Adhesive spreading mechanism based on special textile fabric coating device

A special technology for textile fabrics, which is applied to the device and coating of the surface coating liquid, which can solve the problems of scraper edge bumps, poor structure, and the inability to realize automatic locking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

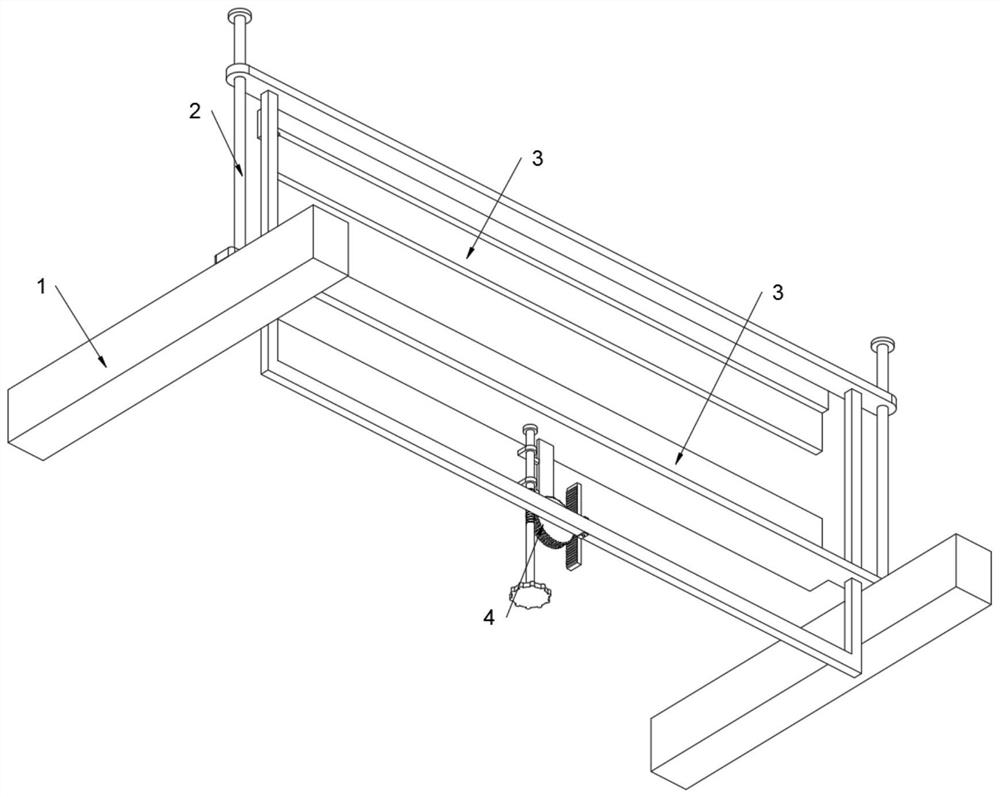

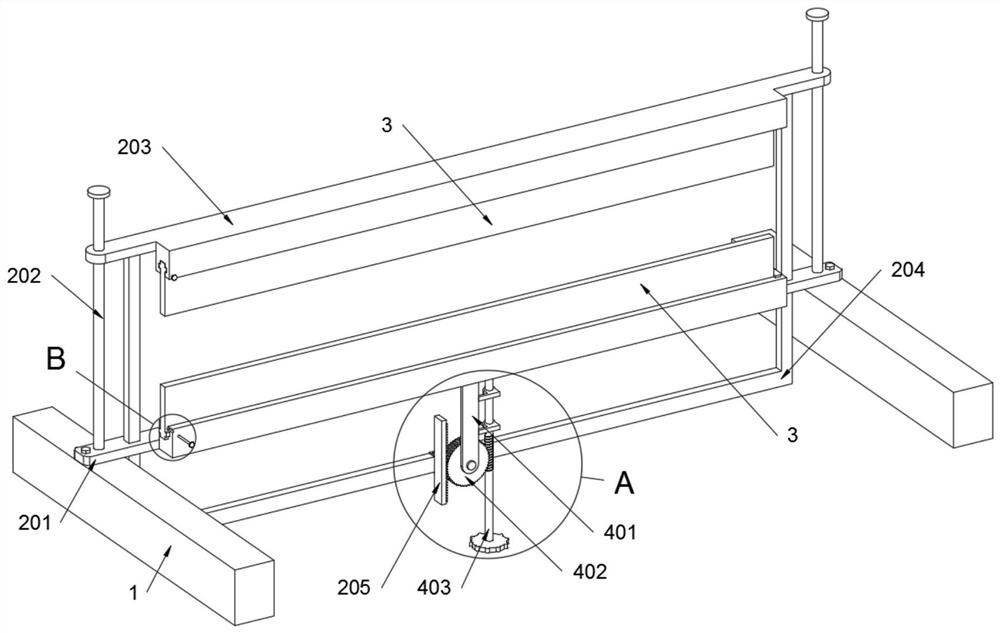

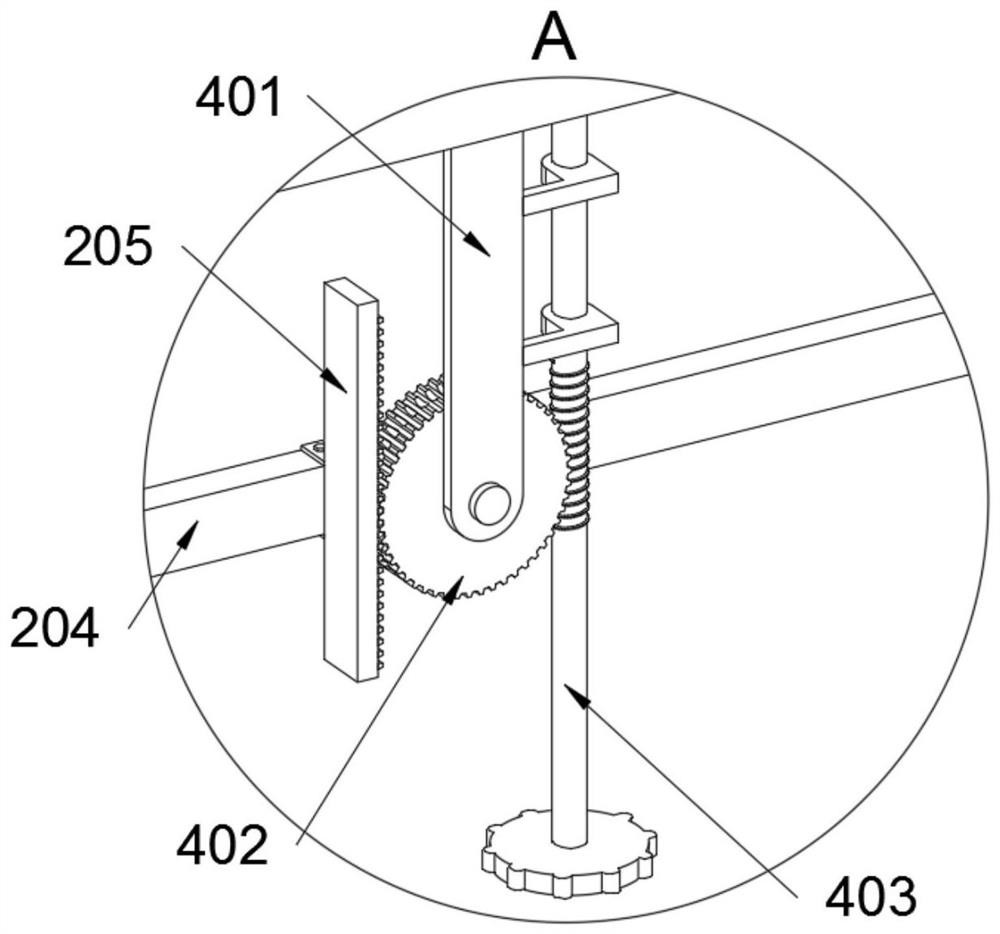

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The invention provides a squeegee mechanism based on special textile fabric coating equipment, which includes an assembly line frame body 1 and a lower knife seat 201; a squeegee structure 2 is installed on the assembly line frame body 1, and a scraper is installed on the squeegee structure 2 3, and the adjustment structure 4 is also installed on the scraping structure 2; refer to as Figure 5 and Image 6, the lower knife seat 201 includes a card slot A20101, a stopper A20102 and a stopper B20103, and a card slot A20101 is opened on the lower knife seat 201, and a scraper 3 is inserted and fixed in the card slot A20101; the card slot A20101 has a "middle" shape structure , and the connecting end of the scraper 3 is also a "middle"-shaped structure; a stopper A20102 and a stopper B20103 are welded in the slot A20101, and both the stopper A20102 and the stopper B20103 are in contact with the connection end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com