Efficient mechanical maintenance prizing equipment

A mechanical and efficient technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of mechanical prying influence, shaking, mechanical shedding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

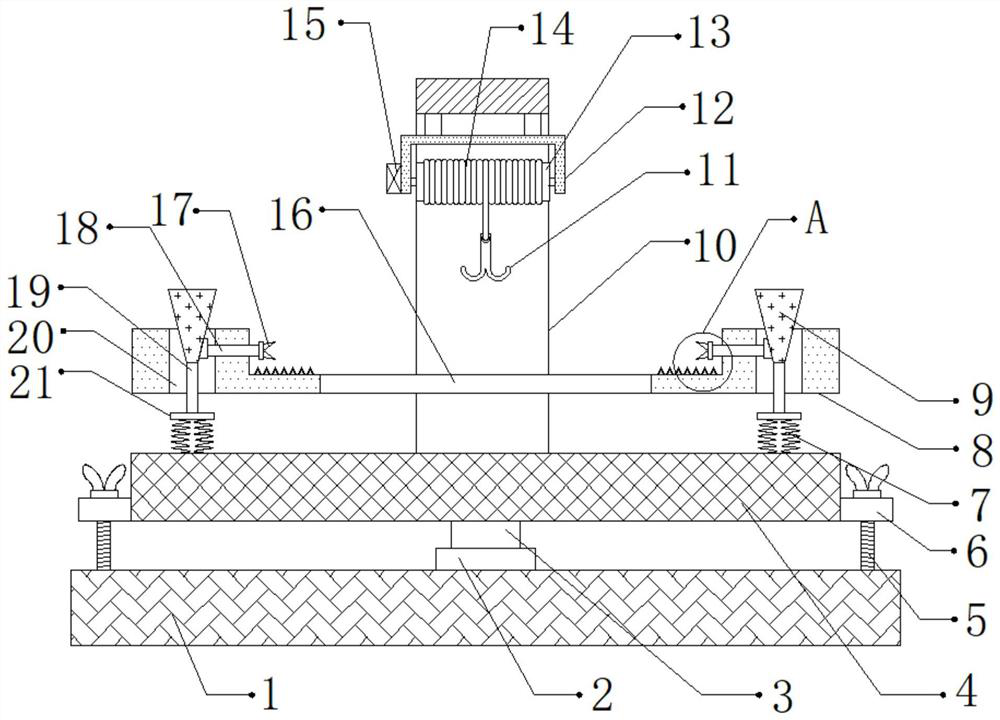

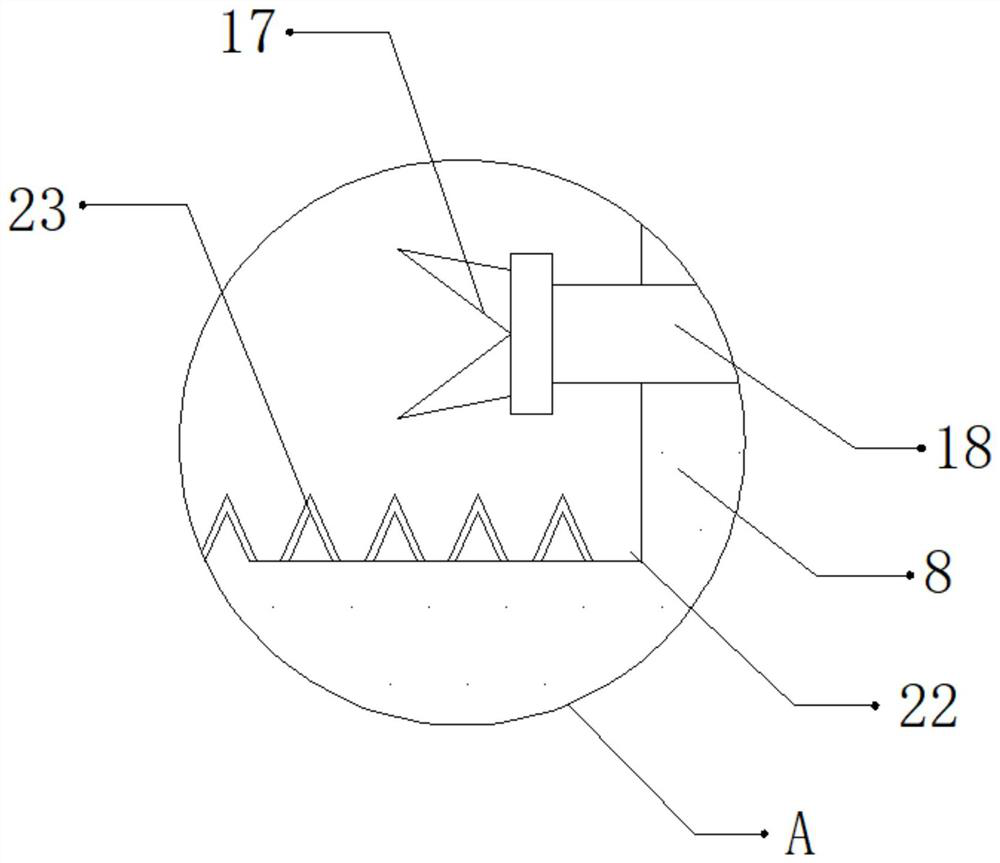

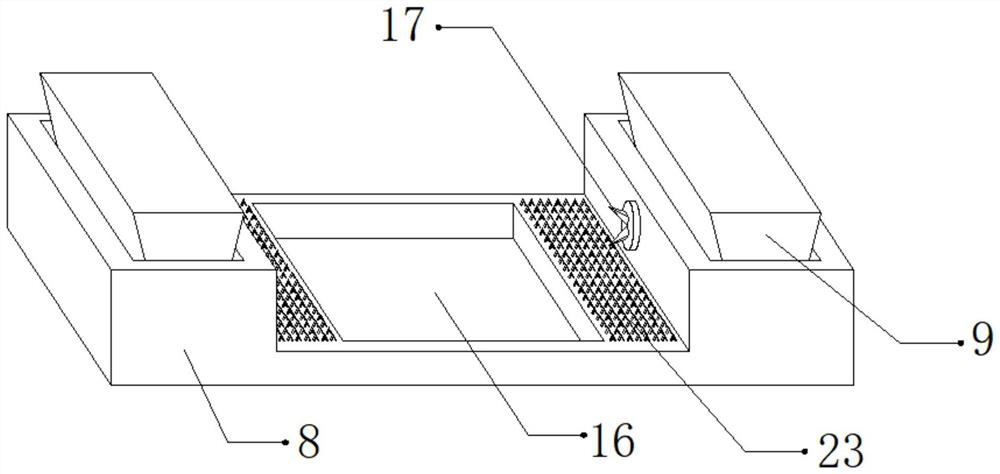

[0028] refer to Figure 1-3 , an efficient mechanical maintenance skid-mounted equipment, including a fixed seat 1 and a support plate 8, the top outer wall of the fixed seat 1 is connected with a damping bearing 2 through bolts, and the inner wall of the damping bearing 2 is rotatably connected with a rotating shaft 3, and the top outer wall of the rotating shaft 3 The fixing plate 4 is connected by bolts, and both sides of the top outer wall of the fixing plate 4 are connected with springs 7 by bolts. Rod 19, the top outer wall of the support rod 19 is connected with a connecting block 9 by bolts, and the cross section of the connecting block 9 is a trapezoid, and both sides of the top outer wall of the support plate 8 are provided with through holes 20, and the connecting block 9 is located in the through hole 20. Inside, one side of the inner wall of the two through holes 20 is provided with a socket, and the inner wall of the two sockets is inserted with a fixing rod 18, ...

Embodiment 2

[0038] refer to Figure 4 , a high-efficiency mechanical maintenance skid-mounted equipment. Compared with the first embodiment, the outer wall of one side of the fixing frame 10 is provided with a ventilation opening, and the inner wall of the ventilation opening is connected with a fan 24 by bolts, which can prevent the adhesion of mechanical The dust and debris on the machine are treated to prevent the dust and debris from adhering to the surface of the machine and causing interference to the maintenance of the machine.

[0039] Working principle: When in use, place the machinery that needs to be repaired and skid-mounted inside the U-shaped groove 22, preliminarily fix the machinery through the tooth block 17, start the motor 15, and the motor 15 will drive the hanging rope 14 and the hook 11 to carry out Move down to fix the top of the machine on the hook 11. After the fixing is completed, start the motor 15, and the motor 15 will drive the winding roller 13 to rotate, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com