A semicircular template release agent applicator

A release agent and applicator technology, which is applied to the field of the semicircular template release agent applicator, can solve the problems of inconvenient application of the release agent, and achieve the effect of simplifying the operation and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

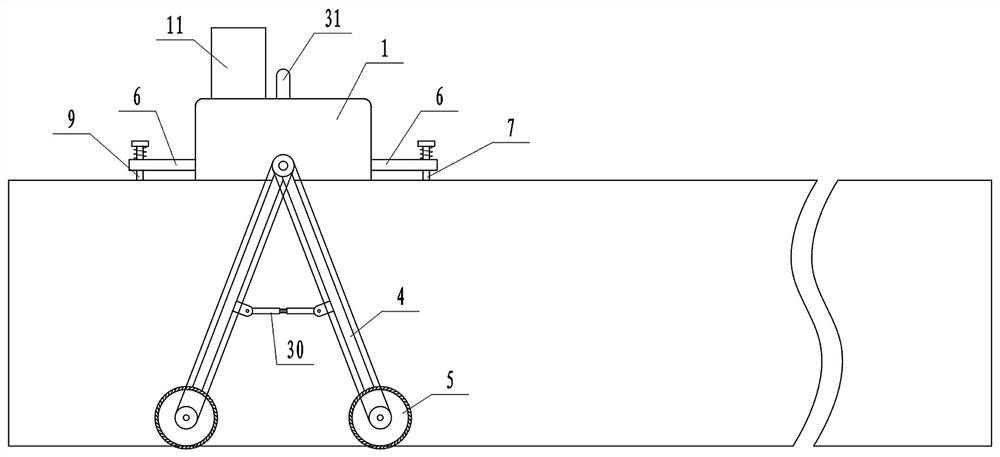

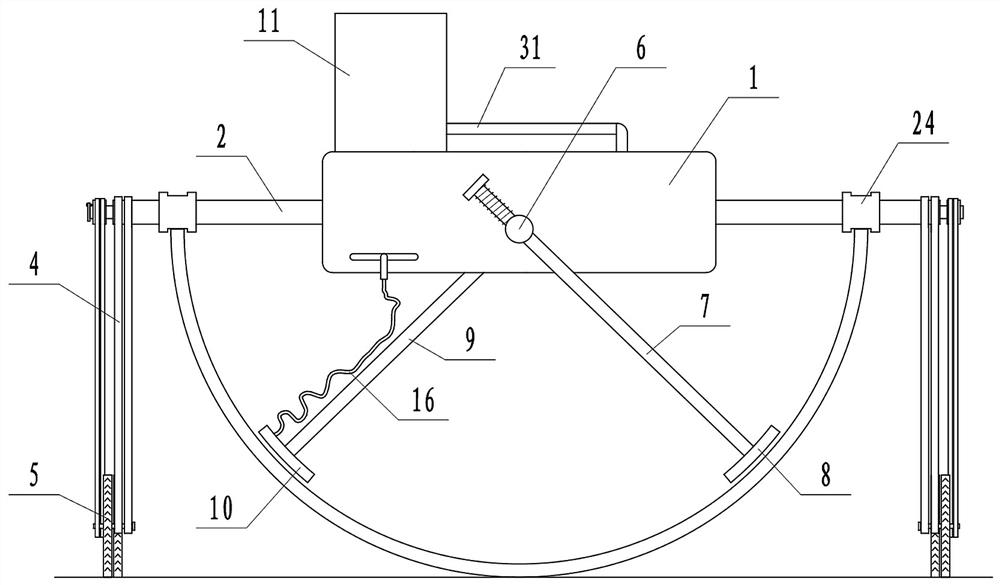

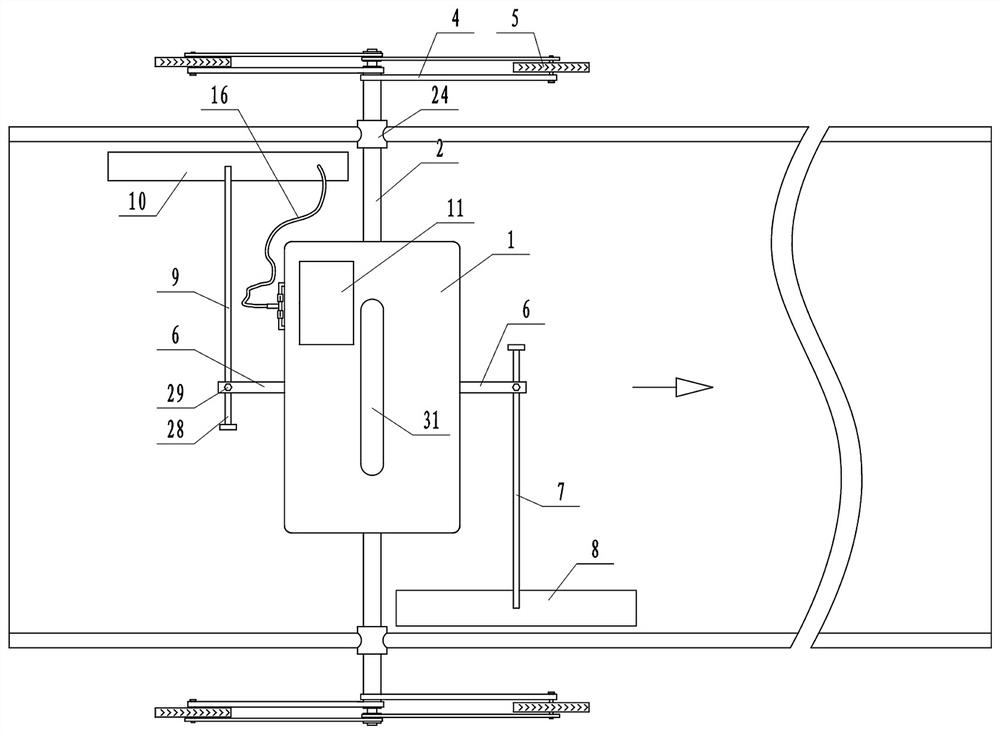

[0016] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Depend on Figure 1 to Figure 7 Provided, the present invention includes a housing 1 placed in the front and rear directions. There is a sleeve 2 in the front and rear directions on both sides of the housing 1. The sleeve 2 communicates with the inside of the housing 1. The sleeve 2 is inserted with a Rotating rotating shaft 3, two connecting rods 4 are installed on the front end and rear end of rotating shaft 3, and wheels 5 are installed on the lower end of each connecting rod 4, and the rotation of multiple wheels 5 can drive rotating shaft 3 to rotate;

[0018] The middle part of the housing 1 is inserted with two left and right horizontal shafts 6, the rotation of the rotating shaft 3 can drive the left and right two horizontal shafts 6 to rotate synchronously and reversely, and each horizontal shaft 6 can ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com