Height adjustment system and seat anchorage

A height adjustment and seat technology, which is applied in the direction of movable seats, vehicle seats, transportation and packaging, etc., can solve the problems of uncontrollable force, complicated operation, and scratching of the seat by pressing the slide rail inward, so as to avoid the seat Deformation of the chair frame, easy operation, and the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

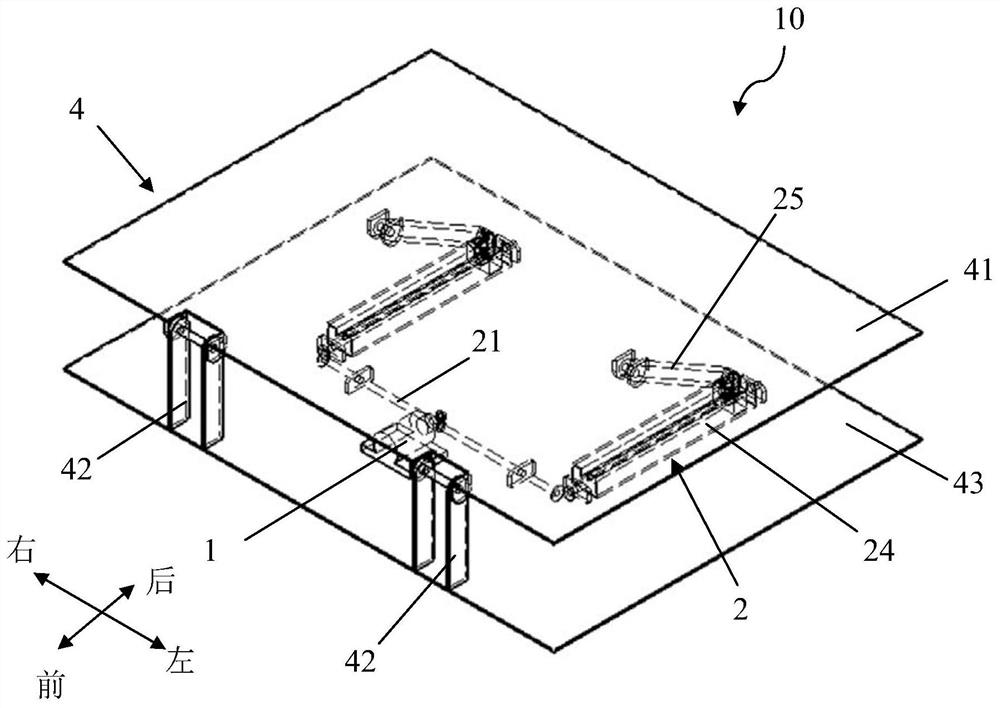

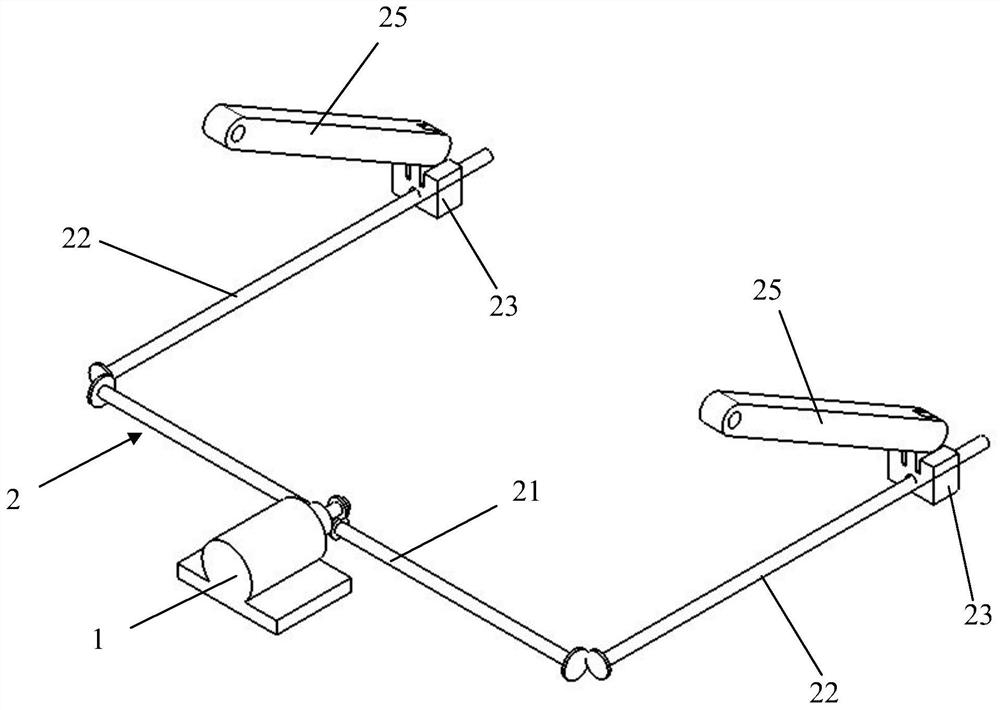

[0067] There are two slide rails 24, which are arranged in the front-rear direction of FIG.

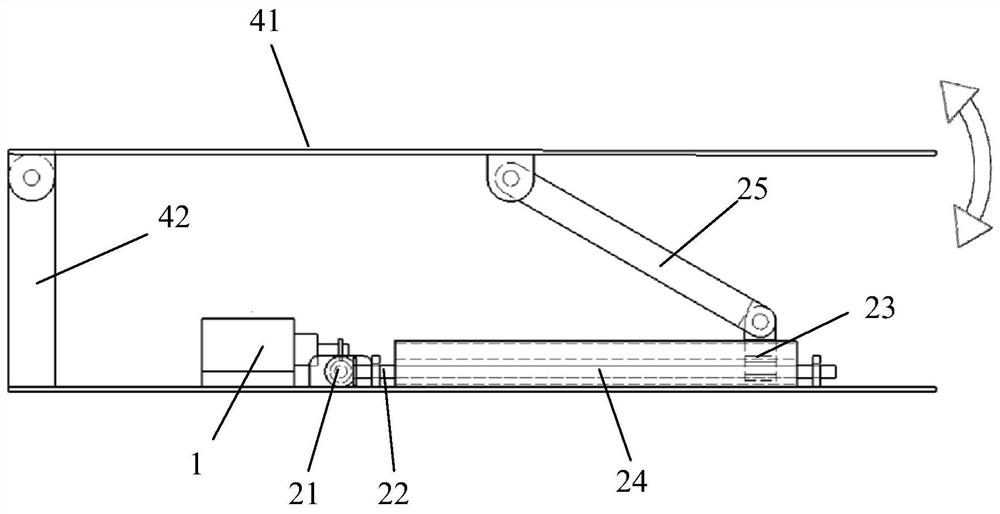

[0068] The slider 24 is rotatably connected to one end of the push-pull rod 25, and the other end of the push-pull rod 25 is rotatably connected to the flip assembly 4.

[0070] Further, as shown in Figures 4-8, the self-locking assembly 3 is installed in the slider 23, and is sleeved outside the second screw rod 22;

[0072] When the turning assembly 4 is pressed down by the seat, the sliding block 23 is locked with the sliding rail 24 from the self-locking assembly 3.

[0077] After adjusting to a suitable height and angle, as shown in FIG. 5, when the turning assembly 4 is pressed down by the seat, the turning assembly

[0083] As shown in FIG. 8, the slider 23 is provided with a cylindrical cavity 232, and the sleeve 31 is installed in the cylindrical cavity 232.

[0084] As shown in FIG. 5 , when the flipping assembly 4 is slightly pressed down by the seat, the flipping assembly 4 dri...

Embodiment 2

[0106] As shown in FIG. 11 , the seat fixing device includes the height adjustment system 10 in the first embodiment and its modifications.

[0107] Further, the seat fixing device also includes a seat positioning system, and the seat positioning system includes a longitudinal positioning assembly

[0108] Specifically, as shown in FIG. 11 , the longitudinal positioning assembly 20 and the lateral positioning assembly 30 are mounted on the flip plate 41, and the longitudinal

[0109] The longitudinal positioning assembly 20 includes a first longitudinal positioning block 201 and a second longitudinal positioning block 202, and the first longitudinal sliding rail

[0110] The lateral positioning assembly 30 includes a first lateral positioning block 301 and a second lateral positioning block 302, and the first lateral sliding rail

[0111] The first longitudinal slide rail 203 and the second longitudinal slide rail 204 are arranged in parallel on the flip plate 41 in the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com