Typical formwork for concrete drainage pipe junction plaster band construction, and construction method

A technology for shaping formwork and concrete, applied in formwork/formwork/work frame, sewer pipe system, non-removable pipe connection, etc., which can solve the problems of slurry leakage, increased engineering cost and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

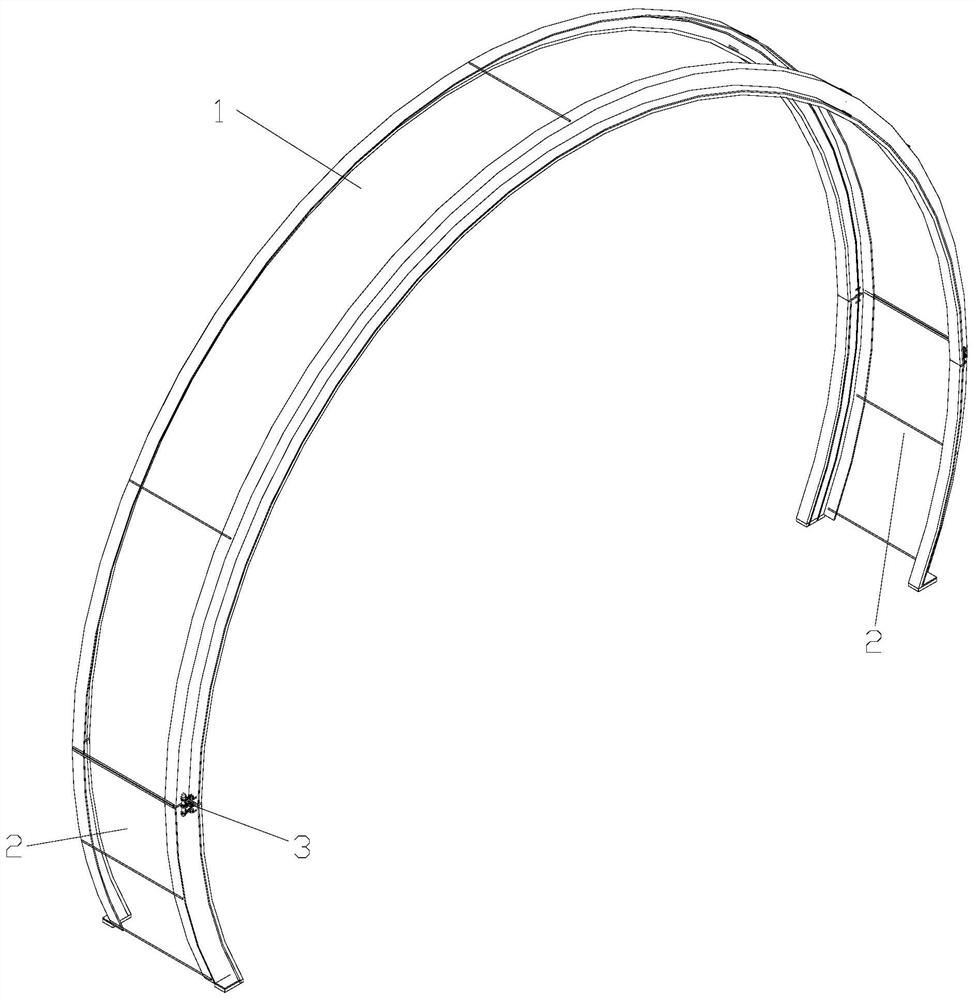

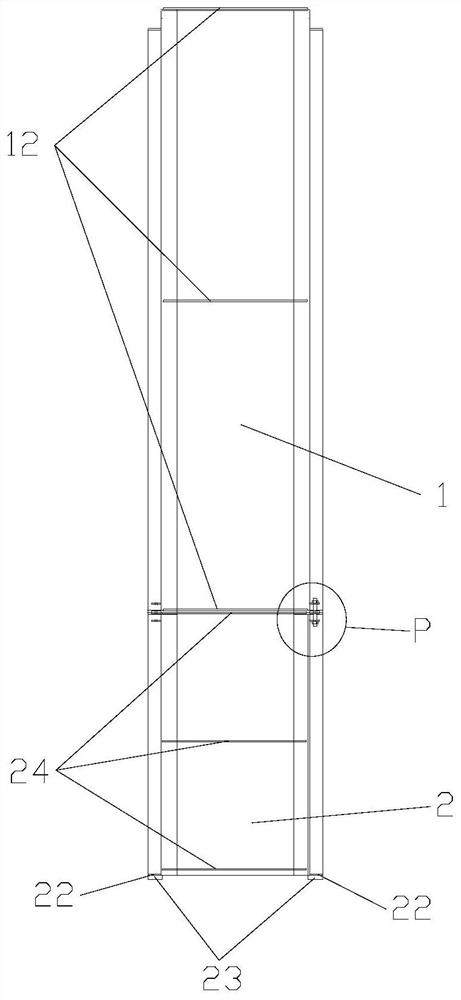

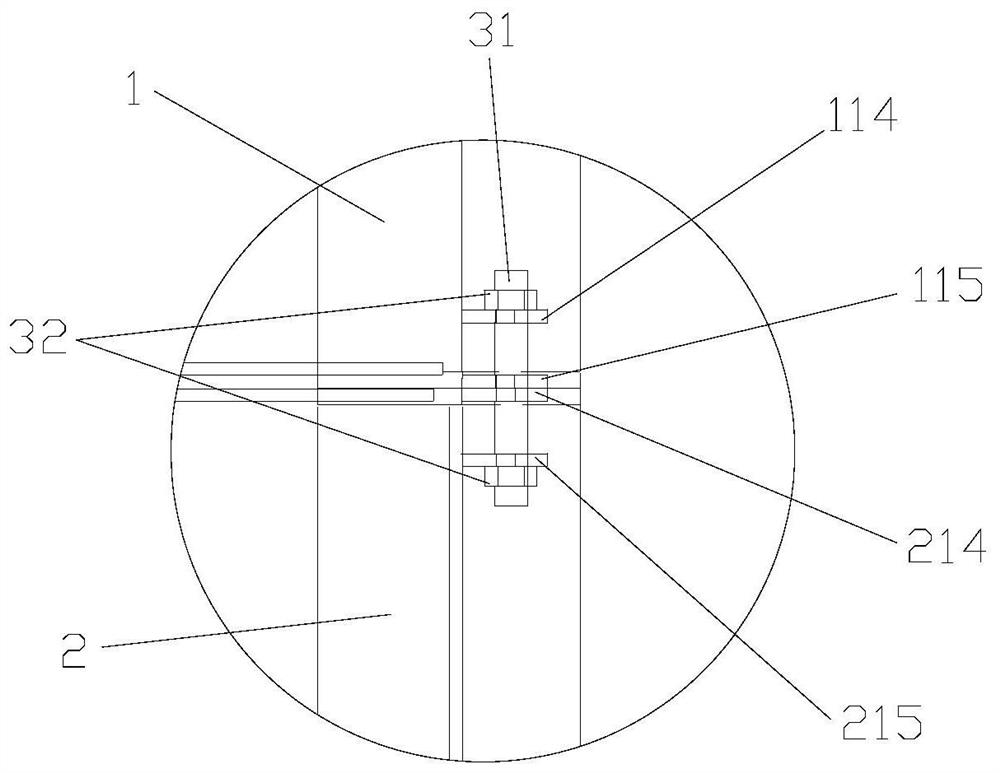

[0015] see Figure 1 to Figure 7 , the concrete drainpipe interface of the present invention is equipped with a sizing formwork for wiping tape construction, comprising a top form 1 and two side forms 2 .

[0016] The top mold 1 includes two top side plates 11, five top connecting rods 12 and two top rubber stopper strips 13; wherein,

[0017] The two top side panels 11 are arranged symmetrically on both sides of the interface of the concrete drain pipe, and the distance between the two top side panels 11 is equal to the width of the wiping belt, 15cm-20cm; the cross section of each top side panel 11 is Z-shaped and includes a semicircular arc Shaped top inner ring plate 111 and top outer ring plate 112 and the top radial plate 113 connected between the inner end of the top inner ring plate 11 and the outer end of the top outer ring plate 112; the inner diameter of the top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com