Radial precompression tooling and method for metal rubber ball joint

A metal-rubber, pre-compression technology, used in punching machines, presses, manufacturing tools, etc., can solve the problems that the size requirements are difficult to meet the requirements, cannot be realized, and the molds are complex, and achieve simple and efficient radial pre-compression. Accuracy and reliability, the effect of reducing mold manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

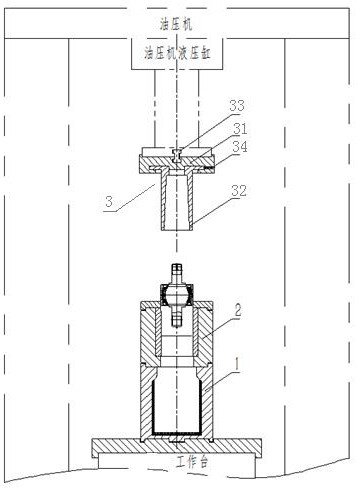

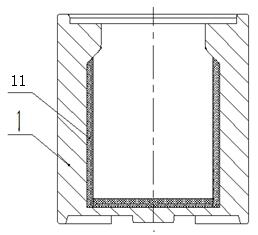

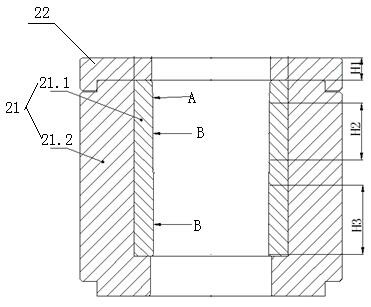

[0041] Combine below Figure 1 to Figure 8 The embodiments of the present invention will be described in detail.

[0042] The metal rubber ball joint radial precompression tooling includes a base 1 positioned on a horizontal workbench, the base 1 is a cylindrical structure with an upward opening, and is characterized in that it also includes an extruder for radially pressing the metal rubber ball joint. The pressing cylinder assembly 2 and the pressing head assembly 3 for pressing down the metal-rubber ball joint, the pressing cylinder assembly 2 is coaxially placed on the base 1, and the pressing head assembly 3 is coaxially arranged directly above the extrusion cylinder assembly 2 , and hoisted on the hydraulic cylinder of the oil press, the metal rubber ball joint is vertically supported on the extrusion cylinder assembly 2, and is pressed down with the pressure head assembly 3, and then falls into the base 1 after being radially extruded by the extrusion cylinder assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com