Limiting jacking device for steel frame of tunnel opening and shed and its construction method

A technology of jacking device and limiting device, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of inability to directly form a working surface, structural difficulties, narrow bridge deck and tunnel opening space, etc. The effect of quality shed hole construction and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in detail below in combination with specific embodiments.

[0056] The invention relates to a position-limiting jacking device for a steel frame of a shed at the entrance of a tunnel. Independent pile foundations are arranged on both sides of an existing bridge and concrete beams with pre-embedded ground anchor bolts are covered. Lay slide guides on the concrete beams, use jacks and limit devices, and cooperate with lifting supports to realize the overall in-place installation of the assembled and formed steel frame on site. Finally, the construction of the shed is completed by setting auxiliary facilities such as steel wire mesh ropes on the steel frame.

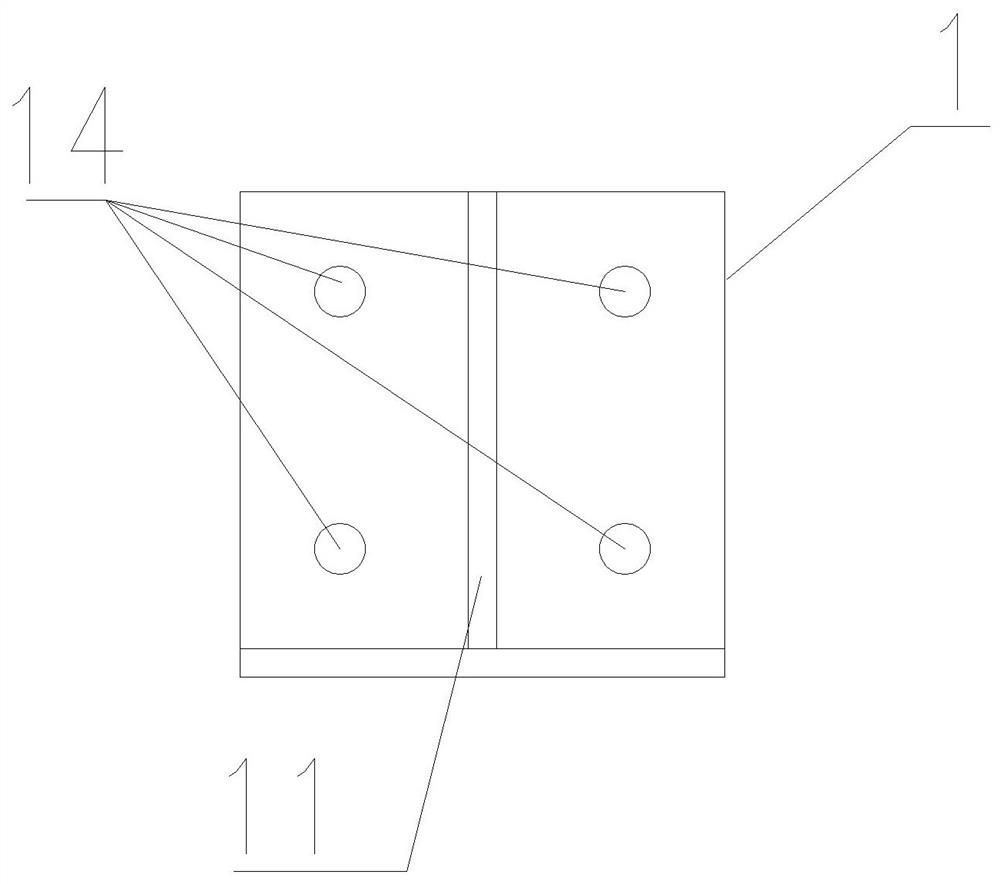

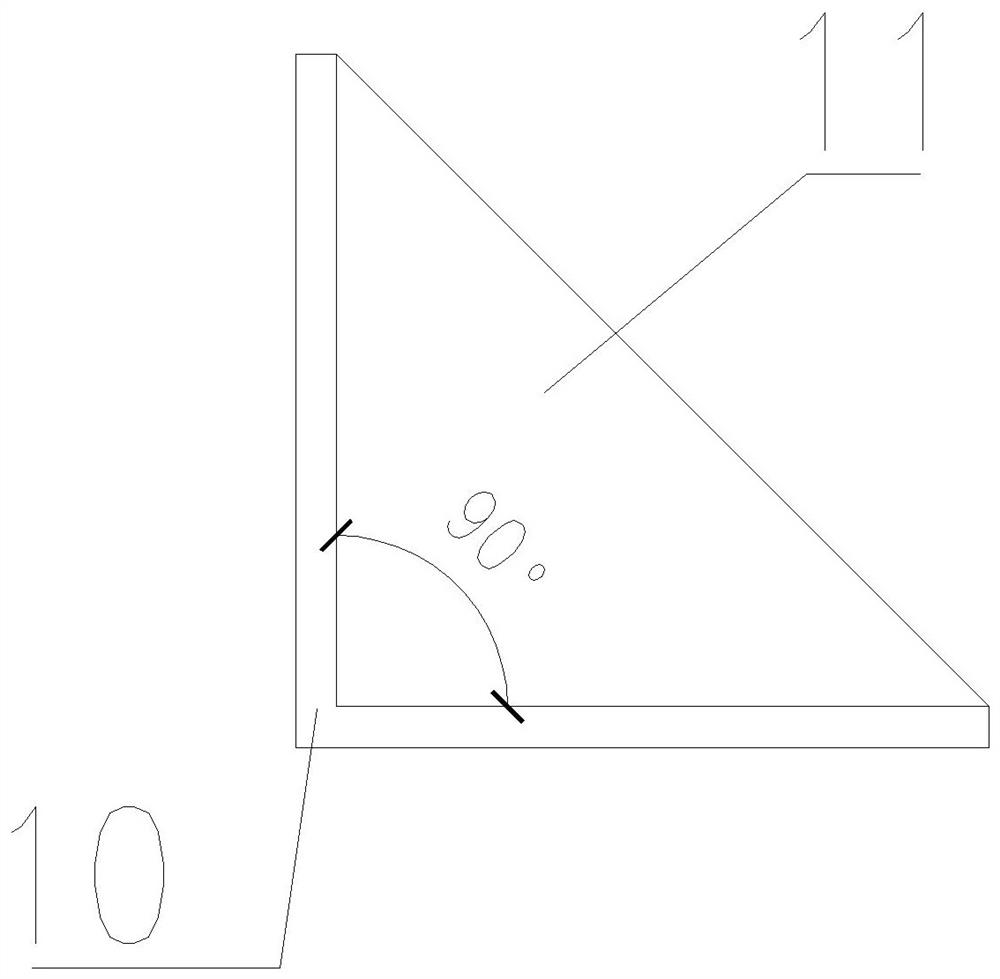

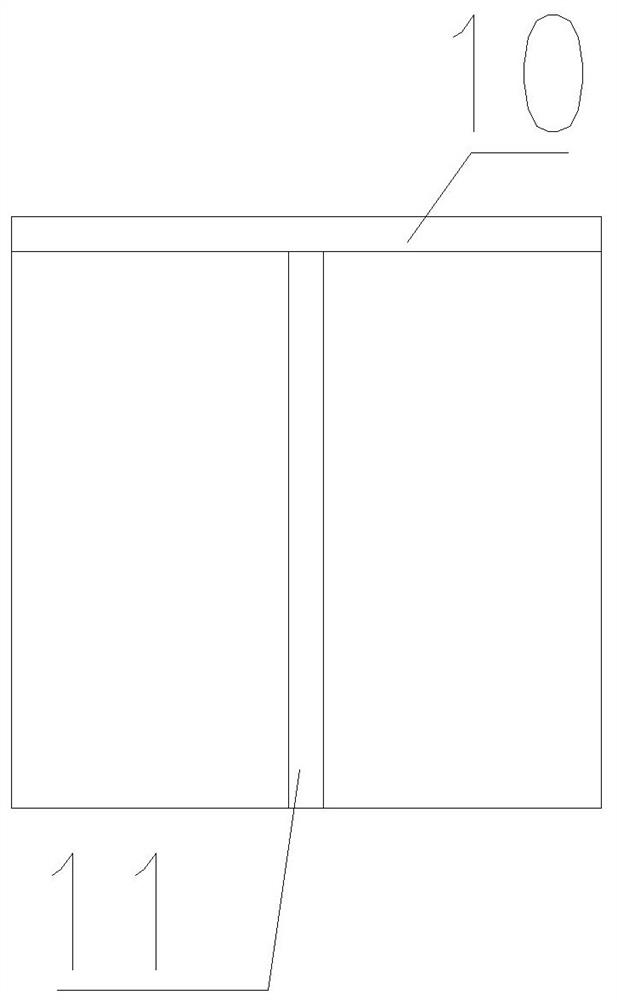

[0057] The device includes a lifting lug 1, a vertical jack 6, a lifting support 3, a concrete foundation 4 and a slide rail 5; the lifting support 3 is arranged on the surface of the concrete foundation 4, and behind it is a longitudinal slide rail 5; the steel frame body The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com