Prefabricated module for constructing deformation joint and deformation joint waterproof construction method

A construction method and technology of deformation joints, applied in building structures, water conservancy projects, building components, etc., can solve problems such as high hydrostatic pressure, deformation joints that are easy to leak, difficult to maintain, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

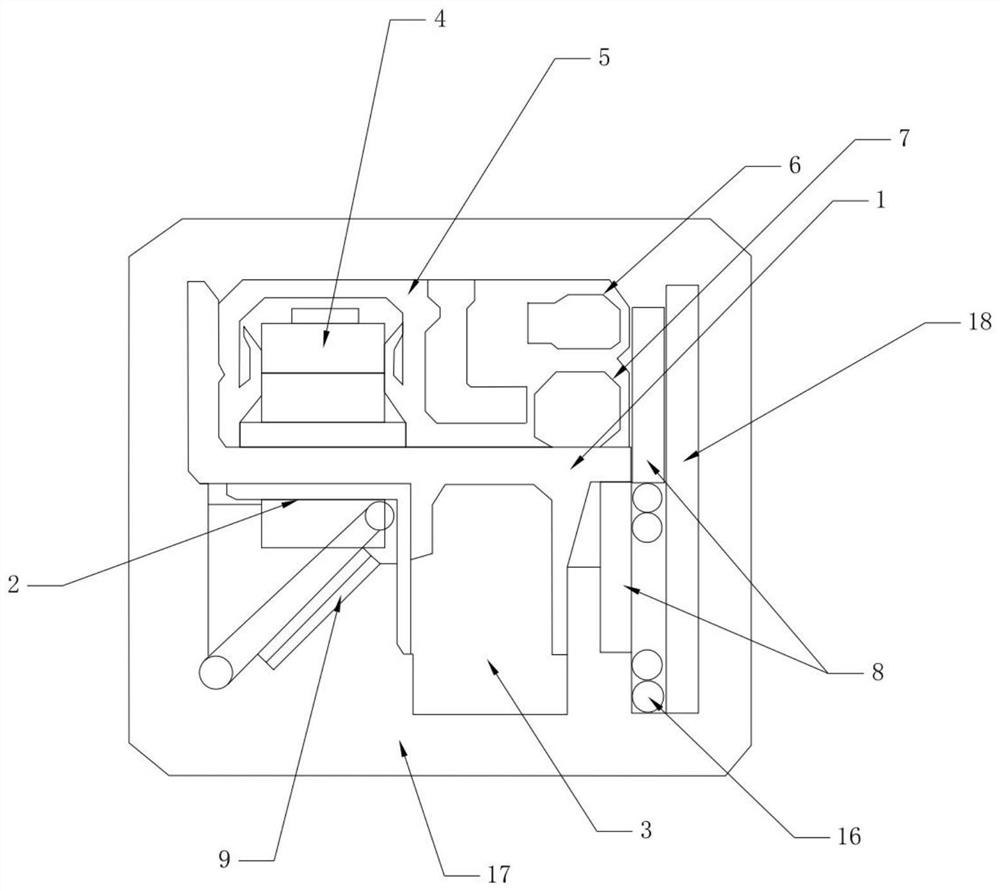

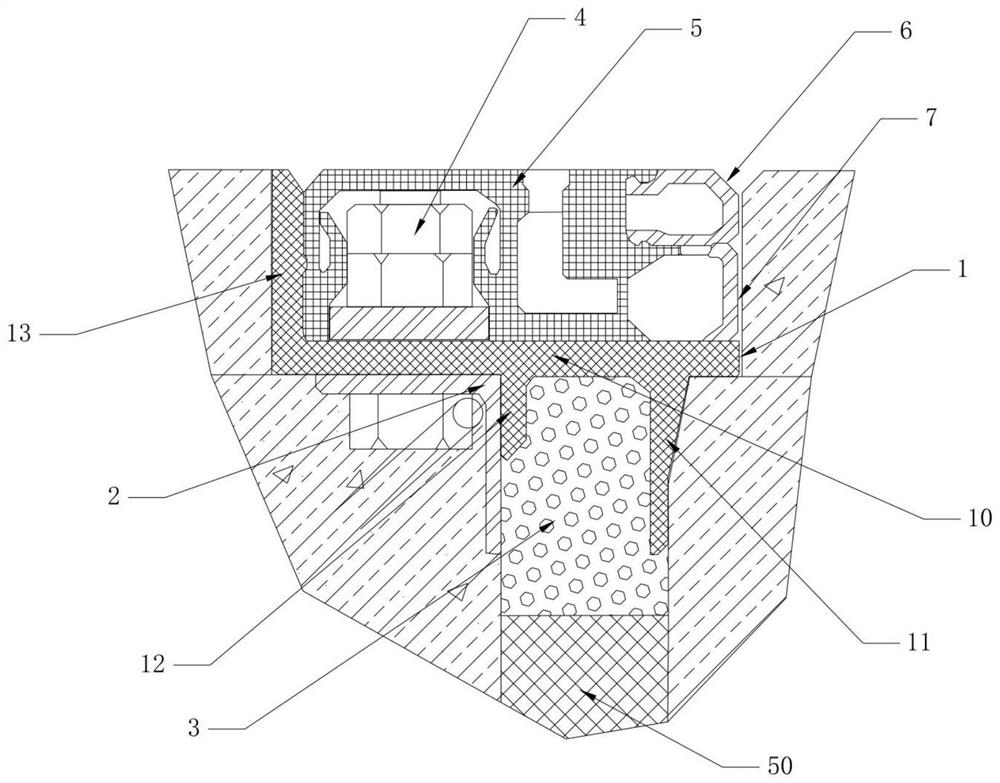

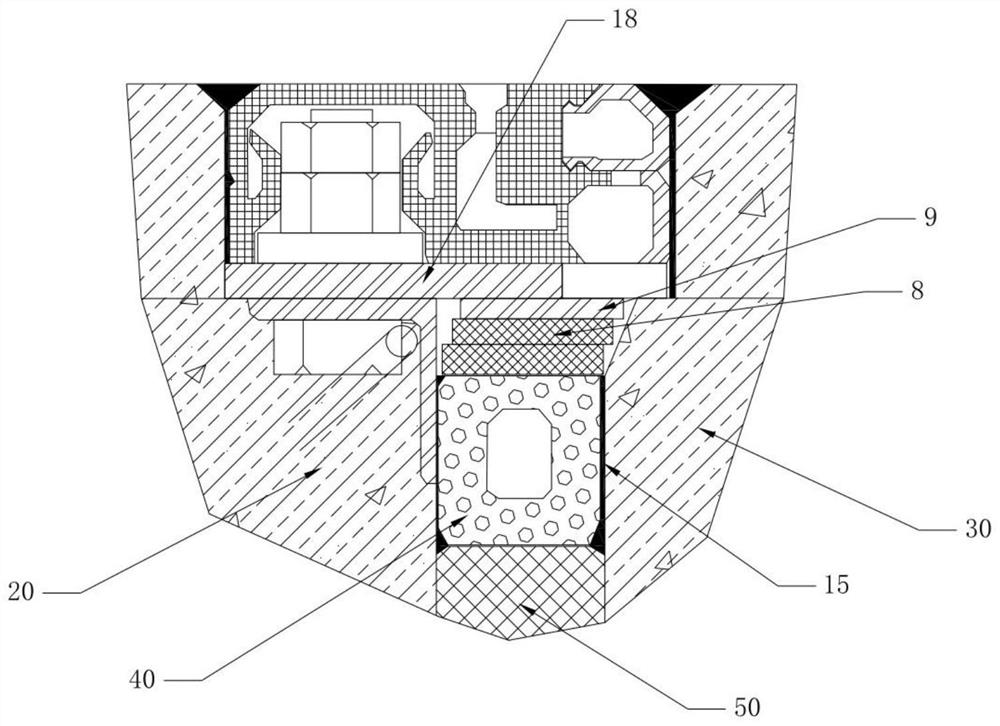

[0034] The first embodiment of the present invention provides a prefabricated module for constructing deformation joints, such as figure 1 As shown, it includes an L-shaped formwork 1, and the L-shaped formwork includes a horizontal wall 10 and a vertical wall 13; it also includes angle steel 2, anchors, protective covers 5 and several accessories, which are prefabricated and assembled in a factory and packed by a packing box 17 Transported to the construction site for direct use. The accessories include a steel pressure plate 18, a stainless steel force transmission plate 9 with a width smaller than that of the deformation seam, and a plurality of polyethylene protective plates 8 with the same width as the deformation seam for filling the deformation seam. The L-shaped mold plate 1 is used as a formwork when pouring deformation joints, the main body of the mold plate is “L” shaped, and the design standard length of each section of the mold plate is 600 mm. The lower part has...

Embodiment 2

[0036] The second embodiment of the present invention provides a waterproof construction method for deformation joints based on the prefabricated modules for constructing deformation joints in Embodiment 1, including:

[0037] Firstly, before the deformation joint is poured, the prefabricated modules of the deformation joint are accurately misplaced and positioned on both sides of the joint, and clamped at the joint; the end of the anchor bar on the angle steel is spot welded on the steel bar;

[0038] Next, set up the formwork, pre-embed the XPS formwork of not less than 45kg / m3 in the joint, and pour concrete on both sides of the deformation joint;

[0039] When supporting the mold at the seam of the side wall, accurately misplace the positioning, and clamp the mold plate 1, the protective cover 5, the embedded parts and the upper cover of the inner package together in the side mold, and only expose the foot rib at the lower part of the mold plate 11 and 12 and their own har...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com