Processing device for calcium magnesium silicate decorating plate

A calcium magnesium silicate and processing device technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems that affect people's use, and there is no installation mechanism for processing devices, so as to achieve the convenience of clamping, fixing and processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

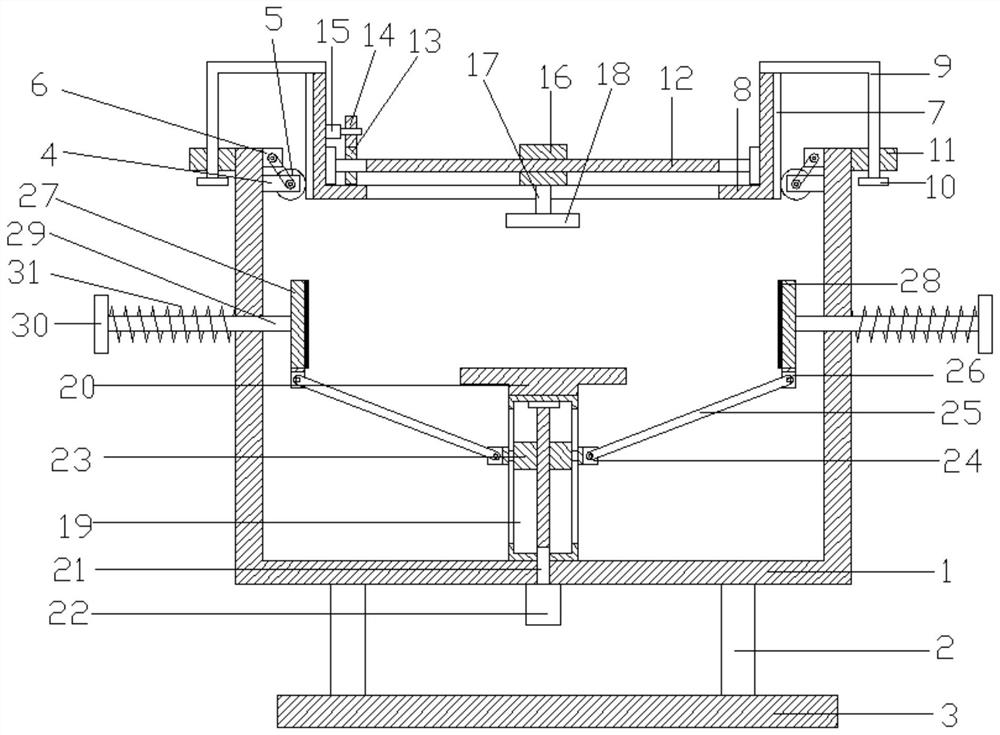

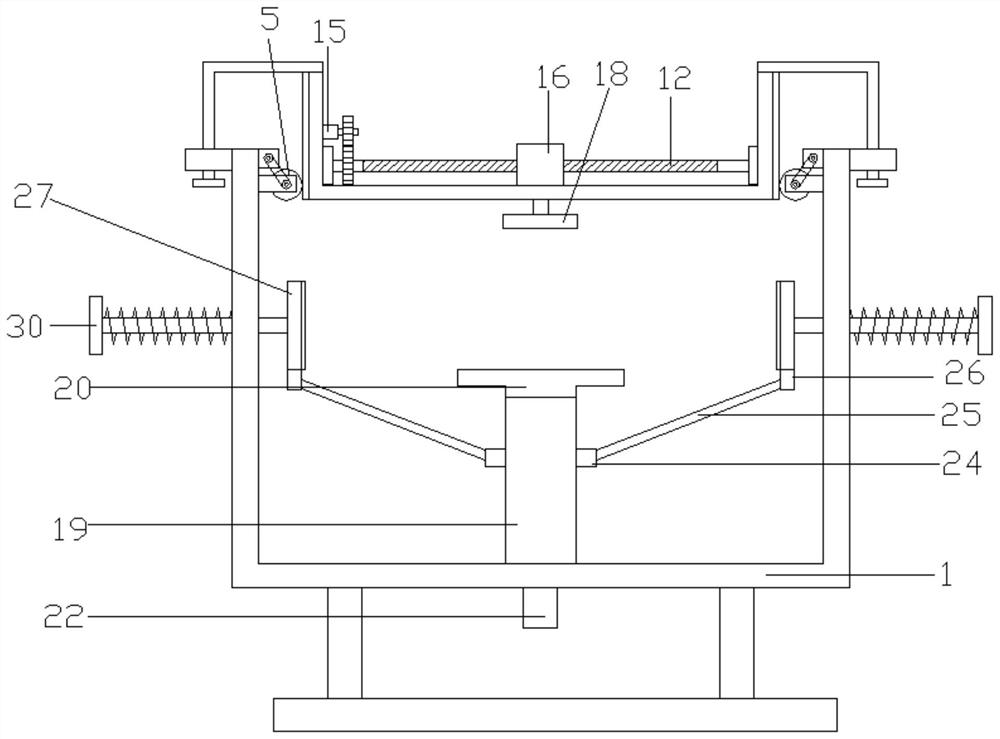

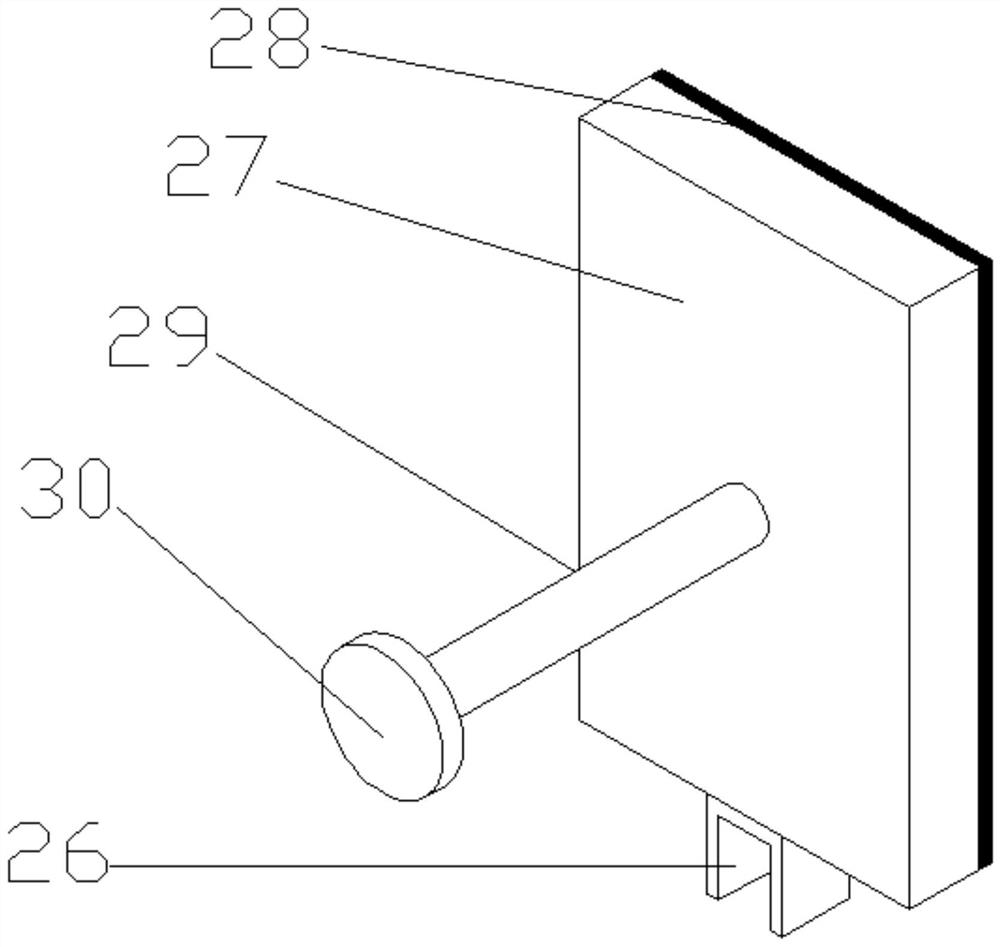

[0024] refer to Figure 1~3 , in an embodiment of the present invention, a processing device for a calcium magnesium silicate decorative board includes a support frame 1, the four corners of the lower side of the support frame 1 are fixedly installed with supporting legs 2, and the lower side of the supporting legs 2 is fixedly installed with a bottom plate 3, Can effectively support the whole equipment, the middle end of the bottom of the support frame 1 is provided with a chute 19, and the upper side of the chute 19 is fixedly equipped with a support platform 20, which can effectively support the calcium magnesium silicate decorative board to be processed, and facilitate the silicic acid The clamping process of the calcium magnesium decorative board, the second threaded rod 21 is installed inside the chute 19, the upper side of the second threaded rod 21 is connected with the chute 19 through the bearing seat, and the second threaded rod 21 is installed on the lower side. Th...

Embodiment 2

[0029] The difference from Embodiment 1 is that a limit rod 9 is provided outside the upper end of the connecting frame 8, and the limit rod 9 is arranged inside the fixed block 11, and the fixed block 11 is fixedly installed on the outer wall of the support frame 1, and is located 11 The first limit block 10 on the limit rod 9 on the lower side, when the connecting frame 8 moves up and down, the limit rod 9 moves synchronously inside the fixed block 11, so that the connecting frame 8 can be limited processing to ensure the stable movement of the connecting piece 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com