Keel mounting structure of assembly type detachable wallboard system and mounting method

An installation structure and prefabricated technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of low construction efficiency and inconvenient hooking, and achieve improved construction efficiency, easy snap-in, and simple leveling process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

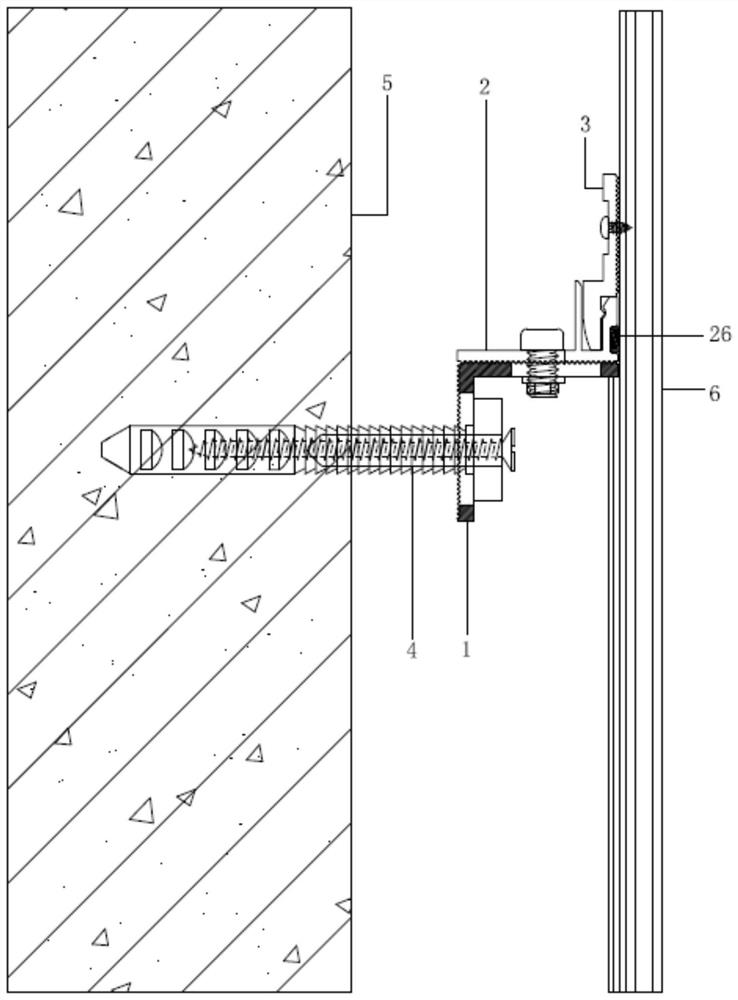

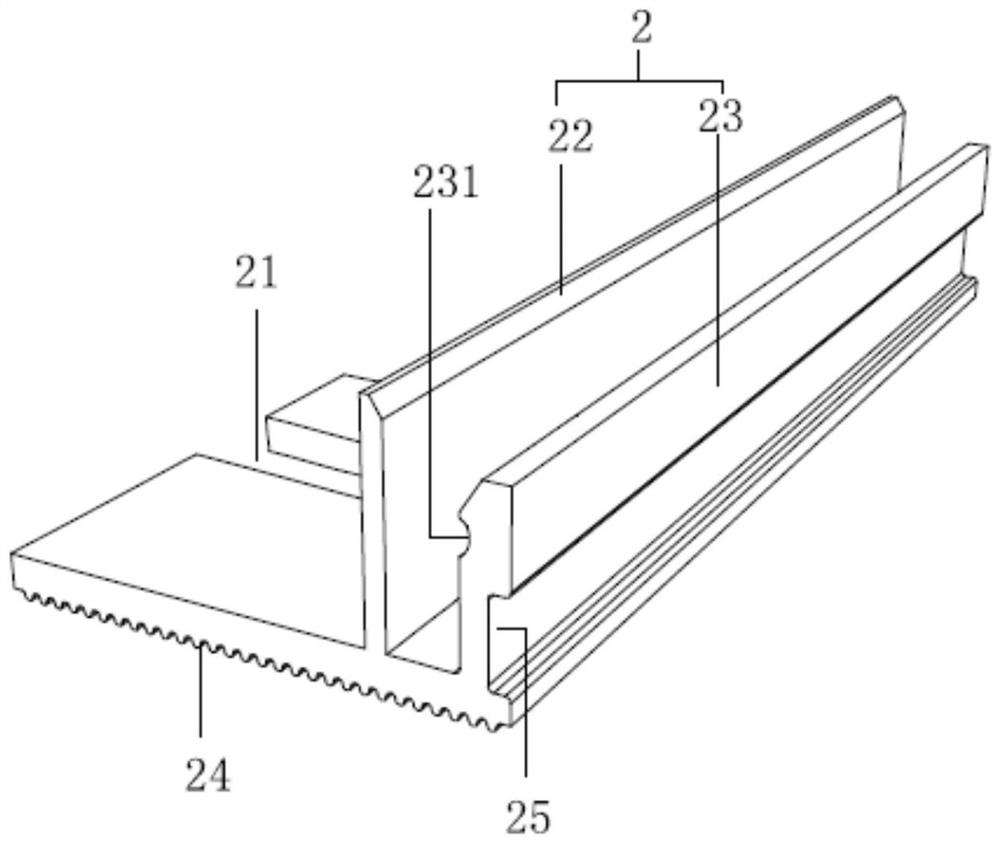

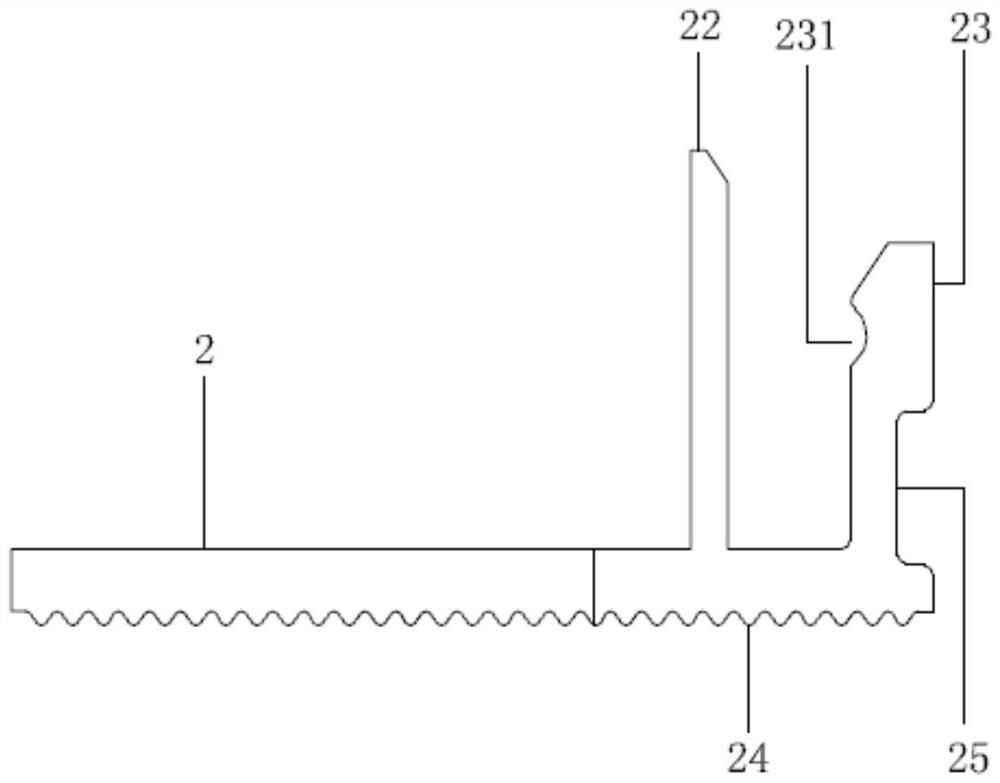

[0029] see Figure 1 to Figure 6 , the figure shows the keel installation structure of a prefabricated detachable wall panel system provided by Embodiment 1 of the present invention, including corner bracket 1, joist 2 and wall panel hanger 3, corner bracket 1 includes the first connection perpendicular to each other part 11 and the second connecting part 12, the first connecting part 11 is fixedly installed on the base wall surface 5 through the fastener 4, the second connecting part 12 is provided with a second waist-shaped hole 121, and the keel 2 is fixed and installed on the On the second connecting part 12, the keel 2 is provided with a notch 21 corresponding to the second waist hole 121, the bolt is passed through the second waist hole 121 and the notch 21, and the keel 2 is provided with a first limiting plate arranged in parallel 22 and the second limiting plate 23, the height of the first limiting plate 22 is greater than the height of the second limiting plate 23, t...

Embodiment 2

[0038] see Figure 1 to Figure 6 , the figure shows the keel installation structure of a prefabricated detachable wall panel system provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The first connecting portion 11 is provided with a first waist-shaped hole 111 through which the fastener 4 passes. The surface of the first connecting portion 11 is provided with a plurality of anti-slip grooves 112 arranged in parallel.

[0039] The first waist-shaped hole on the first connecting part allows the corner bracket to move up and down, fine-tunes the installation position of the keel, and improves installation accuracy. The anti-slip grooves provided on the surface of the first connecting part increase the friction between the corner bracket and the base wall, and improve the stability of the keel installation structure.

Embodiment 3

[0041] see Figure 1 to Figure 6 , the figure shows the keel installation structure of a prefabricated detachable wallboard system provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The bottom of the keel 2 is provided with multiple first ribs 24 arranged in parallel, and the second connecting portion 12 is provided with a first groove 122 corresponding to the first ribs 24 .

[0042] The first convex rib at the bottom of the keel cooperates with the first groove on the surface of the corner bracket, which increases the friction between the keel and the corner bracket, avoids the positional deviation of the force between the keel and the corner bracket, and improves the stability of the keel installation structure . In addition, the interval between the first ribs at the bottom of the keel is 1mm. When matching with the first groove on the surface of the corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com