Punching die head connecting device convenient to replace

A technology of a connecting device and a stamping die, which is applied in the field of stamping and forming dies, can solve the problems of increasing the wear of the connecting part between the stamping head and the stamping machine, increasing the movable gap between the stamping head and the stamping machine, and reducing the movement accuracy of the stamping head, etc., so as to increase the work. Efficiency, increased concentricity, convenient and fast positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

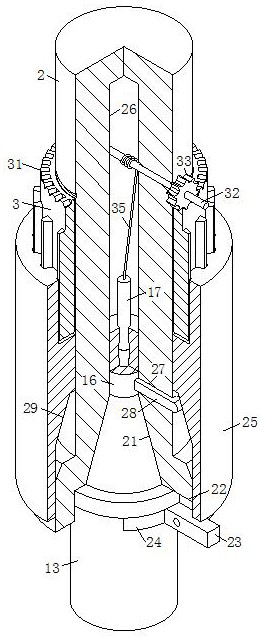

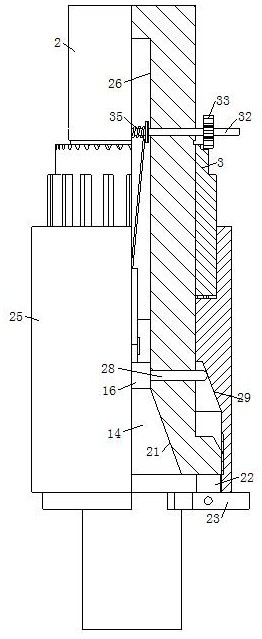

[0023] As an embodiment of the present invention, the bottom of the tapered groove 21 is provided with a No. 1 hole 26, and the top of the head 14 is provided with a round platform 16 that matches the No. 1 hole 26; the inner wall of the No. 1 hole 26 corresponds to the position of the round platform 16. A group of chute 27 is evenly distributed on the circumference, and a slider 28 is slidably connected to the chute 27. The end of the slider 28 away from the round platform 16 extends to the outside of the chute 27; part 29, the tapered part 29 is used to squeeze the slide block 28 after the casing 25 moves down, further increasing the connection stability between the punching head 13 and the punching machine; when the head 14 is embedded in the tapered groove 21, the head 14 drives the round table 16 to be inserted into the No. 1 hole 26, and then when the sleeve 25 rotates and locks the pressing rod 23, the tapered part 29 in the sleeve 25 rotates and moves downward, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com