Wind generating set flange connecting bolt fracture positioning early warning method

A technology for wind turbines and connecting bolts, which is applied in wind turbines, monitoring of wind turbines, and wind power generation, and can solve problems such as high cost, high requirements for the installation environment, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

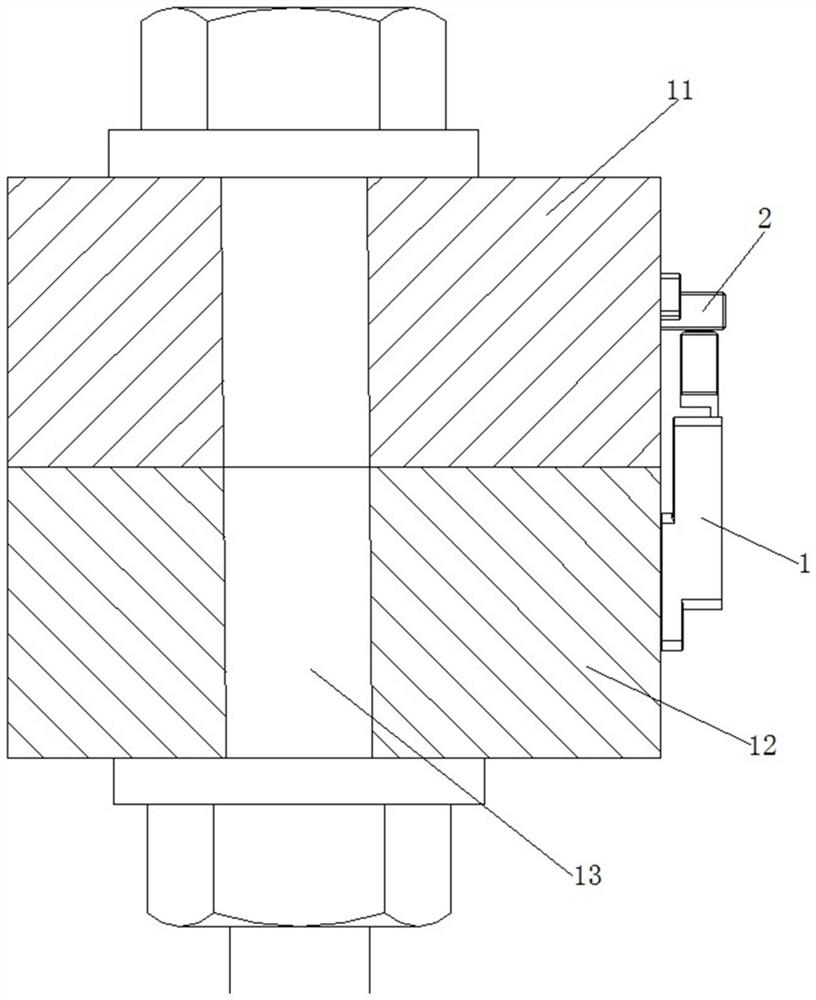

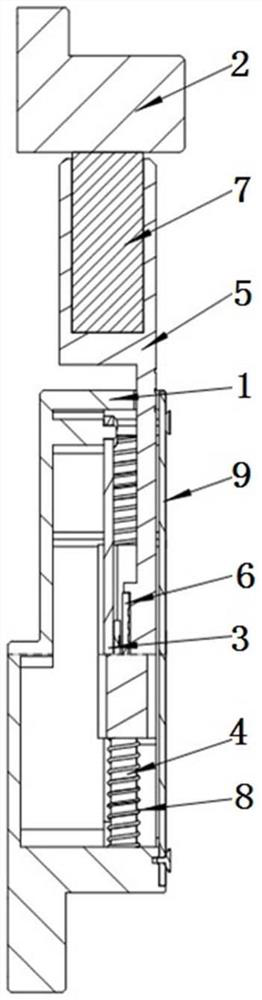

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

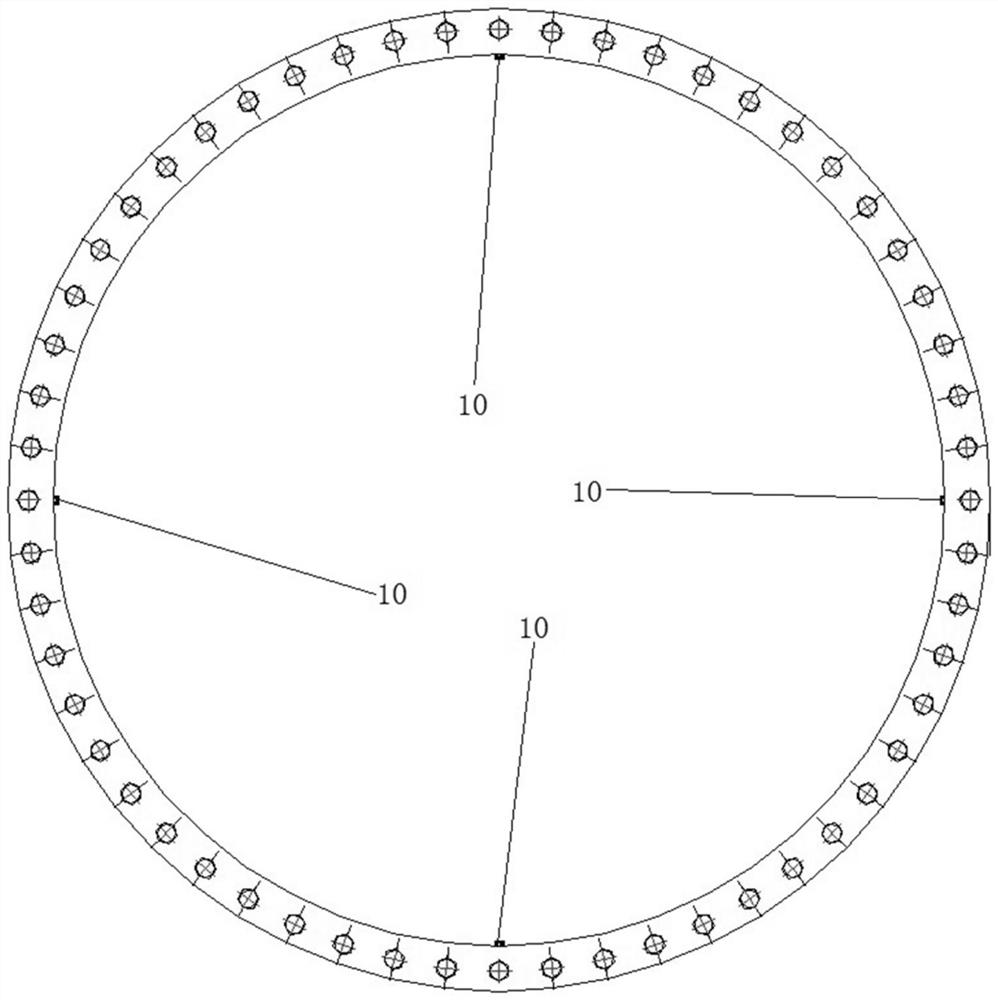

[0028] The invention provides a method for early warning of fracture location of flange connection bolts of a wind power generating set, referring to Figure 1 to Figure 4 , including the following steps:

[0029] (1) The wind speed is divided into bins, and the wind speed is divided into N wind speed intervals from low to high; the flange yaw position is equivalent to 0° to 360°, and the flange yaw position is divided into bins, The yaw position of the flange is divided into M yaw position intervals according to the angle; M×N storage bins are set, each storage bin corresponds to a wind speed segment composed of a wind speed interval and a yaw position interval, and each storage bin stores Up to n data;

[0030] In this embodiment, N is set to 13, and the wind speed between 0 and 0.5 (excluding 0.5) is a 0-meter wind speed cabin, and between 0.5 and 1.5 (excluding 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com