Air release valve and compressor air release control system using it, aero-engine

A technology of bleed valve and air compressor, which is applied in the direction of machines/engines, pump control, gas turbine devices, etc. It can solve the problems of large oil pressure control pipeline layout space, inability to meet the needs of engine electronic control, and shape interference, etc., to achieve Meet the requirements of electronic control, realize the miniaturization design, and the effect of flexible deflation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

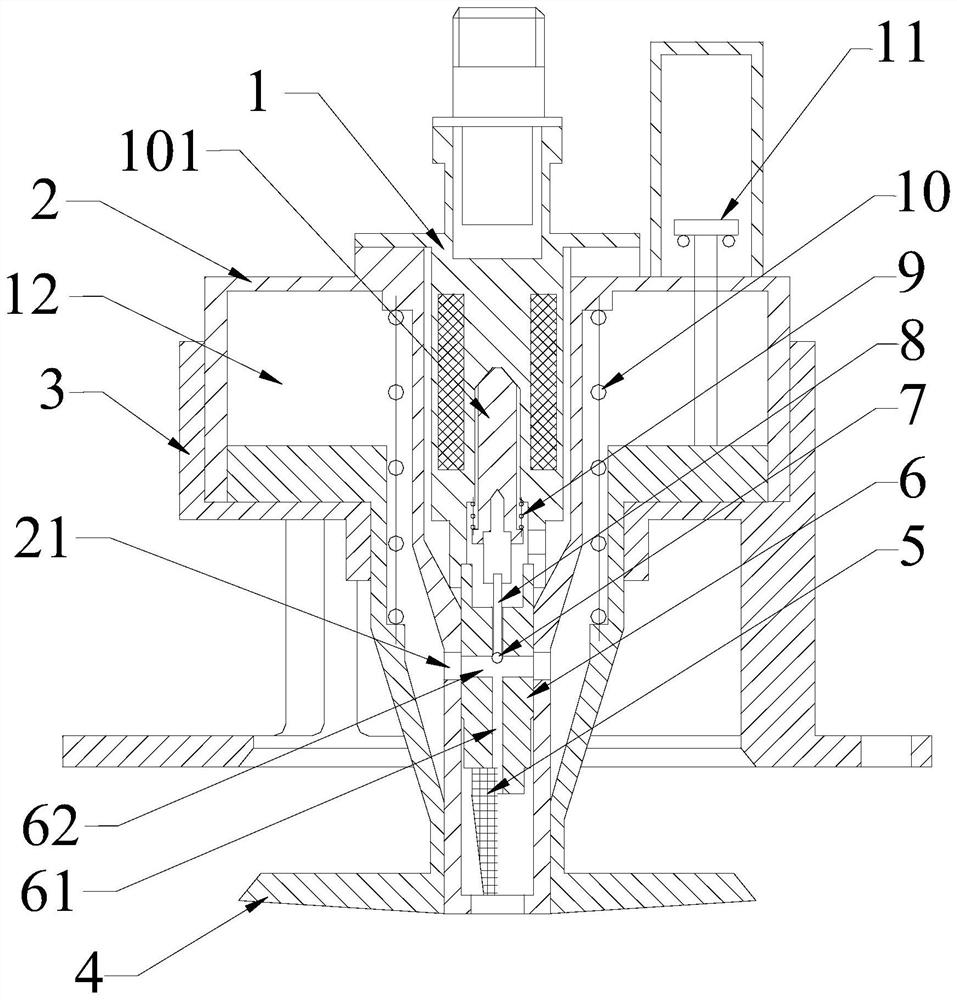

[0040] Such as Figure 3 to Figure 5 As shown, the first embodiment of the present invention provides a deflation valve, which is used to be installed on the air collection chamber of any stage of the compressor for deflation, and the deflation valve includes an electromagnet assembly 1, an upper casing 2 , base 3, valve 4, guide sleeve 6, steel ball 7, ejector rod 8, iron core spring 9 and valve spring 10, the base 3 is fixedly installed on the gas collection chamber of the compressor, specifically, the base 3 There are 8 installation holes on the top, and it is fixed on the installation side of the air collection chamber valve by 8 screws. The upper casing 2 is fixedly mounted on the base 3 by screws, the valve 4 is installed between the base 3 and the upper ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com