Sinker device for knitting machine

A sinker and knitting machine technology, applied in the field of parts and components, can solve the problems of limiting the application range of the loom, single action, etc., and achieve the effects of small resistance, simple structure and small force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

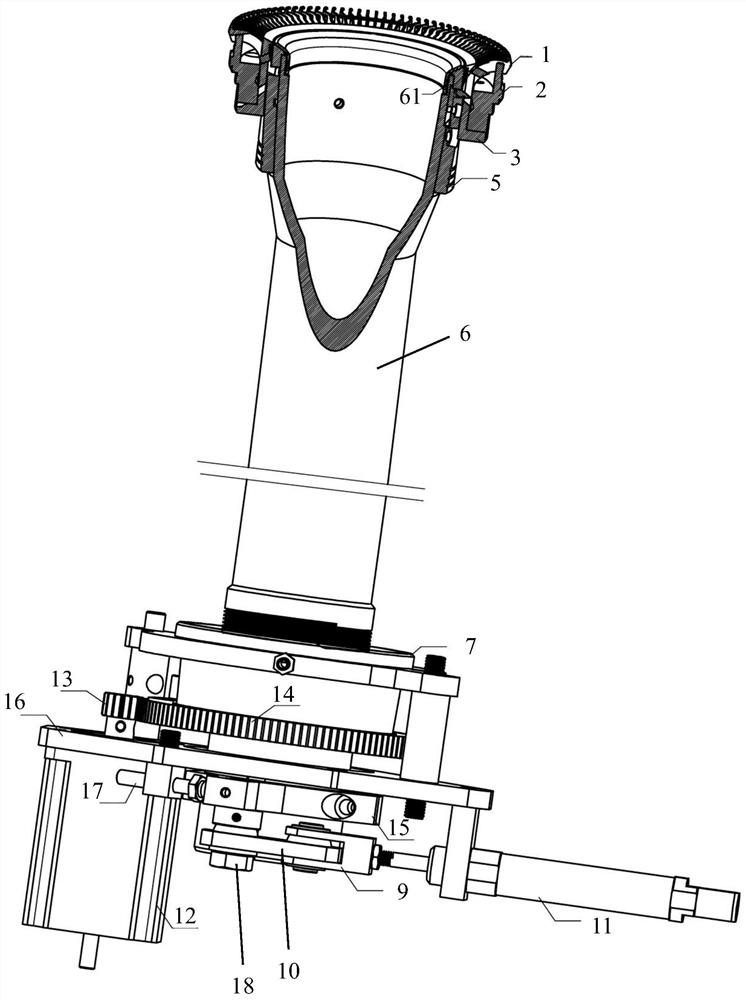

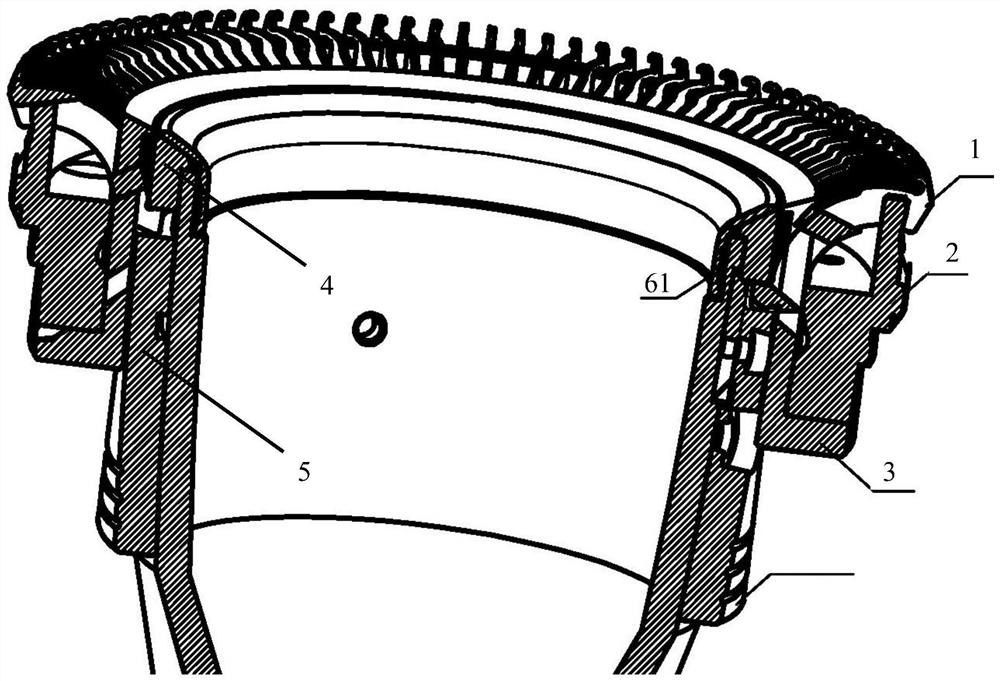

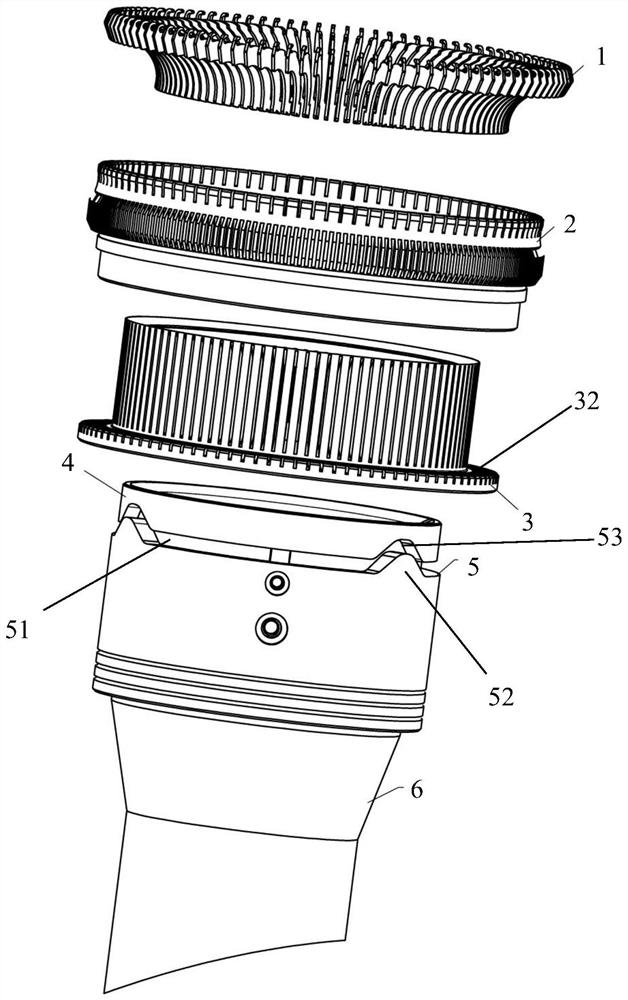

[0022] Embodiments of the present invention are described below with reference to the drawings, in which like parts are denoted by like reference numerals. In the case of no conflict, the following embodiments and the technical features in the embodiments can be combined with each other.

[0023] The design principle of the present invention is that the lower end of the sinker is set in the needle track of the sinker cam, the sinker guiding mechanism is arranged outside the sinker cam, the sinker passes through the guiding mechanism, and the falling object tube is arranged inside the sinker cam , the bottom of the drop tube is lifted and rotated back and forth through the control mechanism, thereby driving the lifting of the sinker triangle and the swinging of the two convex points of the sinker triangle to restrain the sinker from expanding inside and outside and the wire inlet of the sinker to change the wire inlet position back and forth.

[0024] figure 1 A perspective vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com