Light-water-coaxial laser shock peening device

A laser shock hardening, coaxial technology, applied in the field of laser shock hardening processing, can solve the problem that the laser shock hardening device is difficult to apply surface impact hardening and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

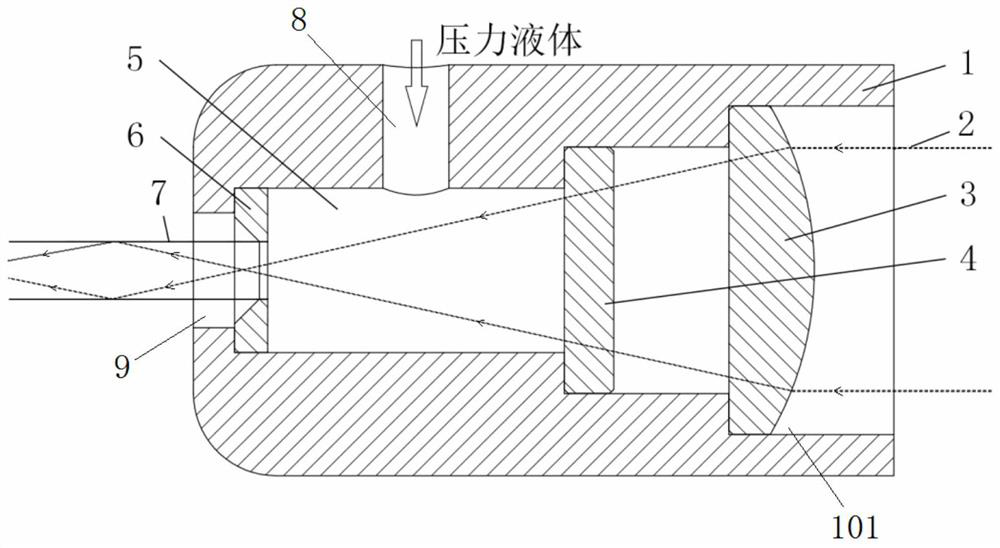

[0023] Such as figure 1 As shown, the present invention includes a housing 1, a laser focusing lens 3, a laser window 4 and a nozzle 6, a hydraulic equalization chamber 5 is provided in the housing 1, and a laser window 4 is provided on one side of the hydraulic equalization chamber 5 , the other side is provided with a nozzle 6, a laser focusing lens 3 is located in the housing 1 and outside the laser window 4, the rear end of the housing 1 is provided with an opening and the laser light 2 emitted by the pulse laser is emitted by the housing 1 After being injected into the rear end opening, the liquid in the laser focusing lens 3, the laser window 4 and the hydraulic equalization chamber 5 is irradiated in the nozzle 6, and the housing 1 is provided with an interface 8 and the liquid The hydraulic equalization chamber 5 communicates with each other, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com