Automatic-cleaning-type tea-picking storing device

An automatic cleaning and holding device technology, applied in the field of cleaning, can solve the problems of tea quality reduction, tea appearance damage, tea physical damage, etc., to achieve the effect of reducing separation work, less manual operation, and avoiding physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

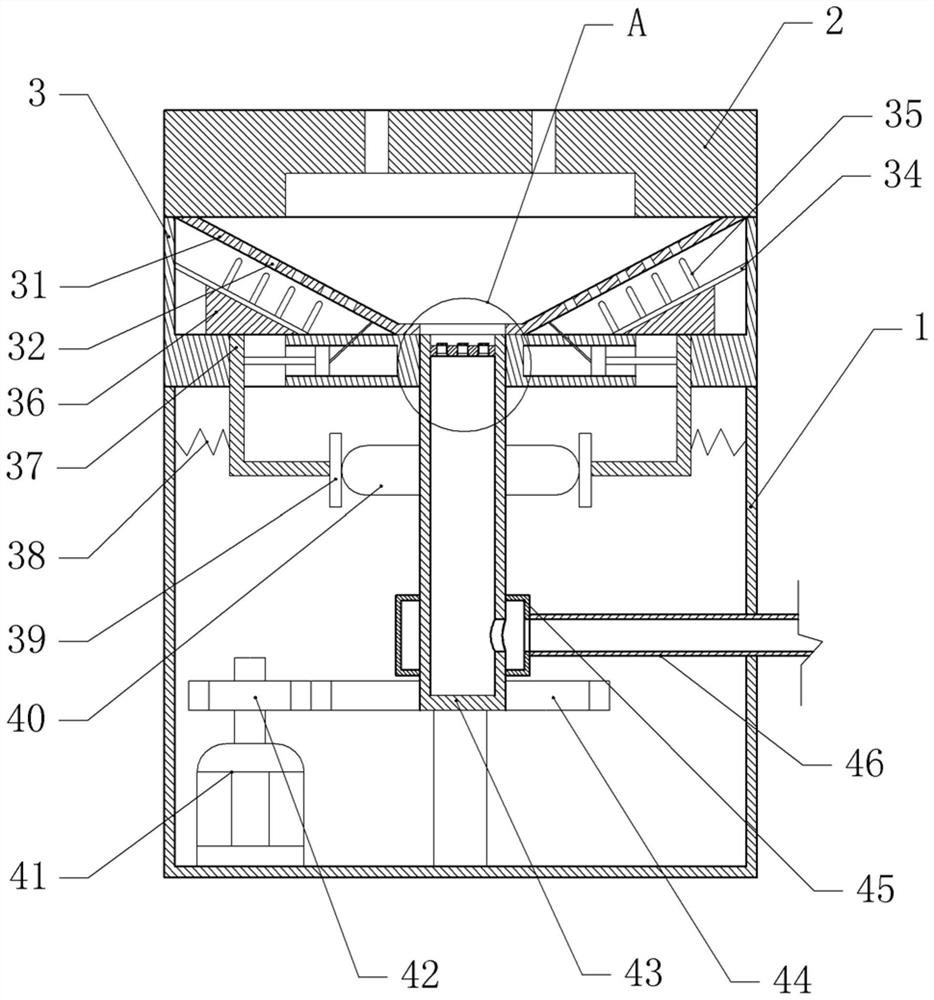

[0036] Basic as attached figure 1 , attached figure 2 And attached image 3 As shown, a self-cleaning type tea-picking storage device includes a cleaning box 3 with an upper opening, and a cover plate 2 is detachably connected to the cleaning box 3, and a pressure relief hole is opened on the cover plate 2.

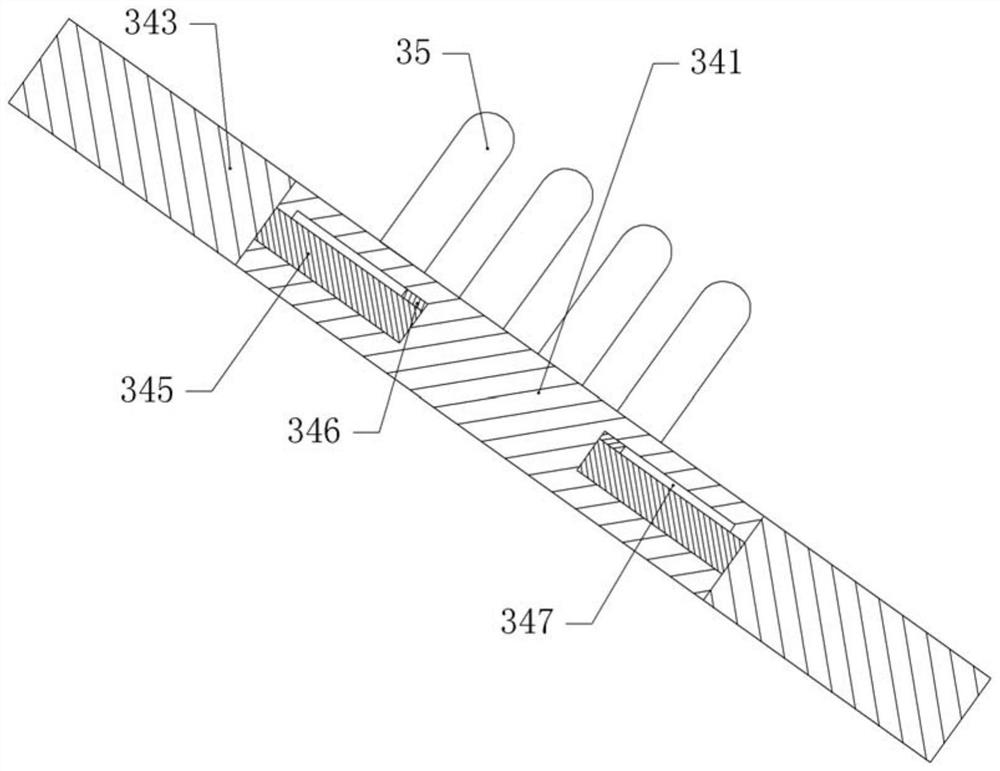

[0037] Both sides of the cleaning box 3 are bolted with a sieve plate 31, the sieve plate 31 is inclined towards the middle of the cleaning box 3, and a number of sieve holes 32 are opened on the sieve plate 31. An inclined anti-blocking plate 34 is arranged in the cavity, and the anti-blocking plate 34 and the sieve plate 31 are located on the same horizontal plane and are horizontal. The blocking shaft 35 and the anti-blocking shaft 35 can extend into the sieve hole 32 of the sieve plate 31, and the two sub-plates 343 are respectively slidably connected with the side walls of the cleaning box. A movable plate 345 slidingly connected with the movable groove 347 is fo...

Embodiment 2

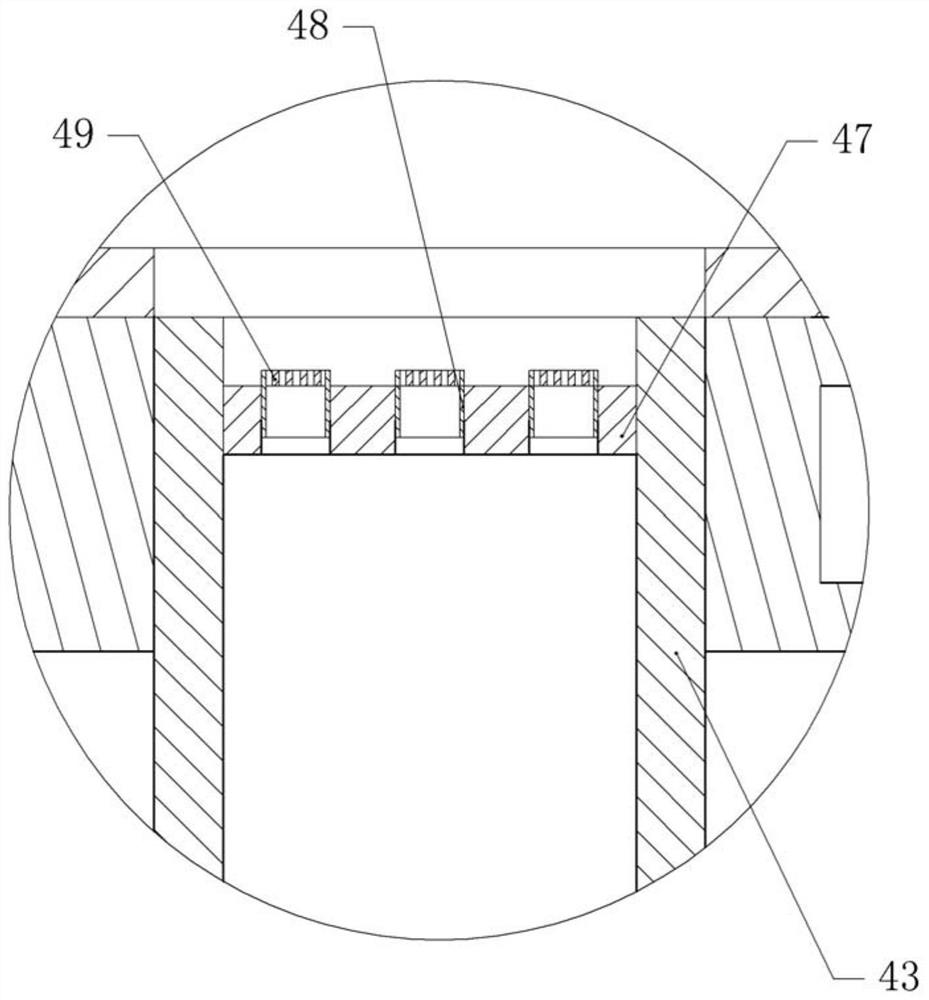

[0045] The difference between embodiment two and embodiment one is that, as attached Figure 4 And attached Figure 5 As shown, there is a water inlet hole on the cover plate 2, and the water inlet hole is connected with a water pump through a pipeline, and the cover plate 2 is rotatably connected with a stirring shaft 21 located below the water hole, and several stirring blades 22 are fixed on the stirring shaft 21 by bolts. . An air plate 52 is fixed inside the branch pipe 48, and air holes with a diameter of 1-6 mm are opened on the air plate 52, and the diameter of the air holes in this embodiment is 4 mm. The rotating shaft 43 is fixed with a blocking plate 5 by bolts, and the upper end of the branch pipe 48 is fixedly connected with the blocking plate 5 by bolts.

[0046] The specific implementation process is as follows:

[0047] The operator sends water into the cleaning box 3 through the water pump and the water hole box, and the water impacts the stirring blade 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com