Pedal type turnover device for machining assembly line

A technology of mechanical processing and flipping devices, which is applied in the direction of workpiece clamping devices, workbenches, hand-held tools, etc., can solve the problems of reducing the working efficiency of parts, loss, and fasteners falling, so as to improve work efficiency and use Find handy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

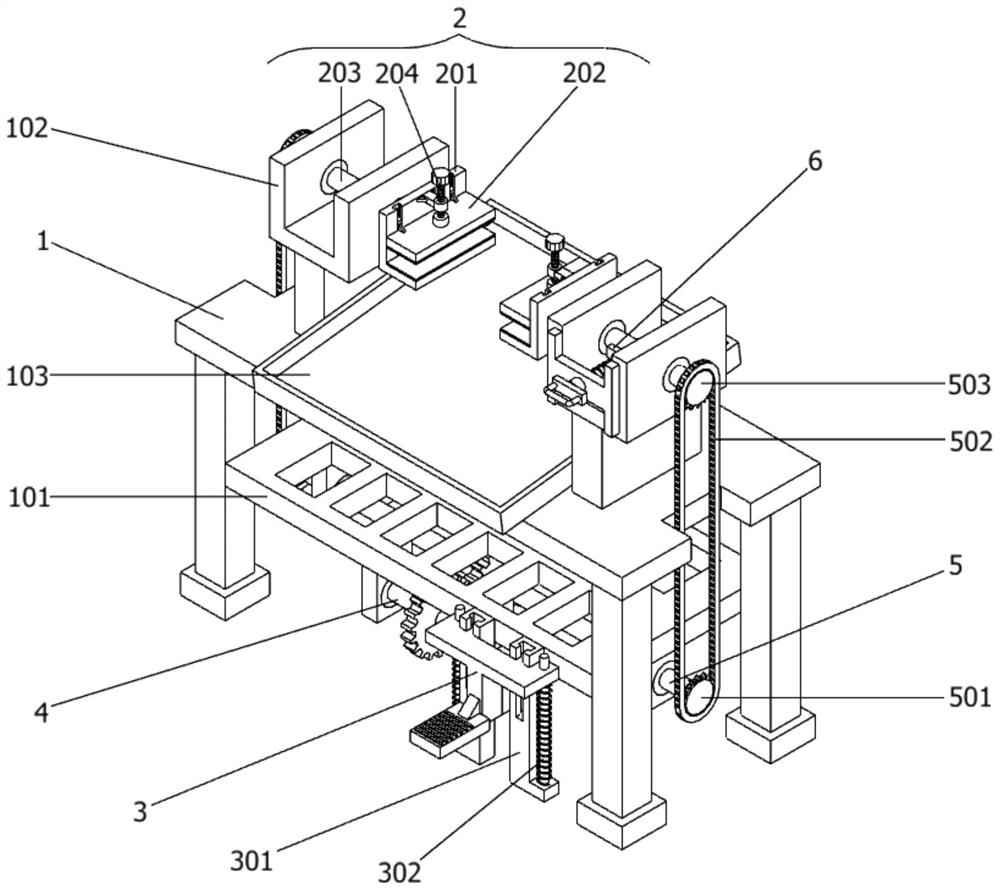

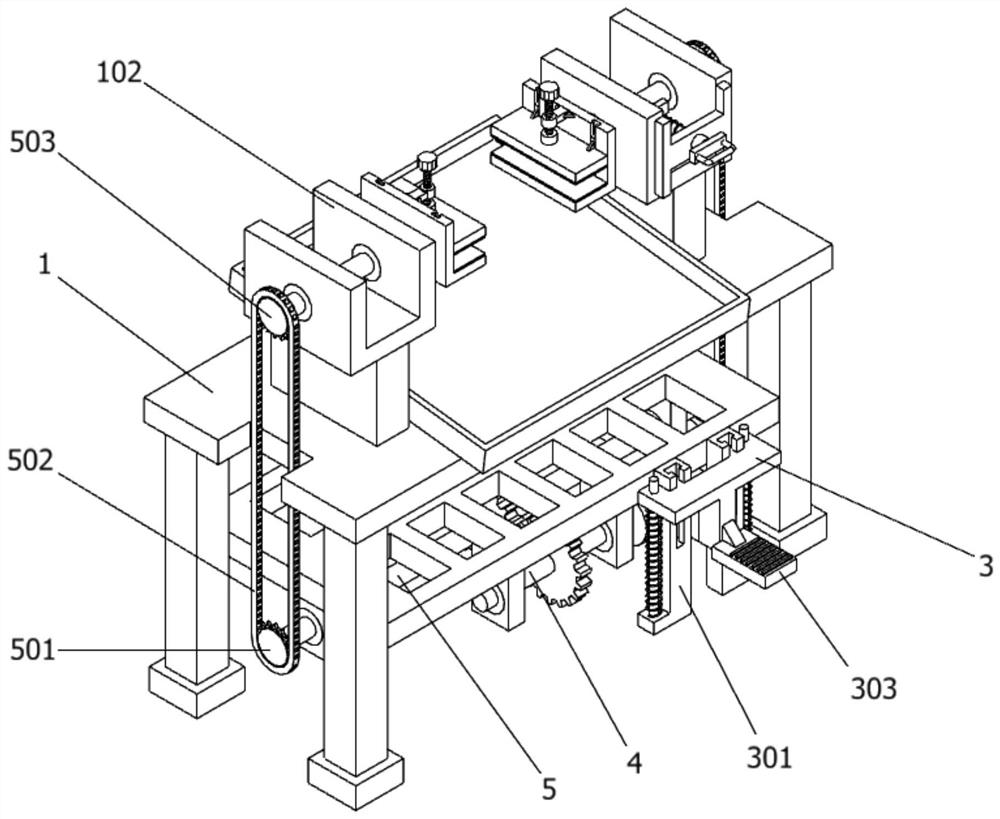

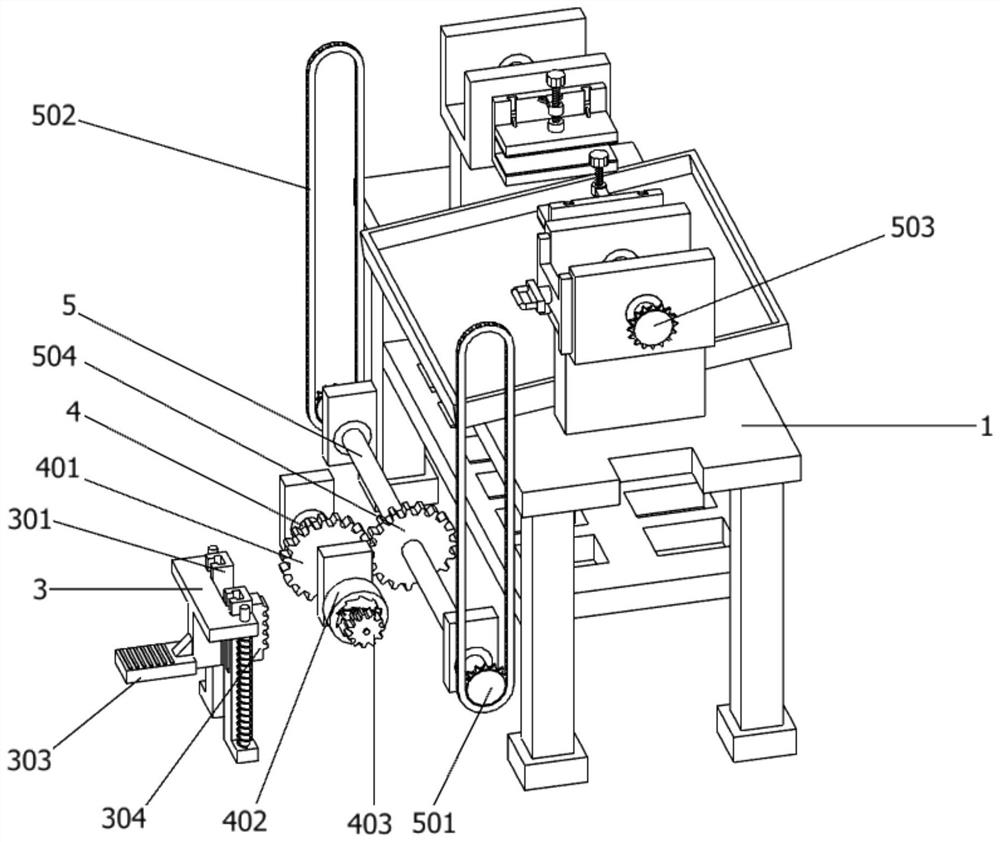

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides a foot-operated turning device on an assembly line in mechanical processing, which includes: an assembly workbench 1, the upper part of which is symmetrically rotated and connected with two turning and clamping mechanisms 2, and the turning and clamping mechanism 2 includes L-shaped fixed splint 201, movable splint 202, overturning shaft 203, clamping screw 204, screw rotating sleeve 205, first T-shaped slider 206 and threaded cylinder 207, the outer vertical surface of L-shaped fixed splint 201 is provided with overturning shaft 203 , and the overturning shaft 203 is connected to the bearing support plate 102 through bearing rotation, and the inner vertical surface of the L-shaped fixed splint 201 is symmetrically provided with two T-shaped slide grooves, and the L-shaped fixed splint 201 is passed through two T-shaped slides. The slot is slidably connected with a movable splint 202, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com