A Frame Structure Optimization Method Based on 3D Printing

A 3D printing and frame structure technology, applied in the field of 3D printing manufacturing, can solve problems such as difficult problems, and achieve the effects of good structural strength, shortened modeling time, and excellent structure and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

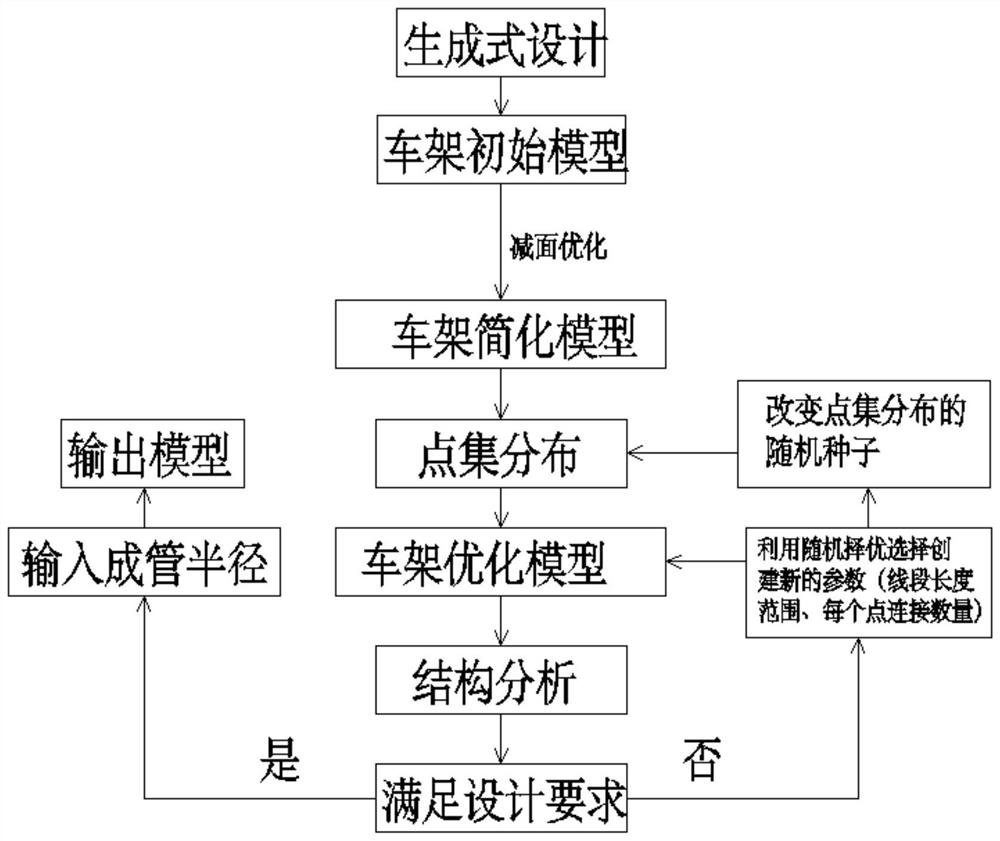

[0026] Example 1. A frame structure optimization method based on 3D printing, see figure 1 , follow the steps below:

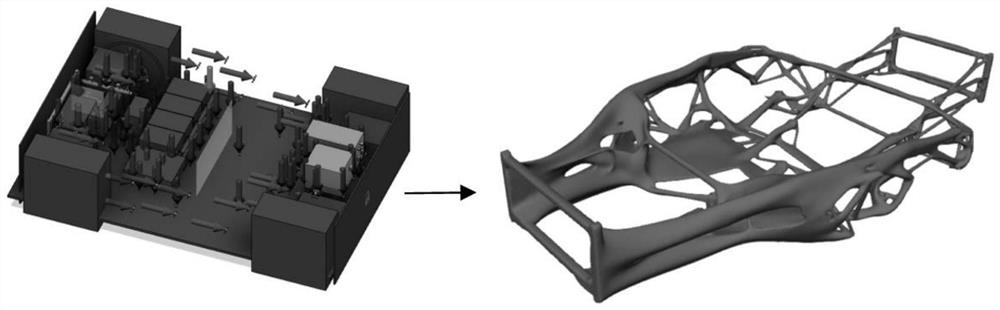

[0027] a. Input the force and material property information of the frame according to the design requirements, and use generative design to construct the initial model of the frame; see figure 2 ; Specifically, the initial model of the frame is constructed using the generative design software based on the progressive structure optimization method; through the generative design, the low-stress materials in the traditional frame structure are gradually removed, and the remaining structure finally evolves into the optimal frame The shape; the mechanical properties of the frame designed by this design method are more reasonable, and the material consumption is saved at the same time. However, since the frame structure designed by this design method is still relatively complex, it cannot be directly manufactured by 3D printing, so it is necessary to optimize the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com