Dynamic truck scale and truck scale system

A truck scale and dynamic technology, which is applied in the field of dynamic truck scales and truck scale systems, can solve the problems of poor economy and practicability of truck scales and poor limit stability of weighing platform, so as to reduce overall processing and manufacturing costs and improve work efficiency. The effect of stability and improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

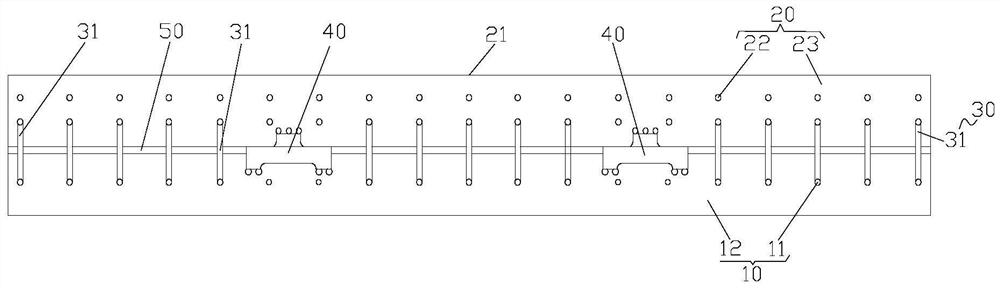

[0033] Such as image 3 As shown, in order to ensure that the support structure layer 10 and the limiting structure 30 provide sufficient pulling force to the load-bearing structure layer 20, and make the stress points of the load-bearing structure layer 20 evenly distributed in its extension plane to avoid the load-bearing structure layer 20 being subjected to For stress concentration, there are multiple limiting structures 30 , and the multiple limiting structures 30 are distributed between the support structure layer 10 and the bearing structure layer 20 at intervals in the transverse plane.

[0034] Such as image 3 As shown, in this embodiment, the limiting structure 30 extends longitudinally, which facilitates the manufacturing cost of the dynamic truck scale and improves the economy of the dynamic truck scale.

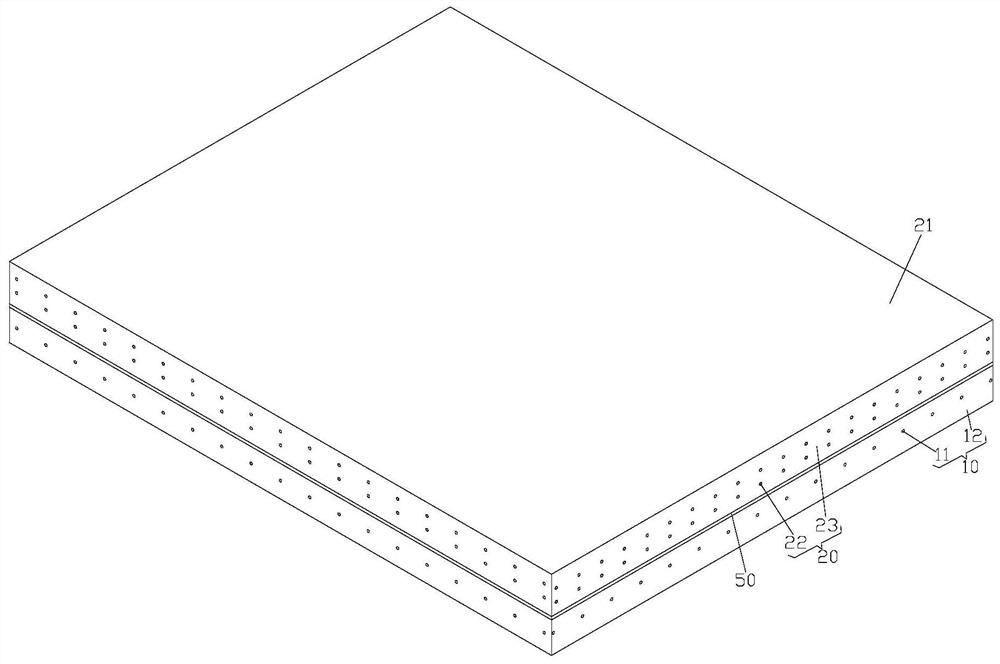

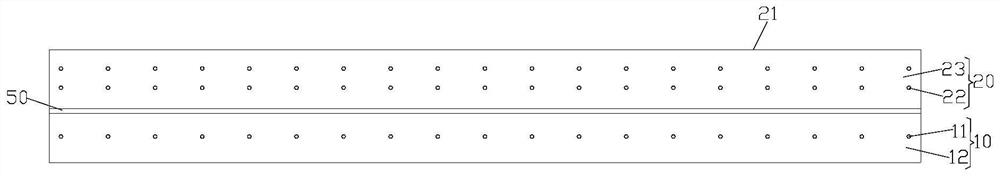

[0035]In the embodiment of the dynamic truck scale of the present application, the support structure layer 10 includes a first support network structure 11 and...

Embodiment 2

[0043] Such as Figure 4 As shown, the difference between this embodiment and the first embodiment lies in the different setting positions of the limiting structures 30 , specifically, the two ends of each limiting structure 30 are respectively connected to the end surface of the bearing structure layer 20 and the supporting structure layer 10 . That is to say, the limiting structures 30 are distributed around the circumferential direction of the dynamic truck scale at intervals, thus further reducing the manufacturing difficulty of the dynamic truck scale. Of course, the limiting structure 30 can also be selectively arranged at both ends of the dynamic truck scale in the length direction or width direction.

[0044] In addition, if Figure 4 As shown, in order to further enhance the stability of the space-limiting structure 30 connecting the support structure layer 10 and the load-bearing structure layer 20, the space-limiting structure 30 also includes a concrete reinforcem...

Embodiment 3

[0047] Such as Figure 5 As shown, the difference between this embodiment and the first embodiment lies in the arrangement of the limiting structures 30 . Specifically, the limiting structures 30 are all inclined to one side of the driving direction when the vehicle passes the weighing bearing surface 21 . The limit structure 30 of this structural form can provide a greater lateral horizontal component force for the load-bearing structure layer 20, and the horizontal horizontal component force is opposite to the driving direction of the vehicle when it passes the weighing bearing surface 21, thus further effectively ensuring the support There is no relative displacement between the structural layer 10 and the load-bearing structural layer 20 .

[0048] Of course, in an unillustrated embodiment of the present application, there are multiple limiting structures 30, wherein a part of the limiting structures 30 is inclined to one side of the driving direction when the vehicle pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com