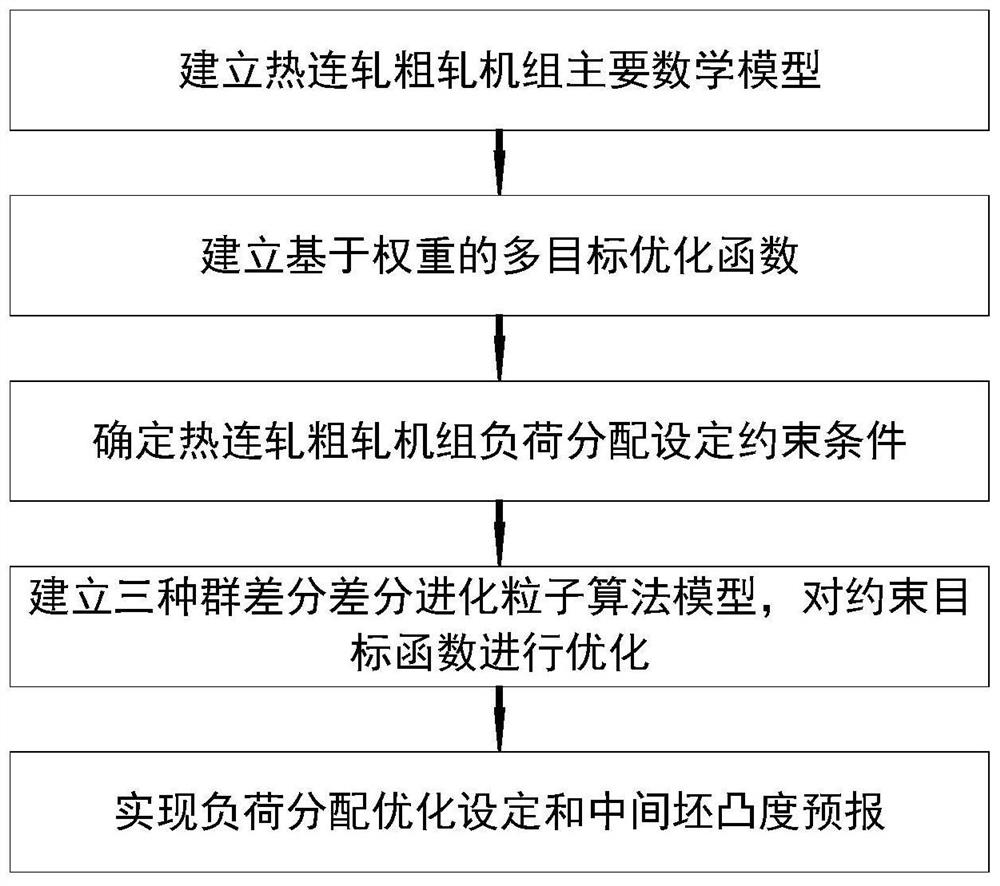

Hot rolling and rough rolling load distribution method considering convexity of intermediate billet

A technology of load distribution and rough rolling, applied in the field of control, can solve problems such as unreasonable distribution of finish rolling crown, failure to consider the optimization conditions of intermediate billet crown, and insufficient calculation speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

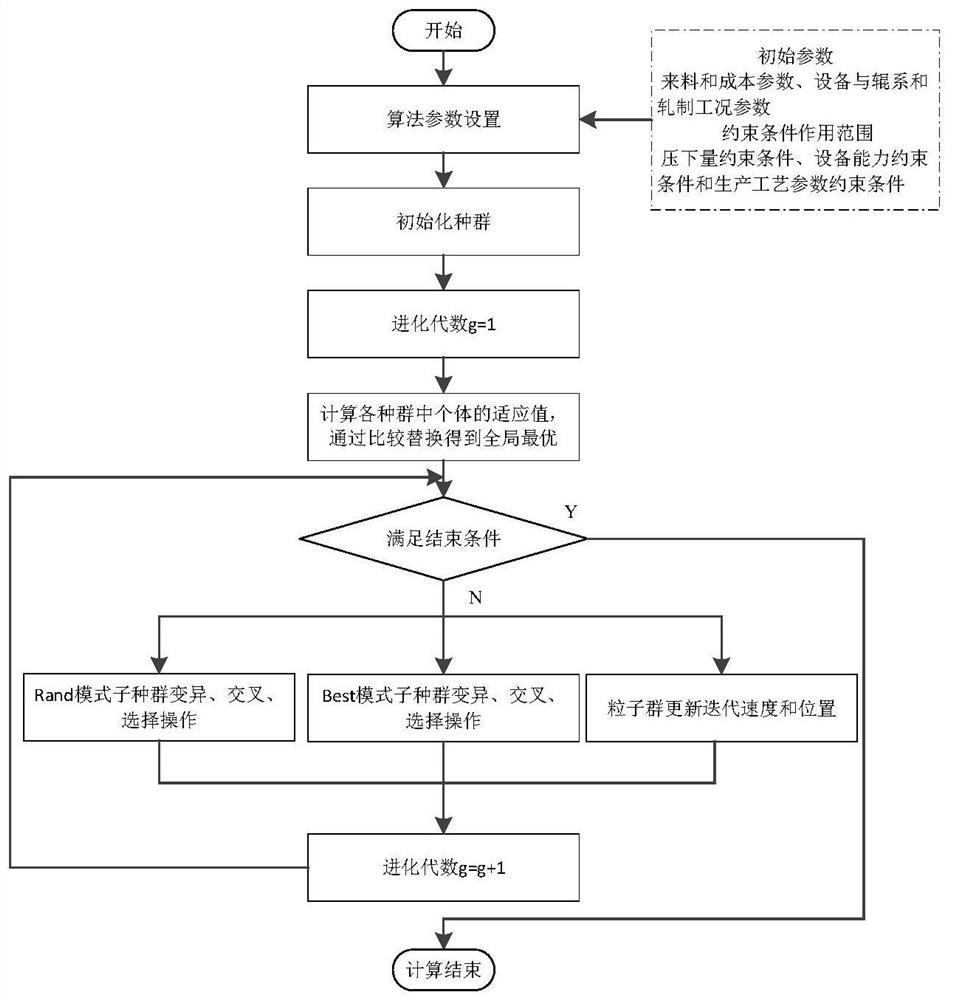

Method used

Image

Examples

Embodiment Construction

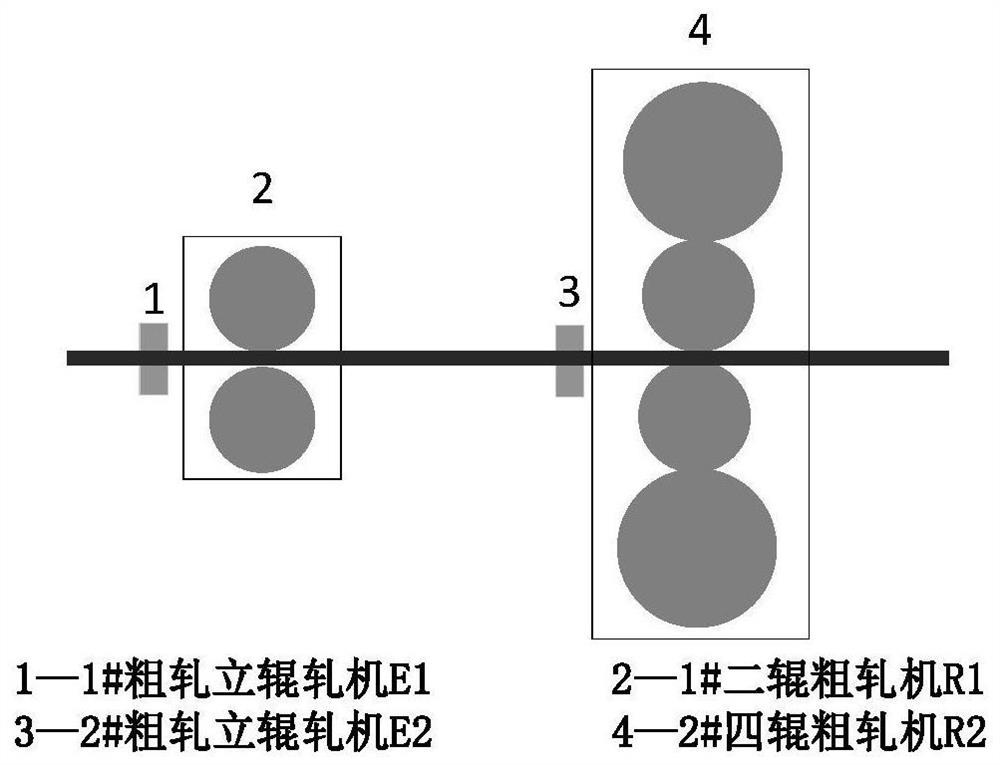

[0056] The following is a further description of the invention patent in combination with specific implementation cases. This implementation case is a hot continuous rolling rough rolling double-stand production line, and the layout is as follows image 3 As shown, the rough rolling R1 equipment parameters are shown in Table 1, and the rough rolling R2 equipment parameters are shown in Table 2.

[0057] Table 1 Rough rolling R1 equipment parameters

[0058]

[0059] Table 2-2 Rough rolling R2 equipment parameters

[0060]

[0061]

[0062] A kind of hot rolling rough rolling load distribution method considering the crown of the intermediate billet, specifically comprising the following steps:

[0063] Step 1: The established rolling process characteristic parameter calculation model, including (1), (2) and (3):

[0064] (1) Rolling force model:

[0065] P=Bl c Q p KK T

[0066] Among them, P is the rolling force, KN; l c In order to consider the horizontal pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com