Performance testing device and measuring method for oil inlet metering valve of common rail pump

A technology of oil inlet metering valve and testing device, which is applied in the field of common rail pumps and can solve problems such as inaccurate measurement and misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

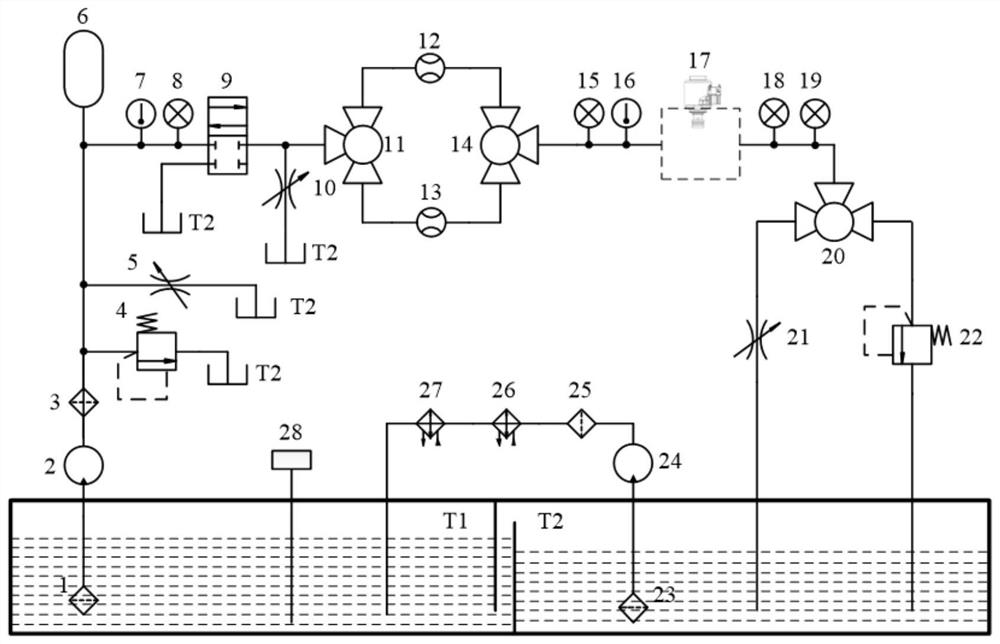

[0062] as attached Figure 1-11 As shown, a common rail pump oil inlet metering valve performance test device includes a first oil tank T1 and a second oil tank T2 filled with ISO 4113 standard calibration oil. The gear type oil pump 24 sucks oil from the second oil tank T2, and passes through The first coarse filter 23 of 200 μm, the first fine filter 25 of 10 μm, the first heat exchanger 26 and the second heat exchanger 27 are sent in the first oil tank T1;

[0063] The plunger type oil pump 2 sucks oil from the first oil tank T1, and sends it to the P port of the proportional servo valve 9 through the second coarse filter 1 of 200 μm and the second fine filter 3 of 5 μm. The motor 37 is driven, and its speed is regulated by the industrial computer 31 through the communication between the RS-485 communication port 35 and the frequency converter 36; the outlet pressure of the plunger oil pump 2 is regulated by the first throttle valve 5 and stabilized by the accumulator 6 ; ...

Embodiment 2

[0079] The method for measuring the current-flow characteristics of the oil inlet metering valve based on the test device described in Embodiment 1:

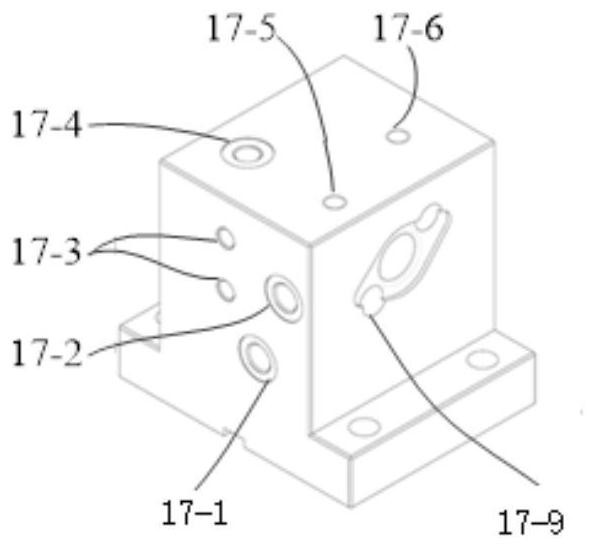

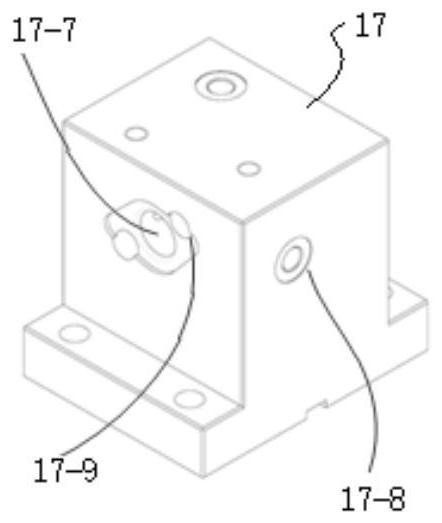

[0080] Step 1. Insert the measured oil metering valve into the first installation port 17-7 of the valve block 17, switch the first pneumatic three-way ball valve 11 and the second pneumatic three-way ball valve 14 to form a passage with the gear flowmeter 12, The connection between the first pneumatic three-way ball valve 11, the second pneumatic three-way ball valve 14 and the piston flowmeter 13 is closed; the third pneumatic three-way ball valve 20 communicates with the second oil tank T2 through the second overflow valve 22; The third pneumatic three-way ball valve 20 is closed through the second throttle valve 21 and the second oil tank T2; Then the piston rod of the second cylinder 29 pushes the spring probe to contact the socket pin of the oil inlet metering valve; The outlet pressure of the plug oil pump 2 is 70 bar, t...

Embodiment 3

[0089] Based on the measurement method of the test device described in embodiment one to the opening and closing delay time of the oil inlet metering valve:

[0090] Step 1 is the same as Step 1 in Embodiment 2, and will not be repeated here.

[0091] Step 2. Manually adjust the proportional servo valve 9 and the second throttle valve 21 so that the inlet pressure of the oil inlet metering valve is 6±0.05 bar, and the outlet pressure of the oil inlet metering valve is 5.5±0.05 bar, which is the measured value of the inlet pressure sensor 15 is 6±0.05bar, and the measured value of the second outlet pressure sensor 19 is 5.5±0.05bar; when the inlet pressure and outlet pressure of the oil inlet metering valve are within the above range for more than 0.5s, the pressure is considered to be stable;

[0092] Step 3, then follow the Figure 10 or Figure 11 According to the PWM duty ratio change method, the analog voltage output channel AO0 of the first data acquisition card 32 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com