Method for calculating equivalent stiffness and equivalent damping of fluid fulcrum tilting pad sliding bearing

A sliding bearing and equivalent stiffness technology, applied in the field of bearings, can solve problems such as data measurement difficulties and measurement errors, and achieve the effect of comprehensive calculation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings.

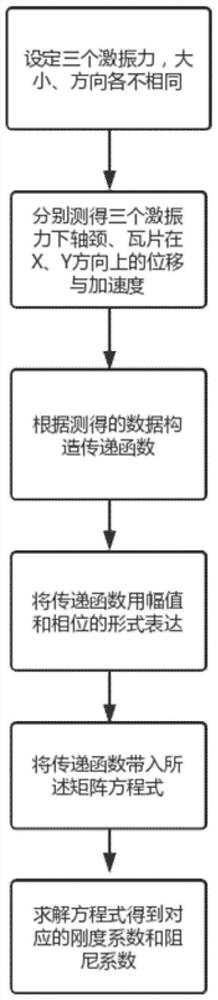

[0042] like image 3 As shown in the figure, the calculation method of the equivalent stiffness and equivalent damping of the fluid fulcrum tilting pad sliding bearing includes the following steps:

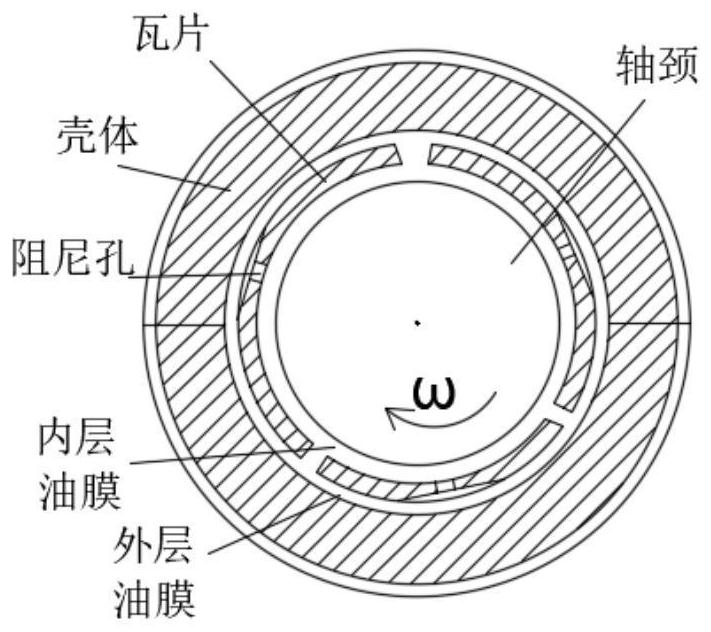

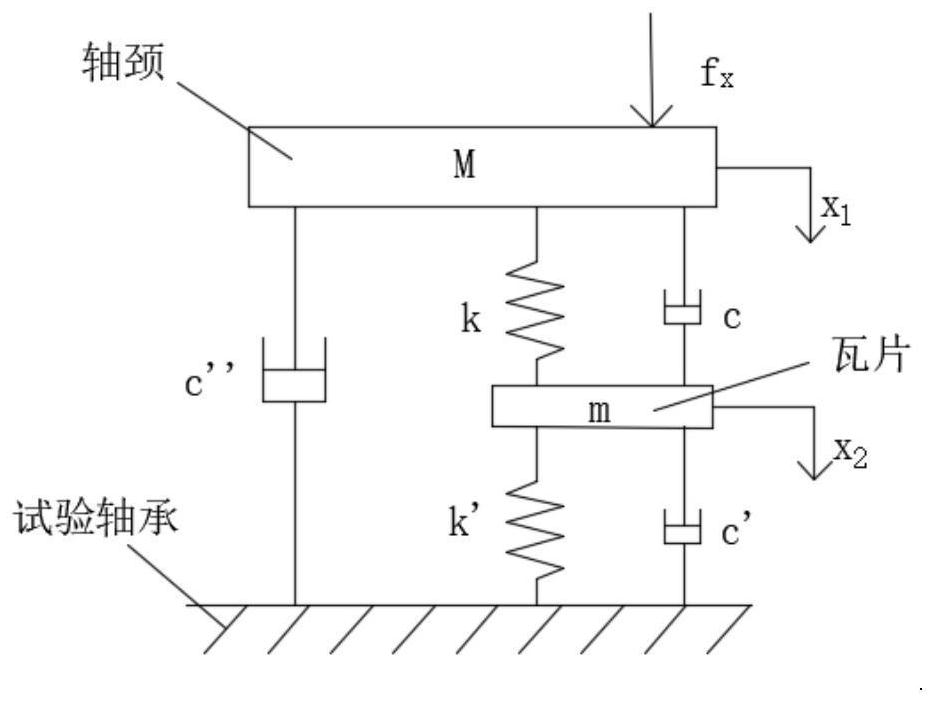

[0043] Step 1, such as figure 1 and 2 As shown, the exciting force of the journal is converted into forces in the x and y directions, the x and y directions are both arranged radially along the journal, and the x and y directions are perpendicular; based on the theory of elastohydrodynamic lubrication, the journal is established , the equivalent dynamic model of the inner oil film, the outer oil film and the tilting pad sliding bearing: the shell of the tilting pad sliding bearing is fixed, and the pad and the shell of the tilting pad sliding bearing are connected in parallel through the spring k' and the damping c' , the tile and the journal are connected in parallel thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com