A constant pressure stable heat transfer method for a manual heat press machine for flexible materials

A technology of flexible materials and heat press machines, applied in the fields of machines for branding, crafts for producing decorative surface effects, decorative arts, etc., can solve the problems of low pressure, uneven pressure of heat press, high pressure, etc., to achieve The effect of heat transfer is high quality, easy to promote and use, and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

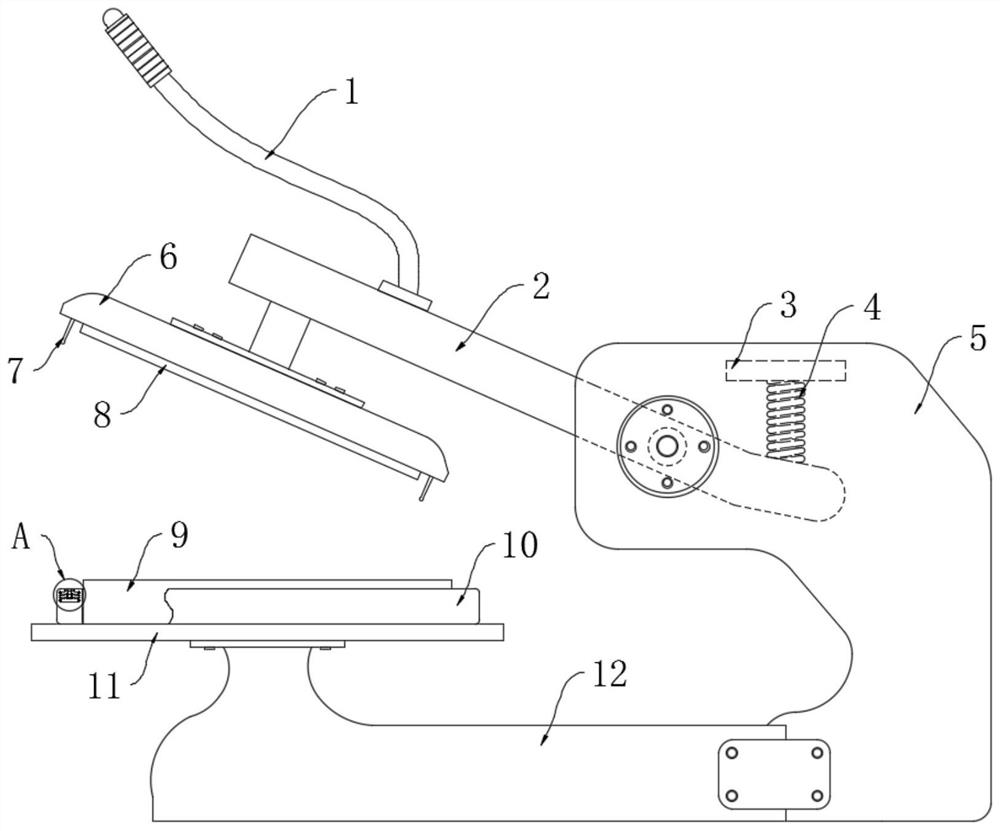

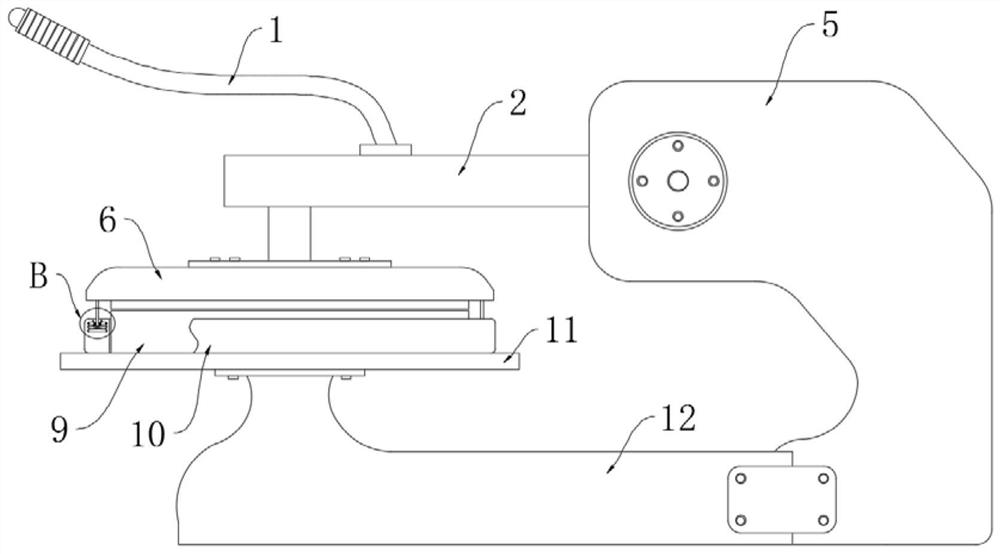

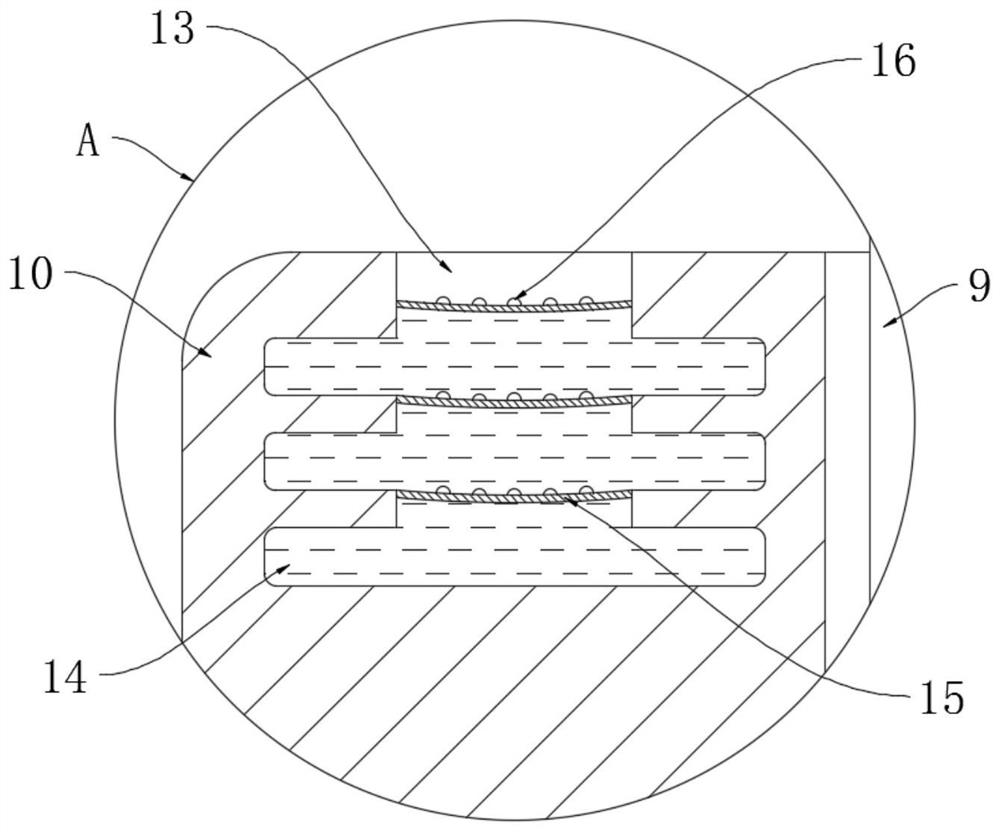

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0027] refer to Figure 1-5 , a constant pressure stable heat transfer method for a manual heat transfer machine for flexible materials, the specific heat transfer method is as follows:

[0028] S1. Preheating the heating plate 8: turn on the power, set the current size, and make the heating plate 8 energized to generate heat until the overall temperature of the heating plate 8 rises to the temperature required for heat transfer;

[0029] S2. Lay the ironing piece: Lay the ironing piece on the lower plate 9, and then place the heat transfer paper facing down on the corresponding position of the ironing piece. If transfer paper is used, first pass the pattern to be ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com