Height adjusting system and seat fixing device

A height adjustment and seat technology, which is applied in vehicle seats, movable seats, transportation and packaging, etc. It can solve the problems of scratching the seat, complicated operation, scratches on the slide rail bolts, etc., and achieves accurate adjustment and convenient operation , to avoid the effect of scratching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

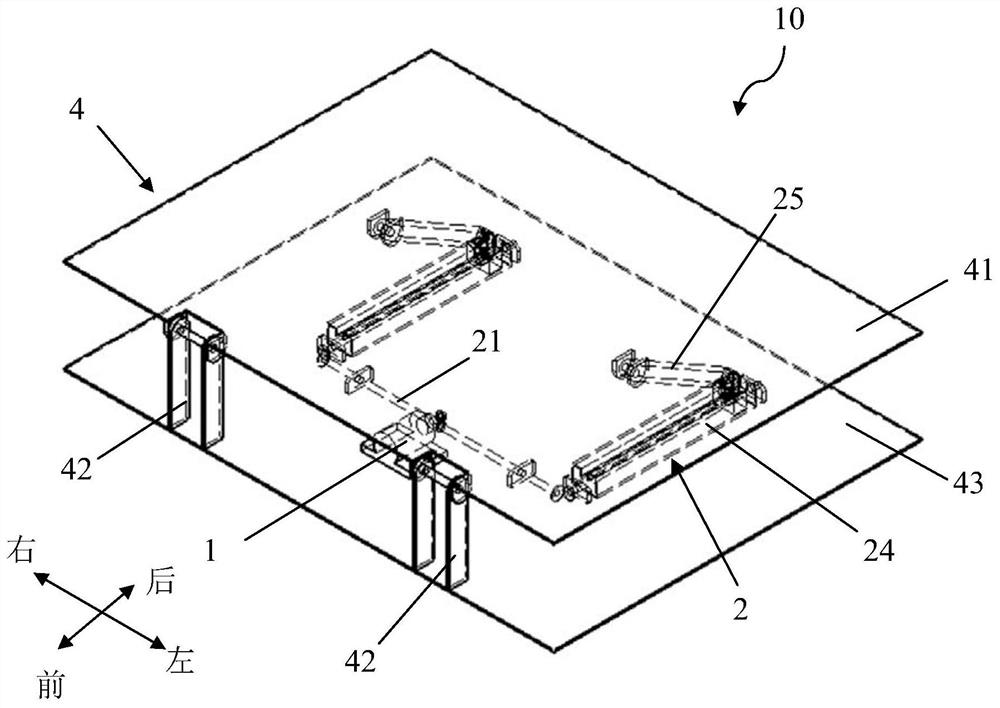

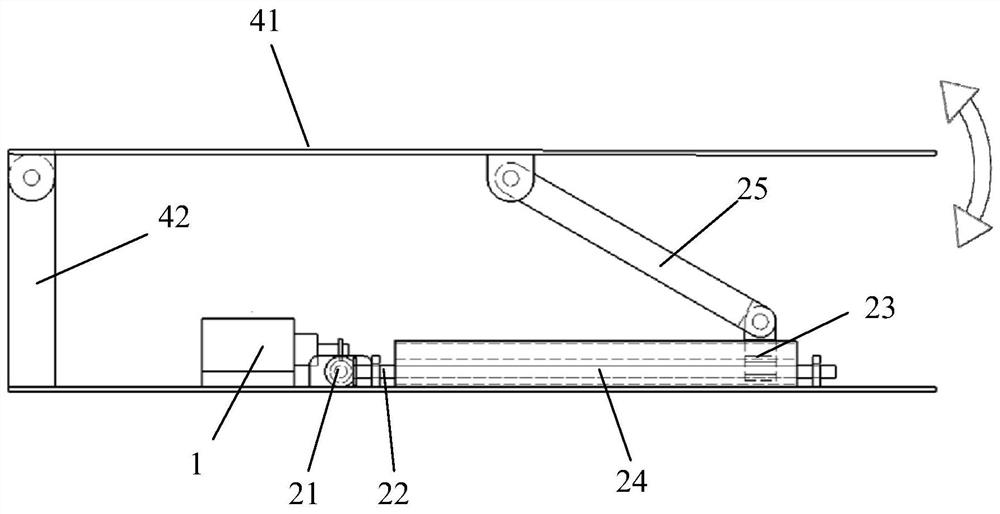

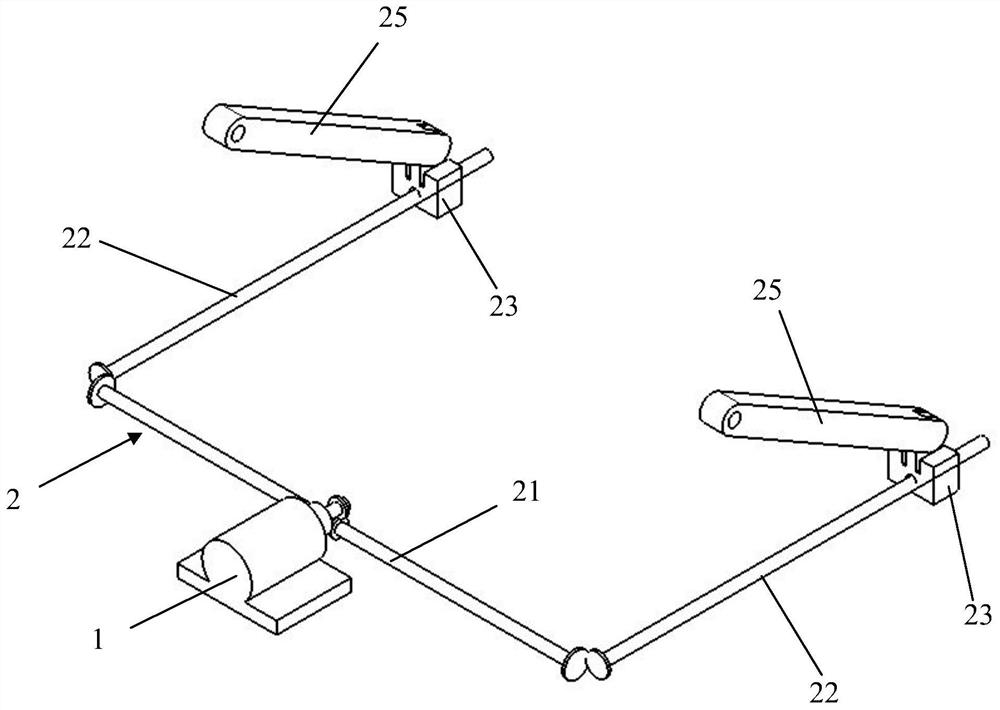

[0058] Such as Figure 1-10 As shown, the height adjustment system 10 includes a height adjustment motor 1, a connecting rod assembly 2, a self-locking assembly 3 and a turning assembly 4,

[0059] After the height adjustment motor 1 drives the connecting rod assembly 2 to move, the connecting rod assembly 2 drives the turning assembly 4 to turn up and down,

[0060] The self-locking assembly 3 is installed on the connecting rod assembly 2, when the height adjustment motor 1 drives the connecting rod assembly 2, the self-locking assembly 3 unlocks the connecting rod assembly 2, so that the connecting rod assembly 2 can drive the turning assembly 4 to turn up and down;

[0061] When the overturning component 4 is pressed down by the seat, the overturning component 4 drives the connecting rod component 2 , and the connecting rod component 2 drives the self-locking component 3 to lock with the connecting rod component 2 .

[0062] In this embodiment, the height adjustment system...

Embodiment 2

[0106] Such as Figure 11 As shown, the seat fixing device includes the height adjustment system 10 in the first embodiment and its modification.

[0107] Further, the seat fixing device also includes a seat positioning system, the seat positioning system includes a longitudinal positioning assembly 20 and a transverse positioning assembly 30, the longitudinal positioning assembly 20 is used for longitudinally positioning the seat, and the transverse positioning assembly 30 is used for horizontally positioning seat.

[0108] Specifically, as Figure 11 As shown, the longitudinal positioning assembly 20 and the lateral positioning assembly 30 are installed on the flipping plate 41. After the longitudinal positioning assembly 20 and the lateral positioning assembly 30 are positioned with the seat, when the flipping plate 41 is turned up and down, the seat can be adjusted to adjust the height and height together. angle.

[0109] The longitudinal positioning assembly 20 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com