Device and method for measuring and adjusting roundness of shell wall of hot blast stove

A technology for hot blast stoves and furnace shells, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., which can solve the problems of thick and heavy hot blast stove shells and difficult roundness control, so as to reduce potential safety hazards, ensure effectiveness, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

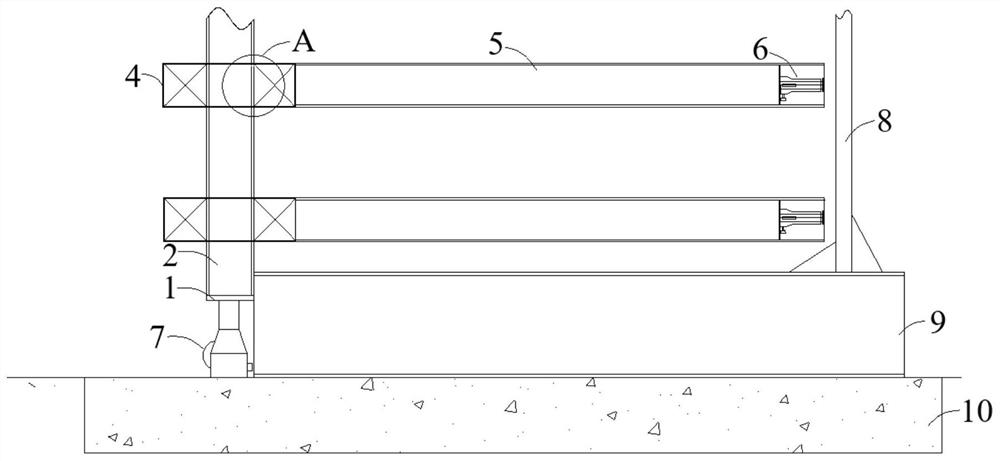

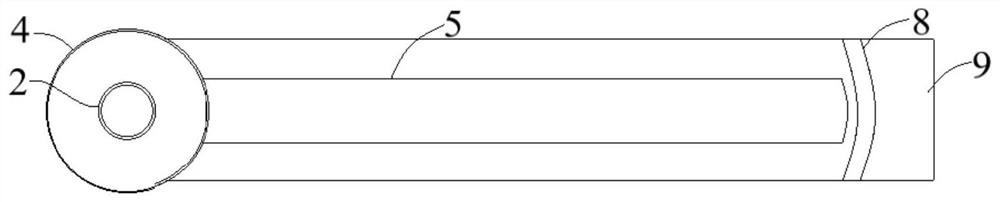

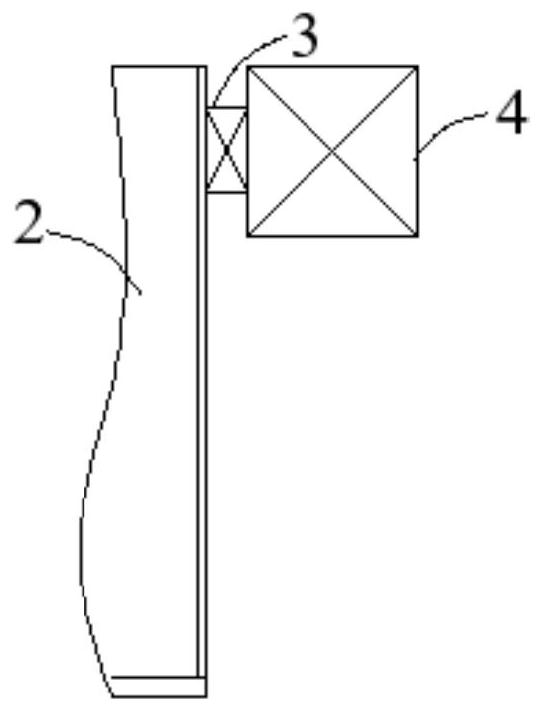

[0034] combine figure 1 with figure 2 , A device for measuring and adjusting the roundness of the shell wall of a hot blast stove in this embodiment includes a backing plate 1, an inner column support 2, a bearing 3, a steel sleeve 4, a correction mechanism, a jacking mechanism and a pair of molds 9. The jacking mechanism uses a vertical jack 7, the vertical jack 7 is fixed on the ground, its jacking end is fixed on one side of the backing plate 1, and the bottom end of the inner column support 2 is welded on the backing plate 1. In this embodiment, the inner Column support 2 is made of DN80 steel pipe. The inner column support 2 can move in the vertical direction under the jacking action of the vertical jack 7 .

[0035] The pair of tires 9 includes 12 support pads, the 12 support pads are arranged radially with the inner column support 2 as the center of circle, and each support pad is provided with 2 blocks; during construction, The furnace shell 8 is hoisted to the pai...

Embodiment 2

[0040] A method for measuring and adjusting the roundness of the shell wall of a hot blast stove in this embodiment uses the measuring and adjusting device described in Embodiment 1, and the steps are:

[0041] Step 1. Measure the center point of the shell 8 for setting out the wires, install the vertical jack 7 and the backing plate 1 on the center point, and level the two; weld the inner column support 2 vertically on the backing plate 1, and Adjust its verticality; ensure that the center points at different heights are consistent, so as to ensure the reliability of the calibration circle.

[0042] Install the correcting mechanism so that the length of the arc correcting beam 5 is 20mm shorter than the diameter of the furnace shell 8 to be measured and adjusted, so as to prevent the furnace shell 8 from being unable to rotate in the deformed area;

[0043] Set up a pair of molds 9 around the inner column support 2, and set two stoppers on it according to the diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com