Intelligent rubber mixing system and method

A rubber mixing and intelligent technology, applied in the field of rubber machinery, can solve problems such as poor rubber mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

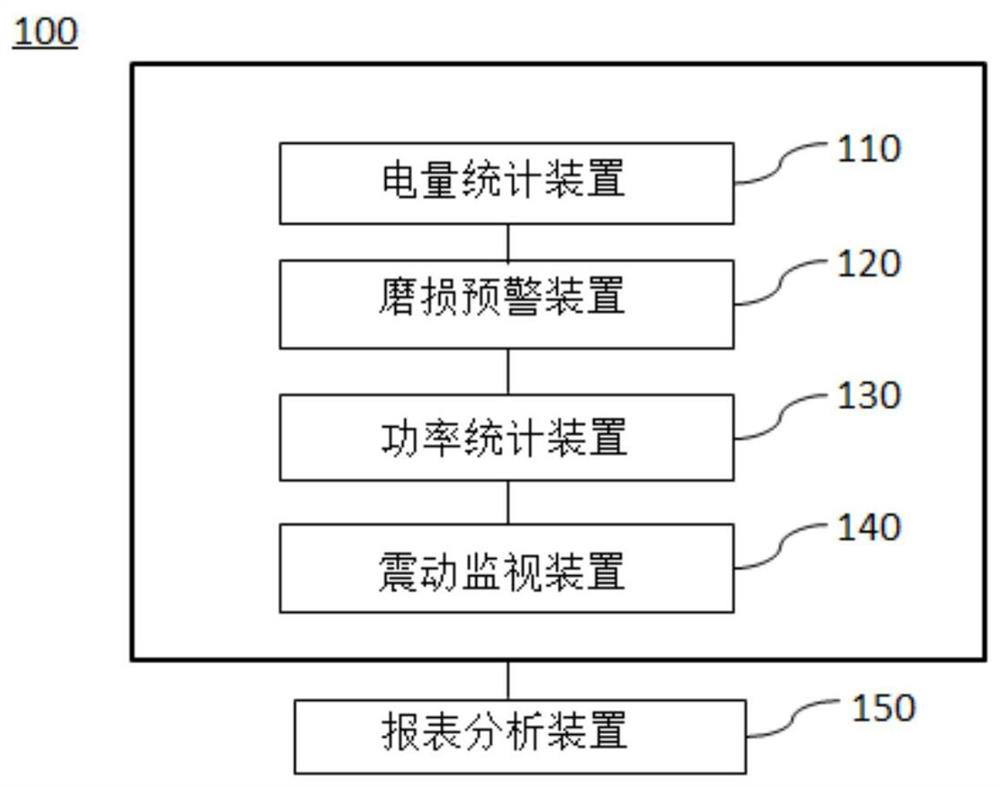

[0031] Please refer to figure 1 , figure 1 It is a schematic block diagram of the intelligent rubber mixing system provided by Embodiment 1 of the present invention.

[0032] In an embodiment, the intelligent rubber mixing system is applied to multiple rubber mixing machines (which can be regarded as internal mixers). Multiple rubber mixing machines in the department conduct individual machine evaluation, or evaluation of operators, evaluation of overall rubber raw material consumption, or evaluation of overall product output. The intelligent rubber mixing system 100 includes a power statistics device 110 , a wear warning device 120 , a power statistics device 130 , a vibration monitoring device 140 and a report analysis device 150 . The wear warning device 120 is electrically connected to the power statistics device 110 . The power statistics device 130 is electrically connected to the wear warning device 120 . The vibration monitoring device 140 is electrically connected...

Embodiment 2

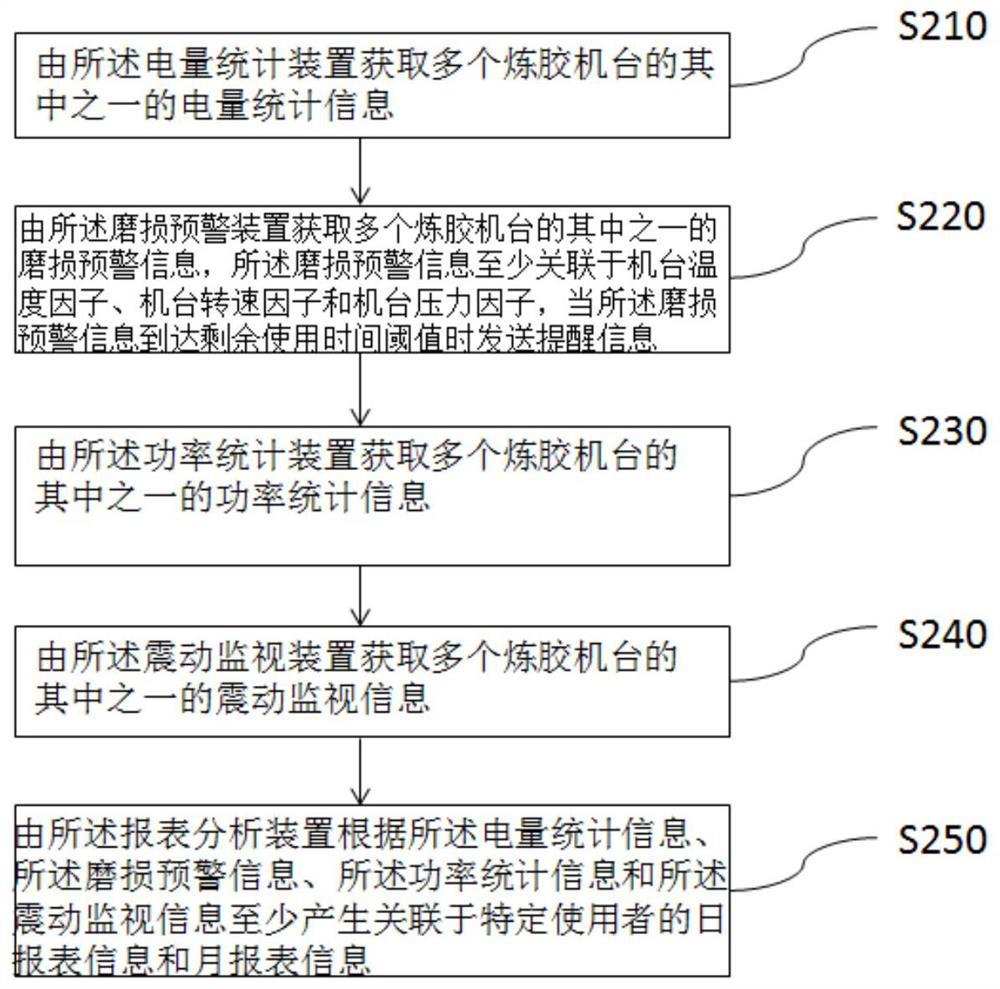

[0042] see figure 2 , figure 2 It is a method flowchart of the intelligent rubber mixing method provided by Embodiment 2 of the present invention. An intelligent rubber mixing method, the intelligent rubber mixing method is applied to an intelligent rubber mixing system, and the intelligent rubber mixing system is applied to multiple rubber mixing machines, and the intelligent rubber mixing system includes a power statistics device and a wear warning device , a power statistics device, a vibration monitoring device and a report analysis device, the wear warning device is electrically connected to the power statistics device, the power statistics device is electrically connected to the wear warning device, and the vibration monitoring device is connected to the The power statistics device is electrically connected, the statement analysis device is connected in communication with the power statistics device, the wear warning device, the power statistics device and the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com