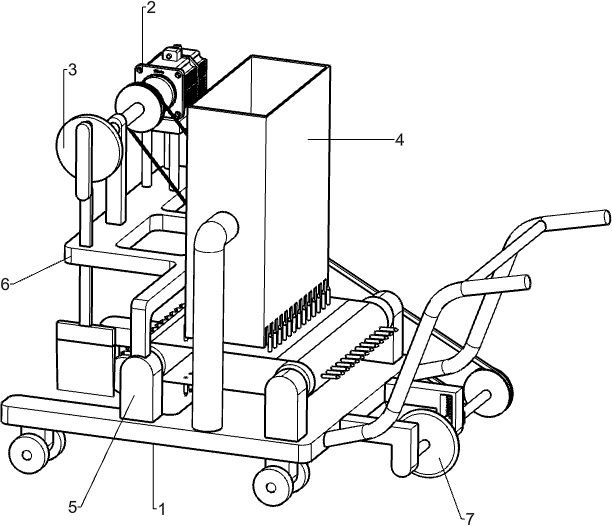

[0040] A desert sand-fixing device for environmental protection, such as figure 1 As shown, include cart 1, motor 2, grass plugging mechanism 3, grass lowering mechanism 4, fixed block 5, mounting frame 6 and slotting mechanism 7, both sides of front and back of cart 1 top are all left and right symmetrically provided with fixed block 5, Mounting frame 6 is connected between the tops of the two fixed blocks 5 on the left side, motor 2 is installed on the rear side of the mounting frame 6 tops, and a plugging mechanism 3 is connected between the output shaft of the motor 2 and the front side of the mounting frame 6 tops , between the grass plugging mechanism 3 and the fixed block 5, the grass-lowering mechanism 4 is connected, and the right side of the cart 1 is connected with the grass-lowering mechanism 4 with a slotting mechanism 7.

[0041] When it is necessary to fix sand in the desert, the user first places the straw in the grass-lowering mechanism 4, then starts the moto...

Embodiment 2

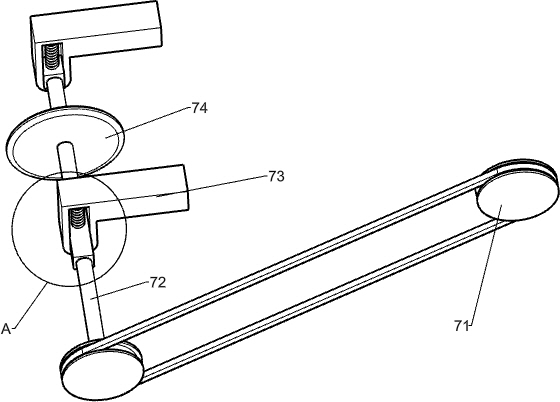

[0043] On the basis of Example 1, such as figure 2 As shown, the grass plugging mechanism 3 includes a first rotating shaft 31, a bearing seat 32, a disc 33, a first rotating column 34 and a grass plugging rod 35, and the front side of the mounting bracket 6 top is provided with a bearing seat 32, and the bearing seat 32 top rotates is connected with the first rotating shaft 31, the rear side of the first rotating shaft 31 is connected with the output shaft of the motor 2, the front side of the first rotating shaft 31 is provided with a disc 33, and the eccentric position of the front side of the disc 33 is rotationally connected with the first rotating shaft Post 34, mounting frame 6 front sides are slidingly connected with plug grass bar 35, and plug grass bar 35 tops are connected with the rotation type of first rotating post 34 bottoms.

[0044] When the motor 2 starts, the motor 2 rotates through the first rotating shaft 31 to drive the lower groove mechanism to rotate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com