Floating garbage fishing device for sewage treatment

A sewage treatment and salvage device technology, applied in water/sewage treatment, water/sludge/sewage treatment, cleaning of open water surface, etc., can solve the problems of short service life, heavy labor, heavy net bag load, etc., to avoid The effects of salvage failure, extended use time, and large salvage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

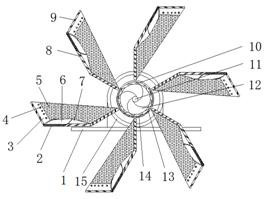

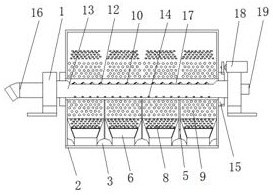

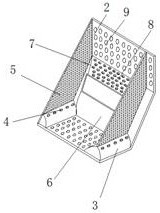

[0027] refer to Figure 1-4 , a floating garbage salvage device for sewage treatment, comprising two mounting frames 1, a conveying shell 13 is fixedly installed between the two mounting frames 1, and a discharge pipe 16 is fixedly mounted on the end of the conveying shell 13, conveying The other end of housing 13 is fixedly installed with main driving motor 19, and between the output shaft of main driving motor 19 and the interior of conveying housing 13, conveying shaft 11 is installed through bearing, and the outer side of conveying shaft 11 is fixedly installed with spiral distribution. The push paddles 12 are provided, and the top of the conveying housing 13 is provided with a strip-shaped feed slot 17. The outer side of the conveying housing 13 is fixedly equipped with two rotating rings 15, and the outer sides of the two rotating rings 15 are A plurality of ring-shaped salvage bucket mechanisms 2 are fixedly installed, and an auxiliary drive motor 18 is fixedly installe...

Embodiment 2

[0035] refer to figure 1 and Figure 3-5 , a floating garbage salvage device for sewage treatment. Compared with Embodiment 1 in this embodiment, a plurality of support rods 22 are fixedly installed on the tops of the two installation frames 1, and solar energy is fixedly installed between the top ends of the support rods 22. The solar panel 21 and the bottom of the solar panel 21 are fixedly equipped with a spray mechanism 20, and the device can provide auxiliary power supply through the solar panel 21, thereby reducing the demand for power during the operation of the device and reducing the cost of sewage treatment.

[0036] The spraying mechanism 20 comprises a spraying pipe and a spraying branch pipe which is screwed to the bottom of the side of the spraying pipe, and the spraying branching pipe is distributed obliquely, and a sewage pump is fixedly installed at the end of the spraying pipe. In the sewage treatment pool, the water in the pool is sent to the spray mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com