Novel hydraulic cylinder barrel machining and positioning tool

A technology for positioning tooling and hydraulic cylinders, applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of long processing time, reduced processing accuracy, and many processes, and achieve high processing efficiency and improved processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

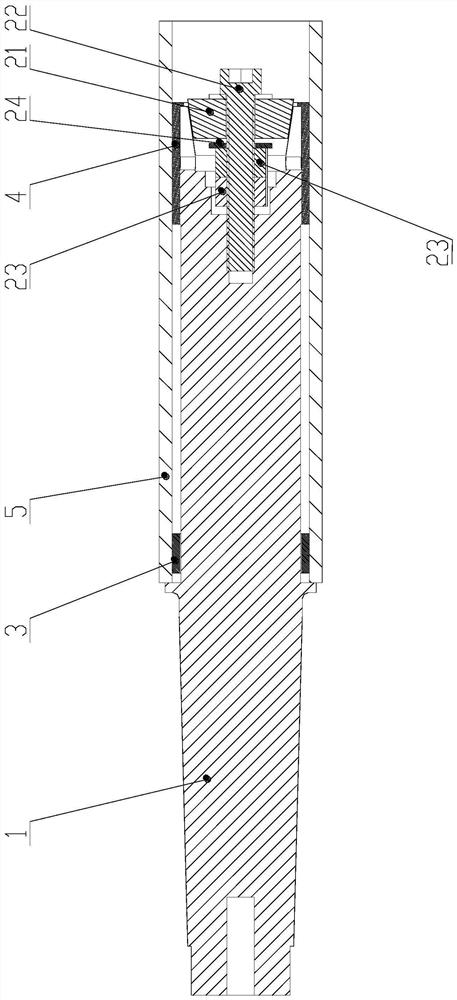

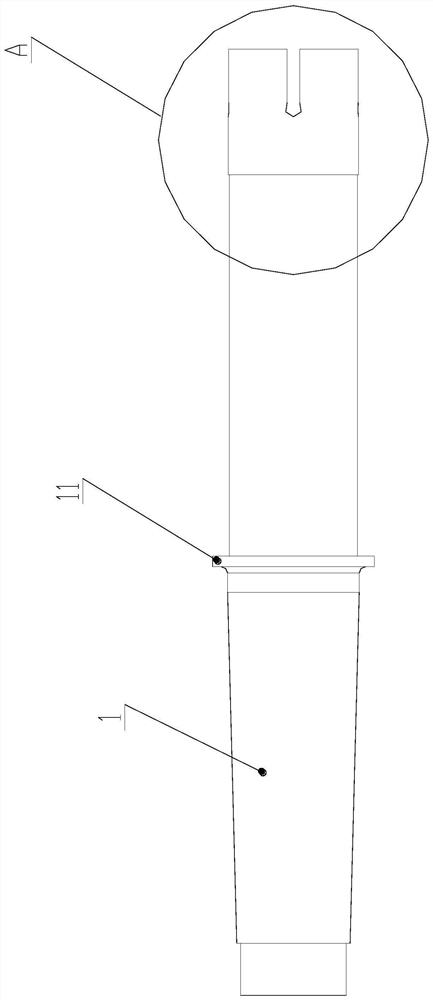

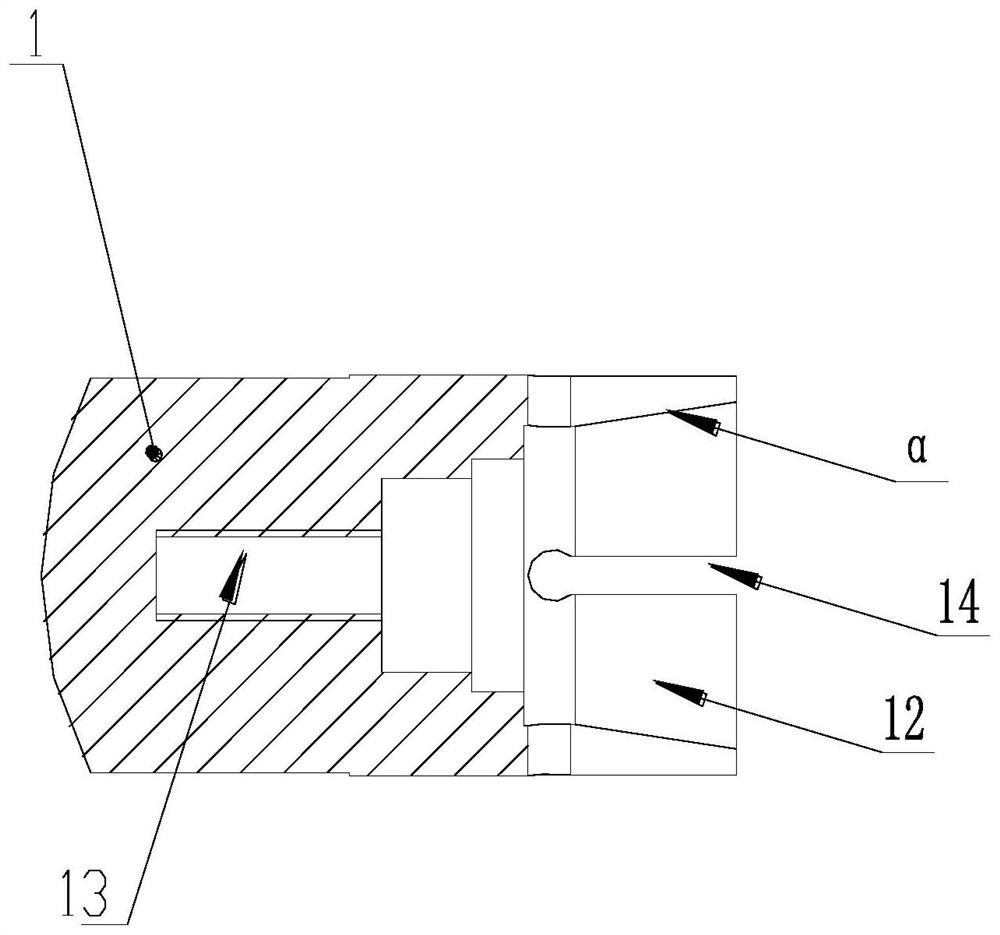

[0019] Such as Figure 1 to 3 Shown

[0020] The positioning tool includes a positioning body 1 and an expansion assembly.

[0021] The outer wall of the positioning body 1 fits the contour of the inner hole of the hydraulic cylinder barrel 5. The outer wall of the positioning body 1 extends with a retaining ring 11 that matches the front face of the hydraulic cylinder barrel 5, and the rear face of the positioning body 1 is provided with an expansion groove 12 and an expansion groove 12 The direction is consistent with the axial direction of the positioning body 1, the expansion groove 12 has a threaded hole 13 on the front side groove wall, the rear circumferential groove wall of the expansion groove 12 has a taper α, and the positioning body 1 has a circumferential uniform distribution on the rear surface Two expansion joints 14 extending axially along the positioning body 1 and penetrating the rear of the positioning body 1, a thin-walled expansion clamp that can be expanded o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com