Flexible material automatic centering, clamping, rotating and boxing mechanism

An automatic centering and rotating mechanism technology, applied in packaging and other fields, can solve problems such as inability to industrialize, immature automatic boxing mechanism for flexible materials, waste of human resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

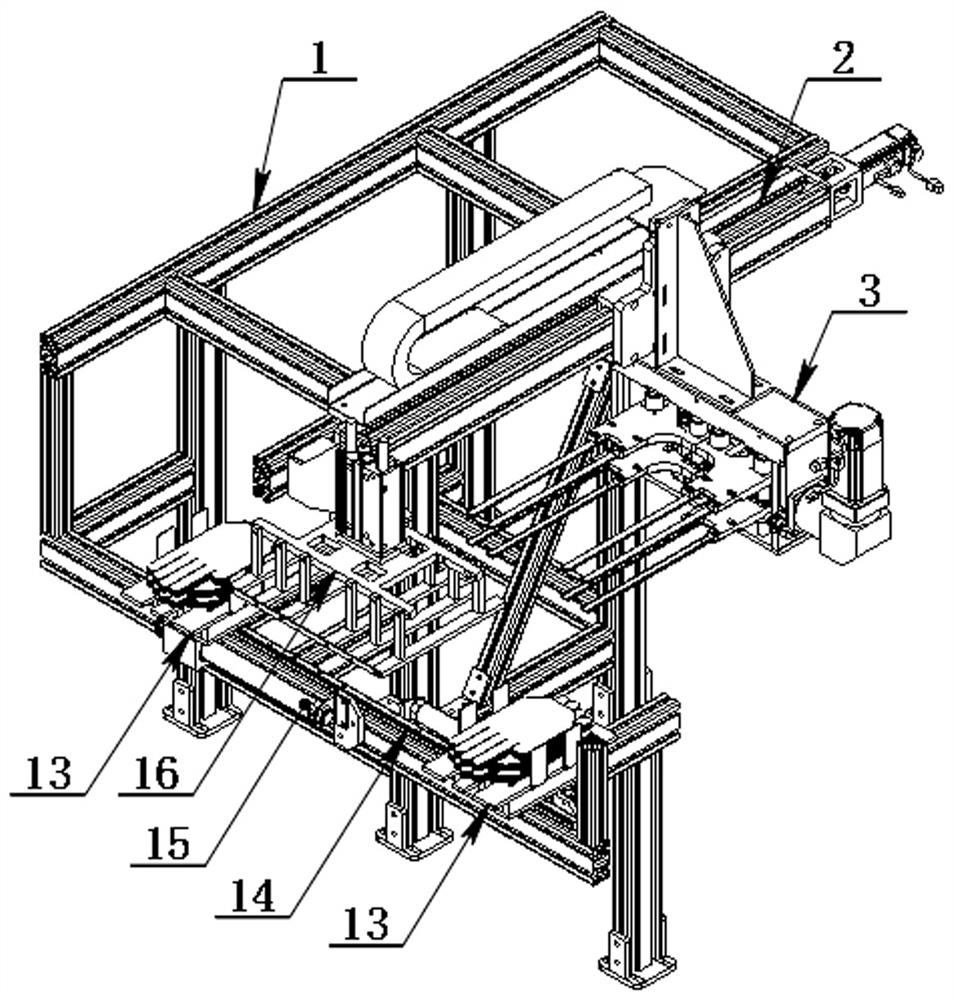

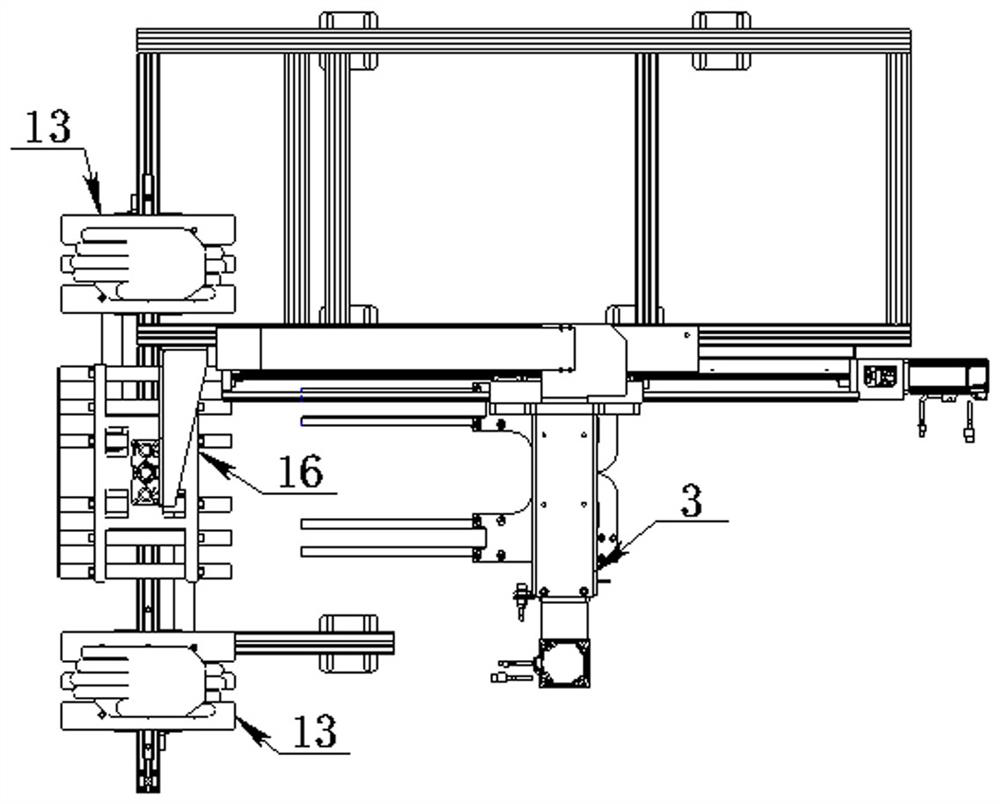

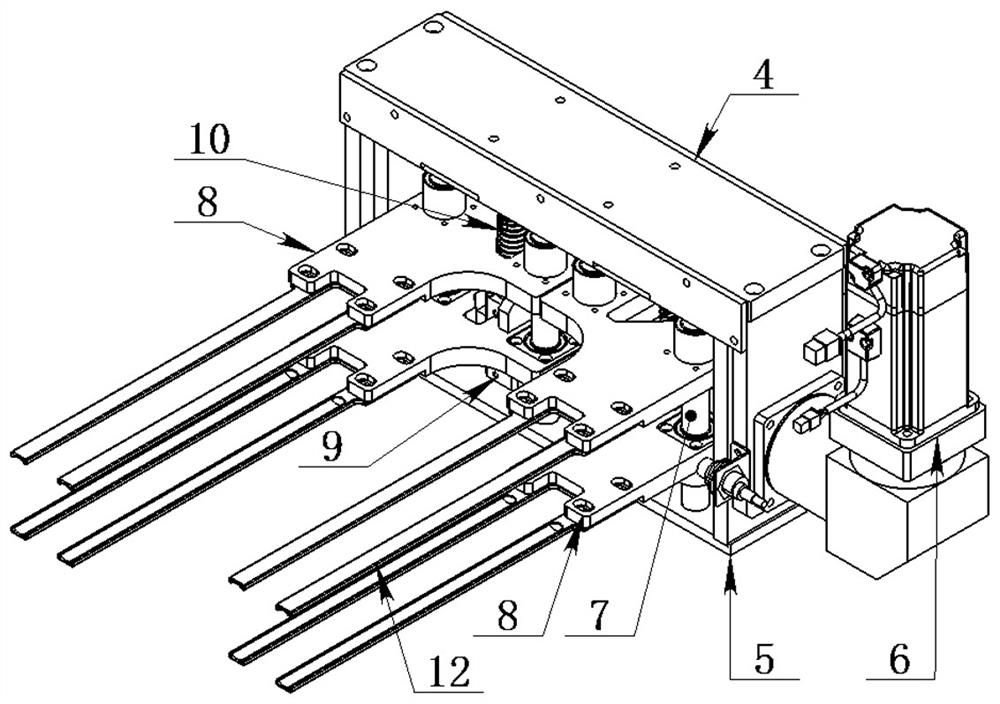

[0025] Such as figure 1 , 2 As shown, the automatic centering, clamping, and rotating cartoning mechanism for flexible materials of the present invention includes: a fixed chassis 1, and a reciprocating movement for driving the centering, clamping, and rotating mechanism 3 mounted on one side of the top frame of the mechanism-fixed chassis 1 The linear travel unit 2 (the linear travel unit is guided by a linear module and driven by a ball screw, which can realize precise travel and stop position control during the box loading process, making the box loading process more precise), the centering clamping and rotating mechanism 3 It is arranged on the outside of the linear walking unit 2 in a suspended manner, and a loading table 13 and a material fetching and pressing device 16 are installed on the front part of the lower frame of the mechanism-fixed chassis 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com