electrical connector combination

An electrical connector and connector technology, applied in the direction of connection, current collector, rotary current collector, etc., can solve the problems of unstable contact and poor contact, and achieve the effect of facilitating disassembly, easy manufacturing, and avoiding unstable contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

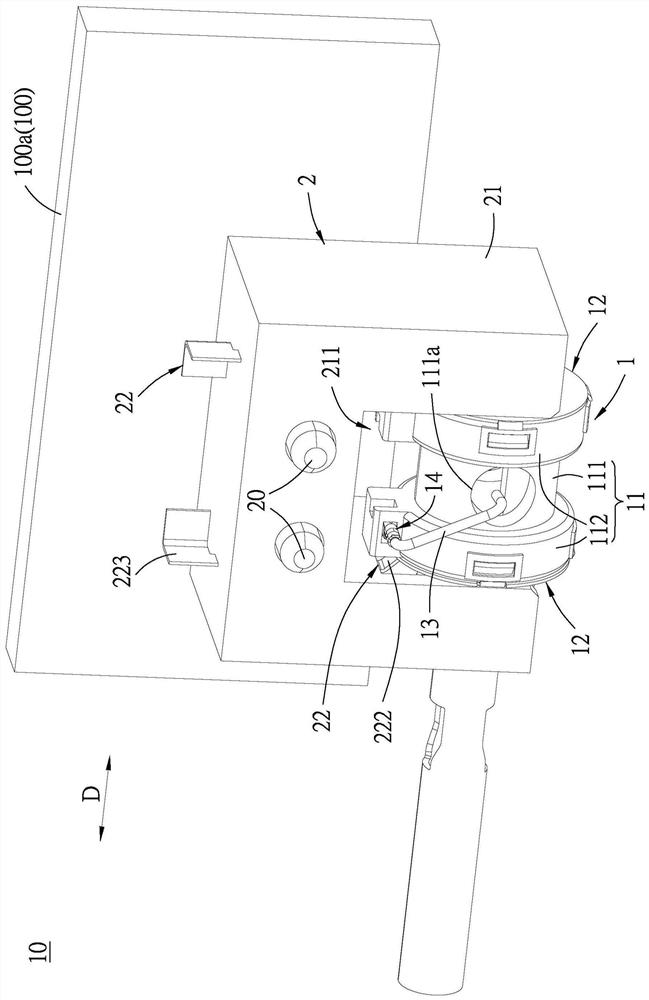

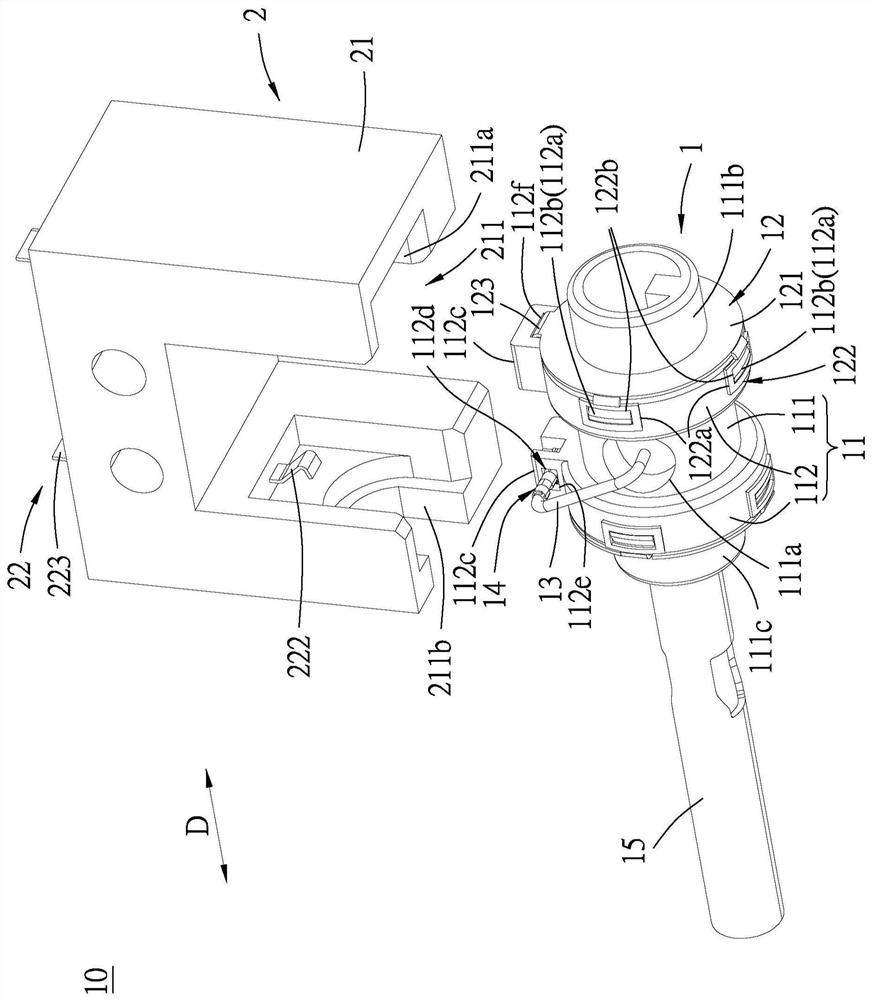

[0068] refer to Figure 1 to Figure 2 , an embodiment of the electrical connector assembly 10 of the present invention includes a first connector 1 and a second connector 2 .

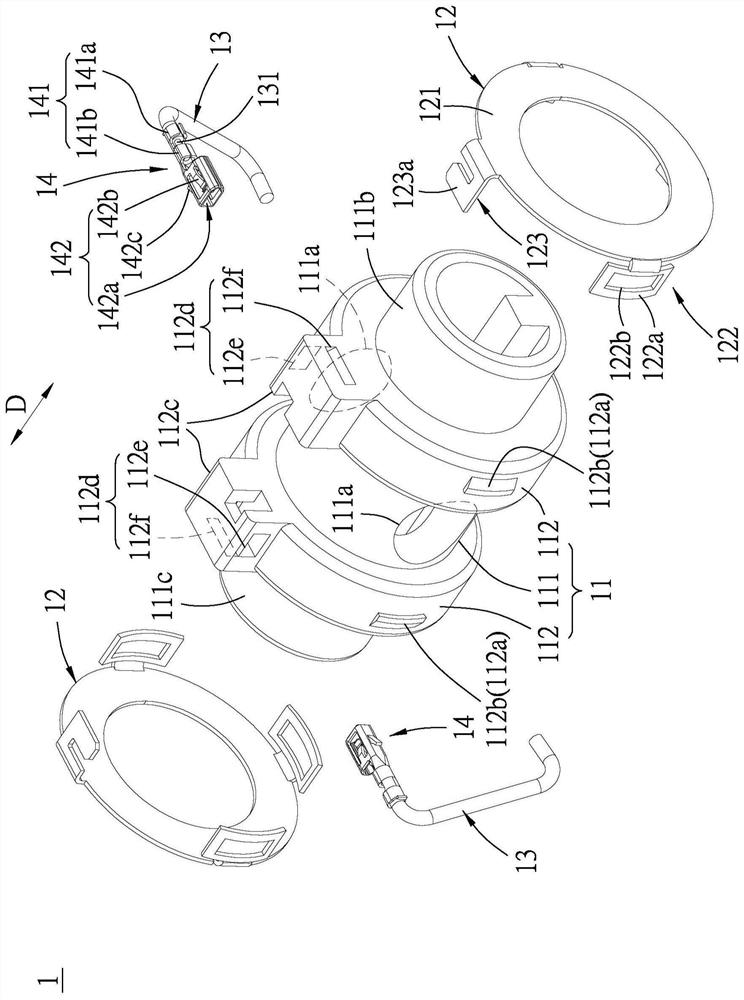

[0069] refer to Figure 2 to Figure 5 , the first connector 1 includes a rotating shaft 11 , two conductive rings 12 , two wires 13 , two connection terminals 14 , and an inner sleeve 15 . The rotating shaft 11 is, for example, made of insulating material such as plastic and includes a tube body 111 extending in an axial direction D, and an annular protrusion 112 formed on the outer peripheral surface of the tube body 111 . A plurality of conductive rings 12 are spaced apart from each other on the annular protrusion 112, and each conductive ring 12 has a contact ring surface 121 facing the axial direction D. In this embodiment, the annular protrusion The number of 112 is two, and two annular protrusions 112 are formed on the tube body 111 at intervals from each other, and two conductive rings 12 are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com