Precise steel latticed column mounting method applied to foundation pit support engineering

A technology for supporting steel lattice columns and foundation pits, which is applied in basic structural engineering, pillars, columns, etc., can solve the problems of poor construction quality, skewed and non-parallel installation of steel lattice columns, etc. Solid structure, good guiding and limiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]The present invention will be described in further detail below in conjunction with the accompanying drawings.

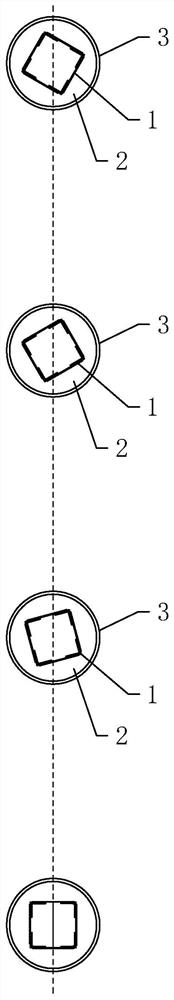

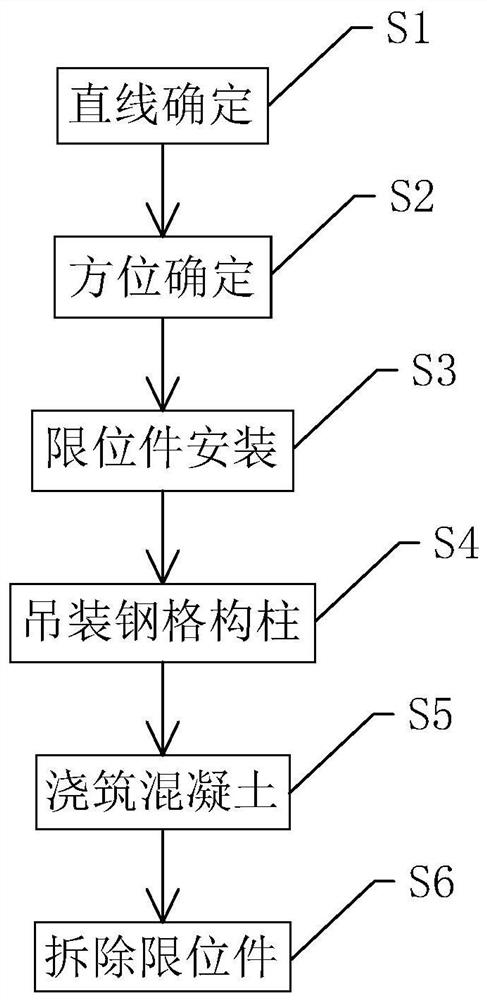

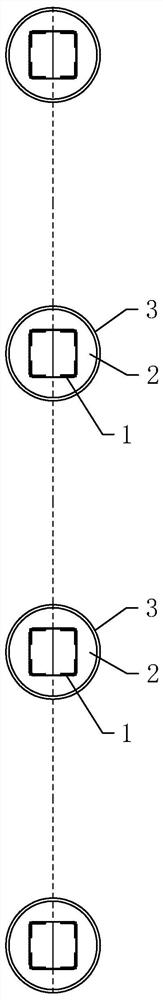

[0040] refer to figure 2 and image 3 , is a precise installation method of steel lattice columns applied in foundation pit support engineering disclosed by the present invention, comprising the following steps: straight line determination S1: draw a line on the ground along the pile hole positions of at least two cast-in-place piles 2 or Pull the rope, the straight line drawn or the straight line represented by the pull rope is the standard installation direction of the subsequent steel lattice column 1; orientation determination S2: press the compass on the above straight line, and make the compass pointer coincide with the direction of the above straight line, and record the compass pointer The orientation pointed to; calibration piece installation S3: Place the calibration piece 4 on the top of the steel sheath 3 used for the construction of the cast-in-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com