Overturning type vacuum sintering furnace for producing luminescent material

A technology for vacuum sintering furnaces and luminescent materials, which is applied in furnaces, muffle furnaces, cooking furnaces, etc., and can solve problems such as large temperature differences, material temperature differences, and affecting the quality of material sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

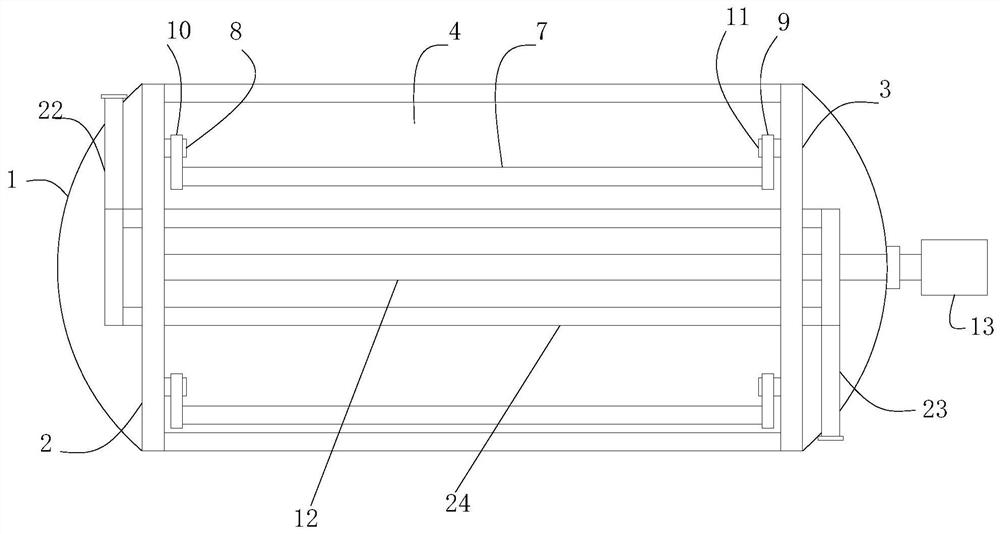

[0016] refer to Figure 1-Figure 3 , the present invention proposes an overturning vacuum sintering furnace for the production of luminescent materials, including a furnace body 1 and an overturning mechanism arranged in the furnace body 1; wherein:

[0017] The interior of the furnace body 1 is equipped with a first mounting plate 2 and a second mounting plate 3 arranged oppositely, and a sintering cavity 4 is formed between the first mounting plate 2 and the second mounting plate 3. The side of the furnace body 1 is provided with a sintering cavity 4 There is a connected opening and a furnace cover is installed at the opening position. Both the first mounting plate 2 and the second mounting plate 3 are made of thermal insulation materials to ensure the sintering temperature of the sintering cavity 4 .

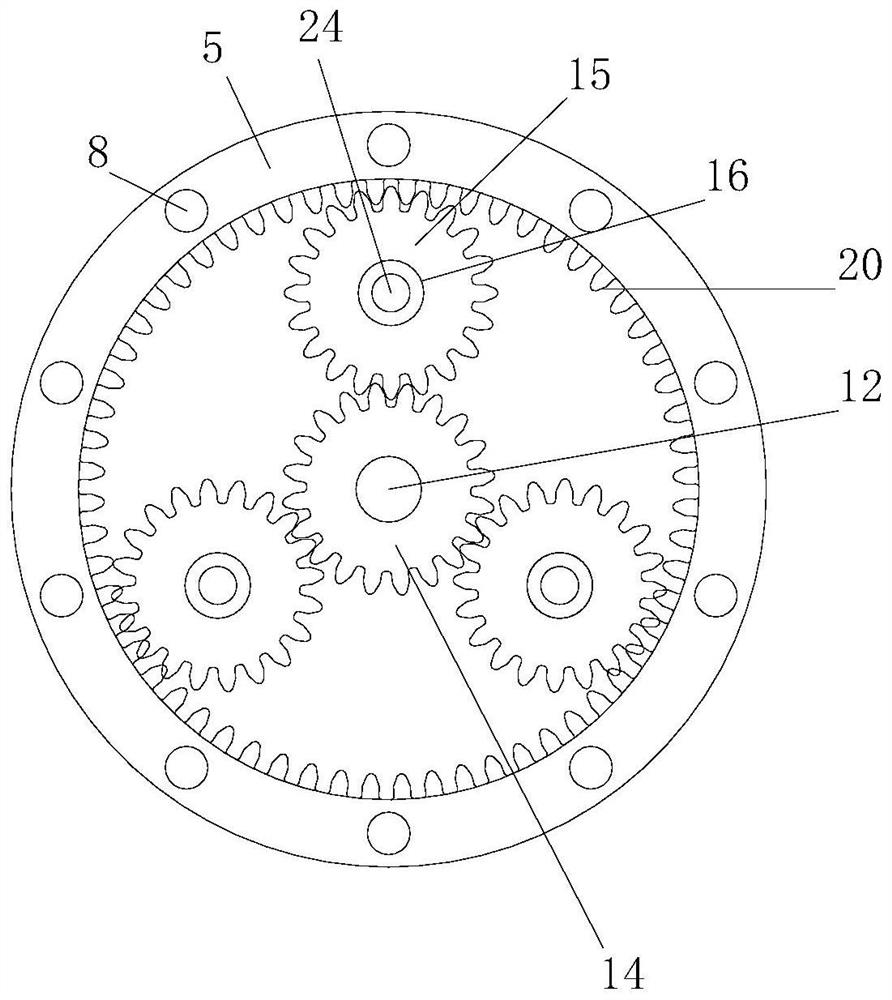

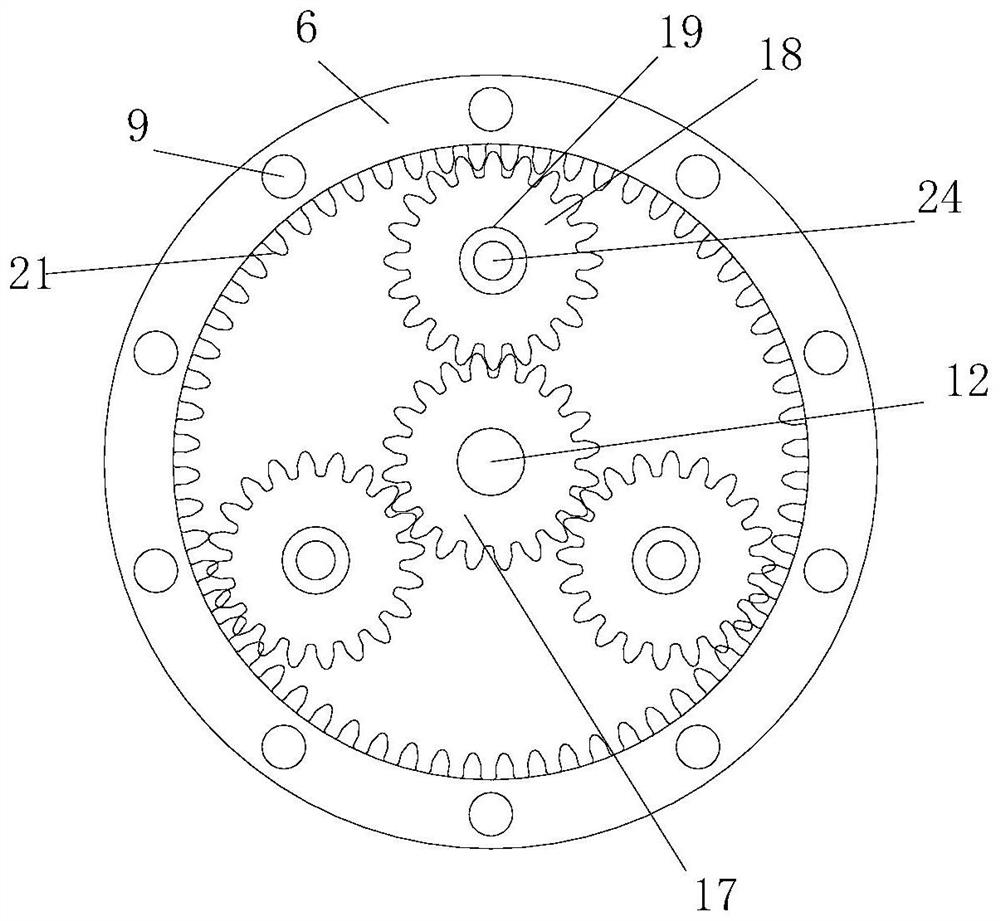

[0018] The turning mechanism includes a drive member, a first rotating ring 5, a second rotating ring and a plurality of sintering tanks 7 for placing sintering materials. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com