A low energy consumption nitrogen and oxygen production process for glass kiln

A glass furnace and low energy consumption technology, which is applied in the field of low energy consumption nitrogen and oxygen production process for glass furnaces, can solve the problems of increasing the cost of glass production, reduce exhaust pressure, reduce the number of plates, and reduce overall energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the embodiments and the accompanying drawings. The following examples are only used to illustrate the present invention, but are not intended to limit the scope of the present invention.

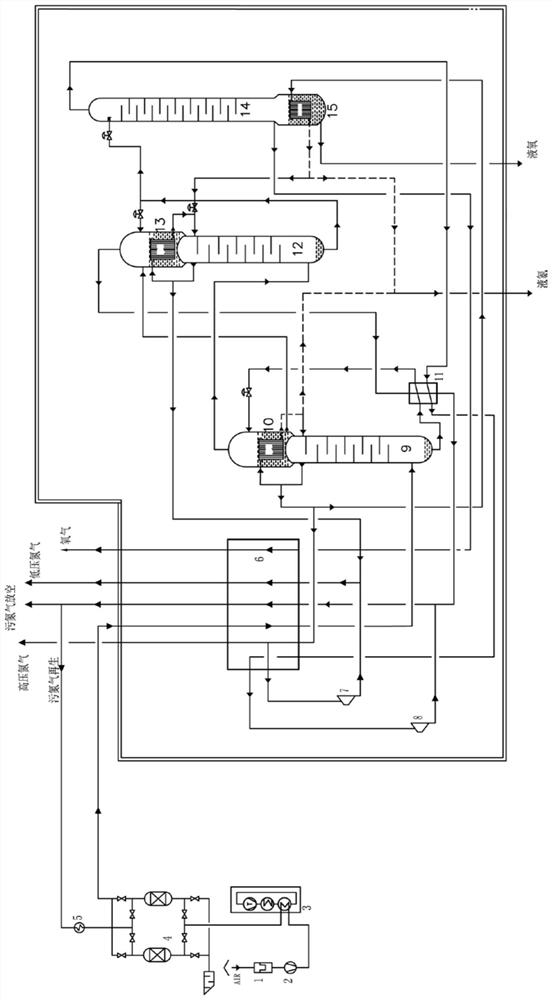

[0036] A low-energy nitrogen and oxygen production process for glass kilns, which utilizes figure 1 The device shown was prepared.

[0037]The shown device includes a filter 1, a turbo air compressor 2, an air pre-cooling unit 3, an alternately used molecular sieve adsorber 4, an electric heater 5, a main heat exchanger 6, a rectification tower I9, and a main condensation evaporator I10 , rectifying column II12, main condensing evaporator II13, rectifying column III14, main condensing evaporator III15, subcooler 11, expander I7 and expander II8;

[0038] Filter 1, turbine air compressor 2, air pre-cooling unit 3, alternately used molecular sieve adsorber 4, electric heater 5 are located outside the cold box, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com