Manufacturing method of stainless steel water pipe connector

A technology of water pipe joints and processing methods, which is applied in the directions of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problem that the locking fixture cannot lock the water pipe joint, the applicability of the locking fixture is single, and the inner and outer wires of the water pipe joint cannot be processed synchronously. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

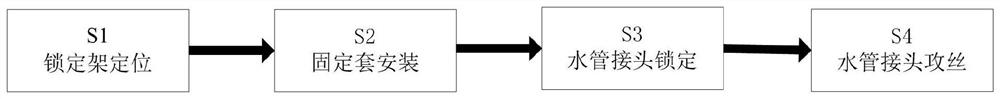

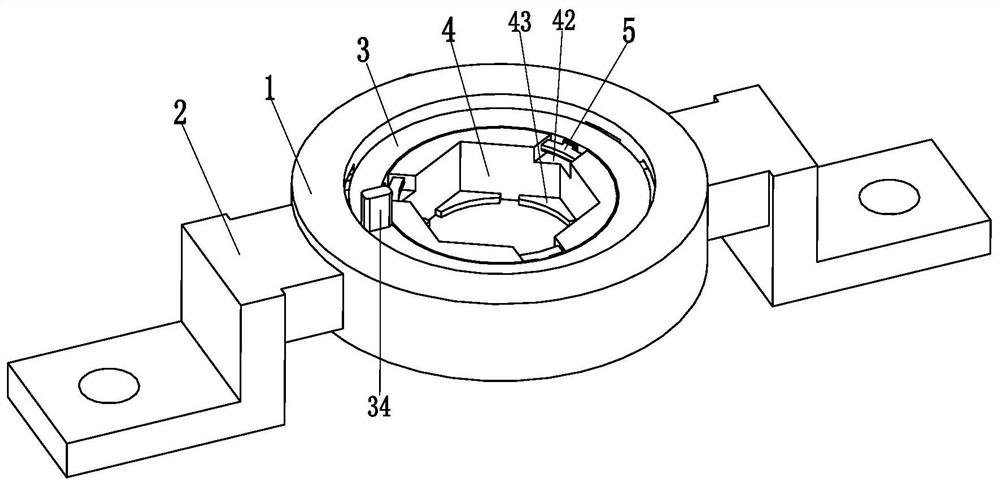

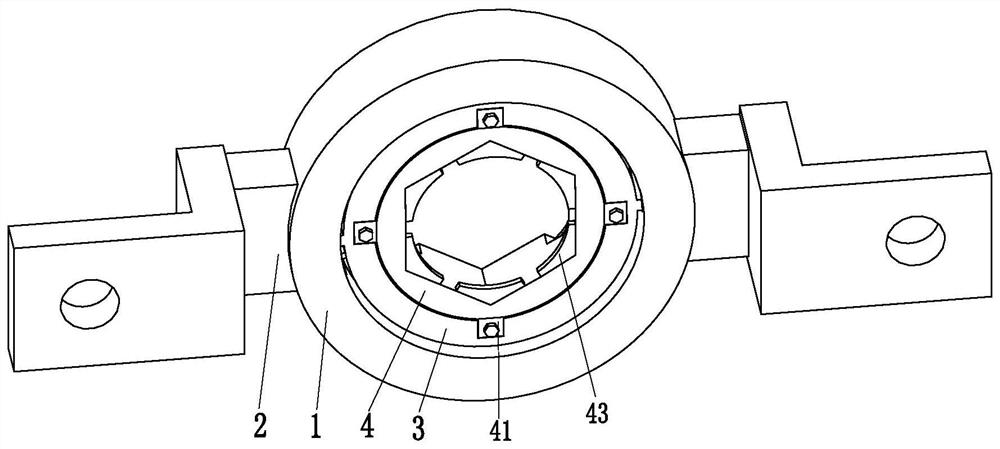

[0036] Such as Figure 1 to Figure 9 As shown, a stainless steel water pipe joint manufacturing and processing method, the stainless steel water pipe joint manufacturing and processing method adopts the following stainless steel water pipe joint processing locking device, the stainless steel water pipe joint processing locking device includes a fixed ring 1, a locking frame 2, a sliding ring 3, and a fixed sleeve 4 , the jacking mechanism 5, the positioning plate 6 and the positioning spring 7, a locking frame 2 is installed on the left and right ends of the fixed ring 1, the locking frame 2 is a Z-shaped structure, and the outer end of the locking frame 2 is provided with a locking hole, the middle part of the inner side wall of the fixed ring 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com