Novel magnetic active sealing butterfly valve

A technology of active sealing and active valve, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of poor sealing performance, short service life, and large wear of valve seat and sealing ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

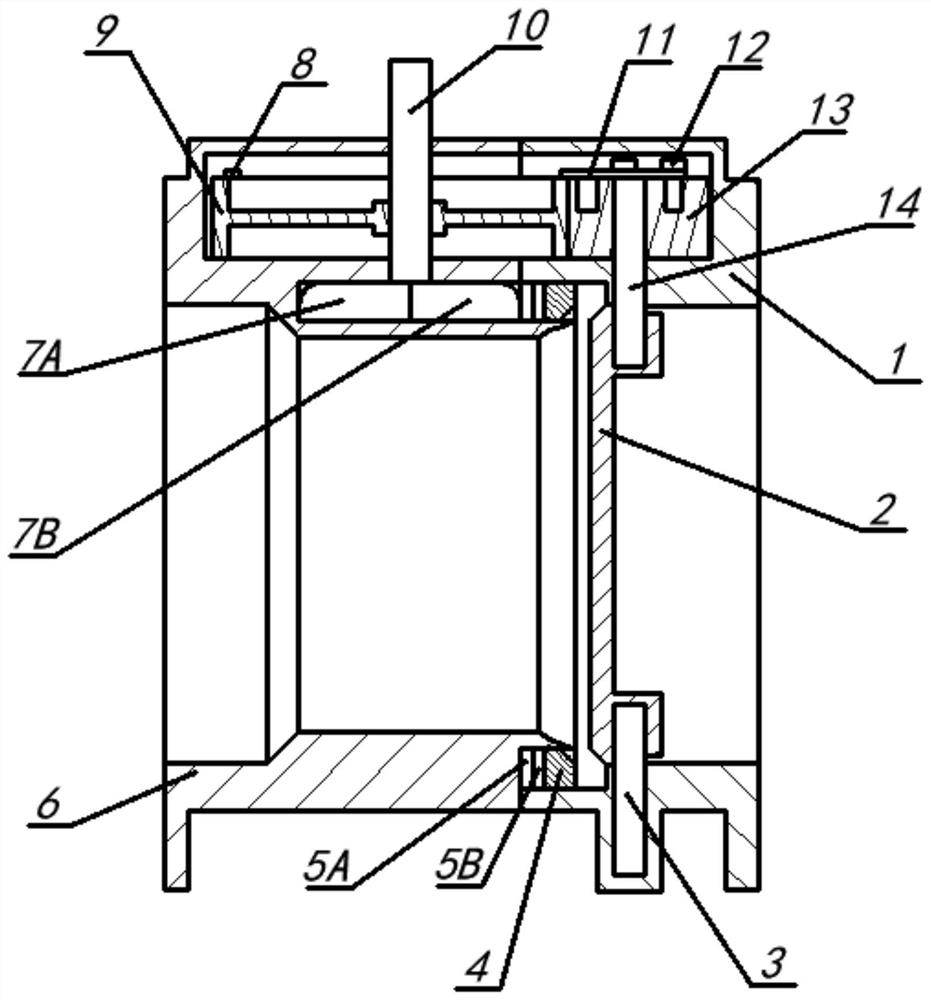

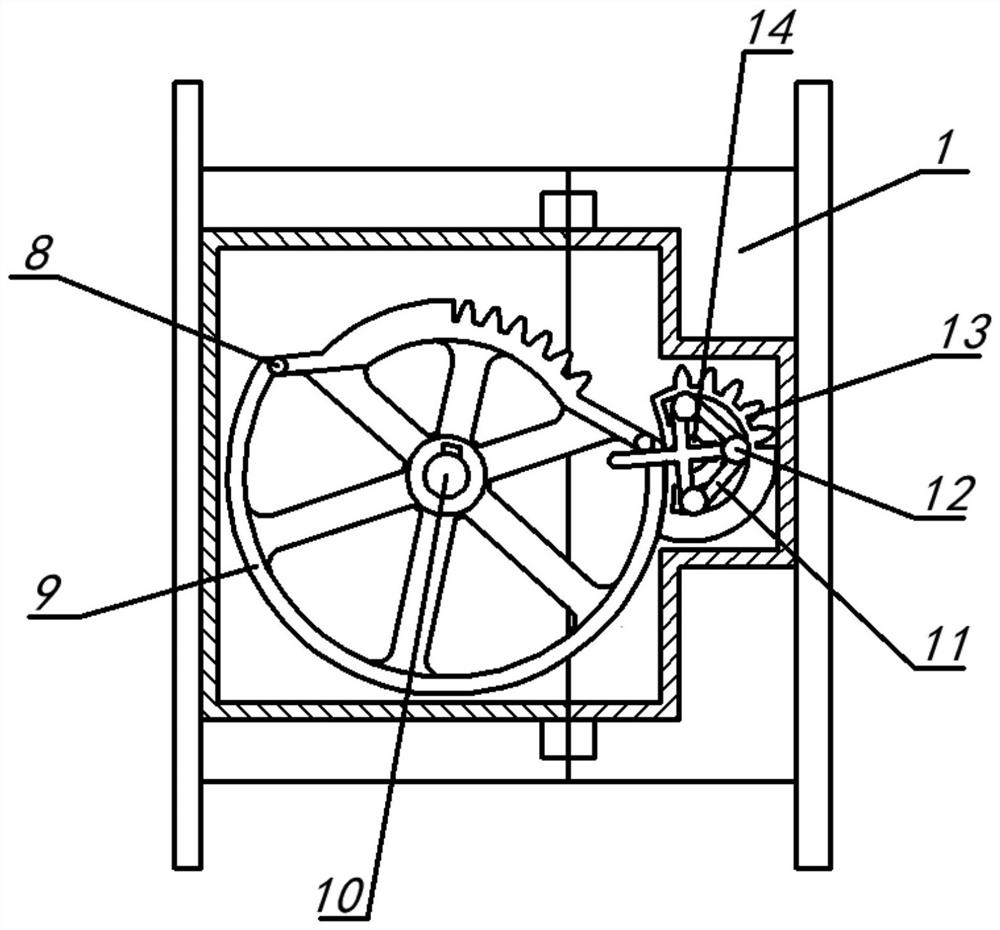

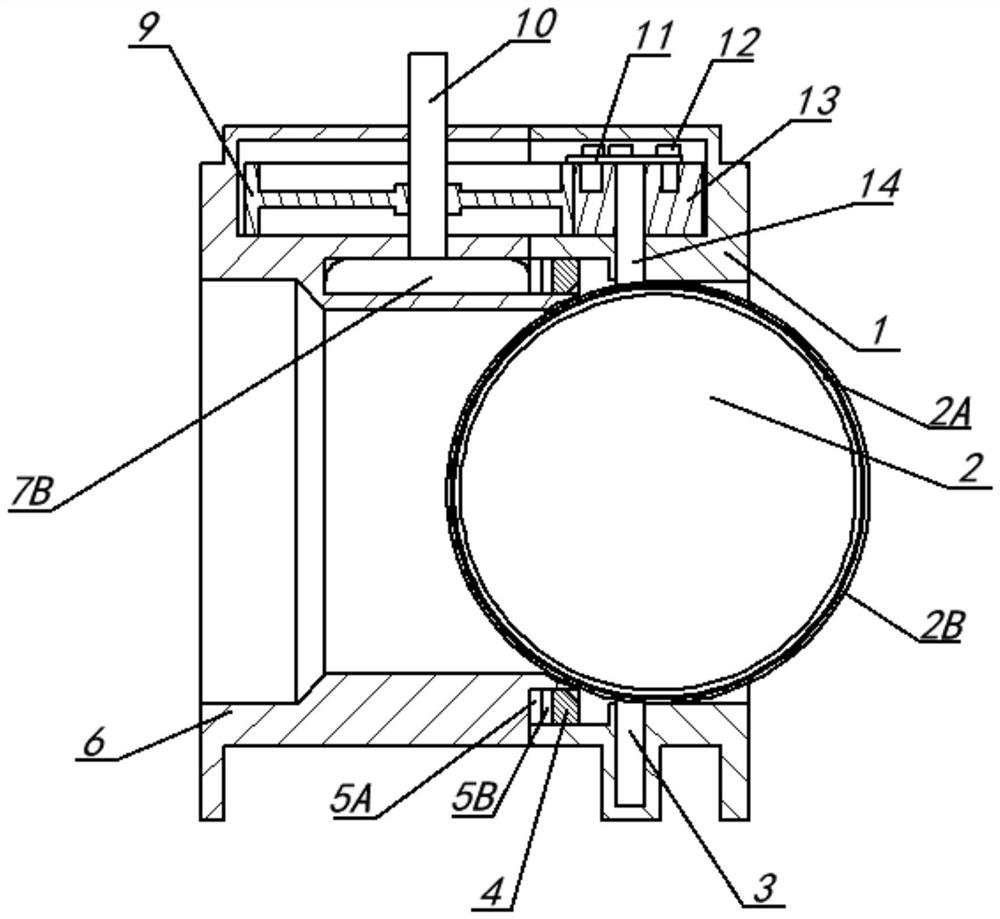

[0036] The specific implementation of the present invention will be described below in conjunction with the drawings and examples.

[0037] Such as figure 1 and figure 2As shown, including right valve body 1, valve plate 2, lower driven valve stem 3, valve seat 4, driven magnet 5, left valve body 6, driving magnet 7, driving gear 9, driving valve stem 10, driven gear 13 and the upper driven valve rod 14; the fluid flows along the direction from the left valve body 6 to the right valve body 1; The lower part of the inside of the right valve body 1 is provided with a flow path chamber for flow, which constitutes the valve chamber of the valve. The inside of the left valve body 6 and the right valve body 1 are all provided with a flow chamber for fluid communication. The left valve body 6 and the right valve body 1 The circulation cavity is just butted and matched; the left valve body 6 and the right valve body 1 above the valve cavity are provided with holes to form the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com