Driving mechanism, driving device and electronic equipment

A driving device and driving mechanism technology, applied in the field of driving devices, electronic equipment, and driving mechanisms, can solve the problems of slow focusing speed, inability to meet higher requirements on accuracy, and impact on imaging effects, and achieve high focusing accuracy and high precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

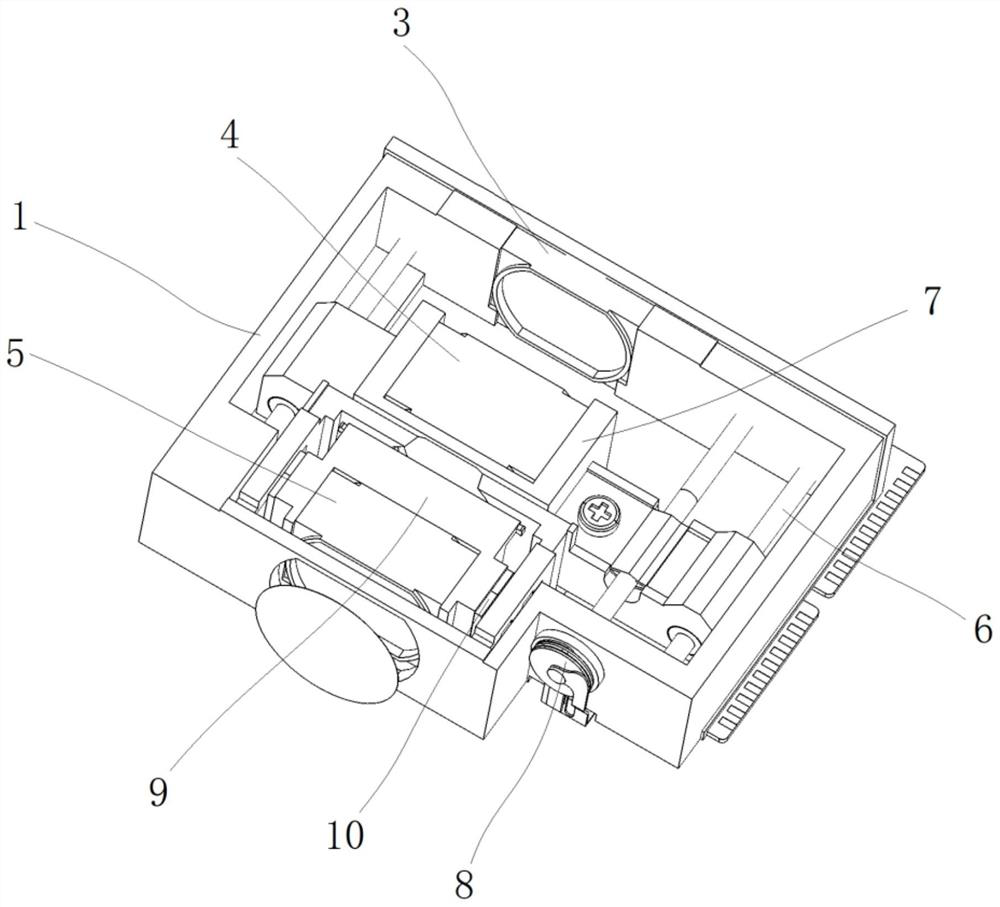

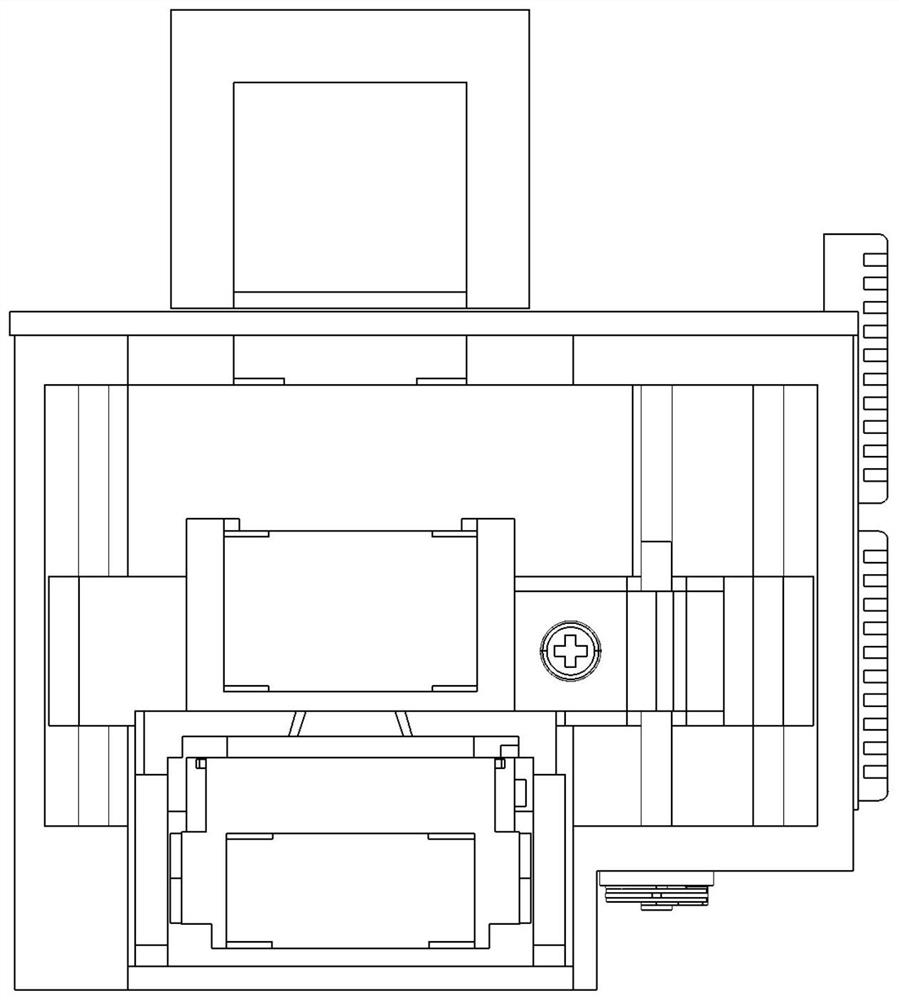

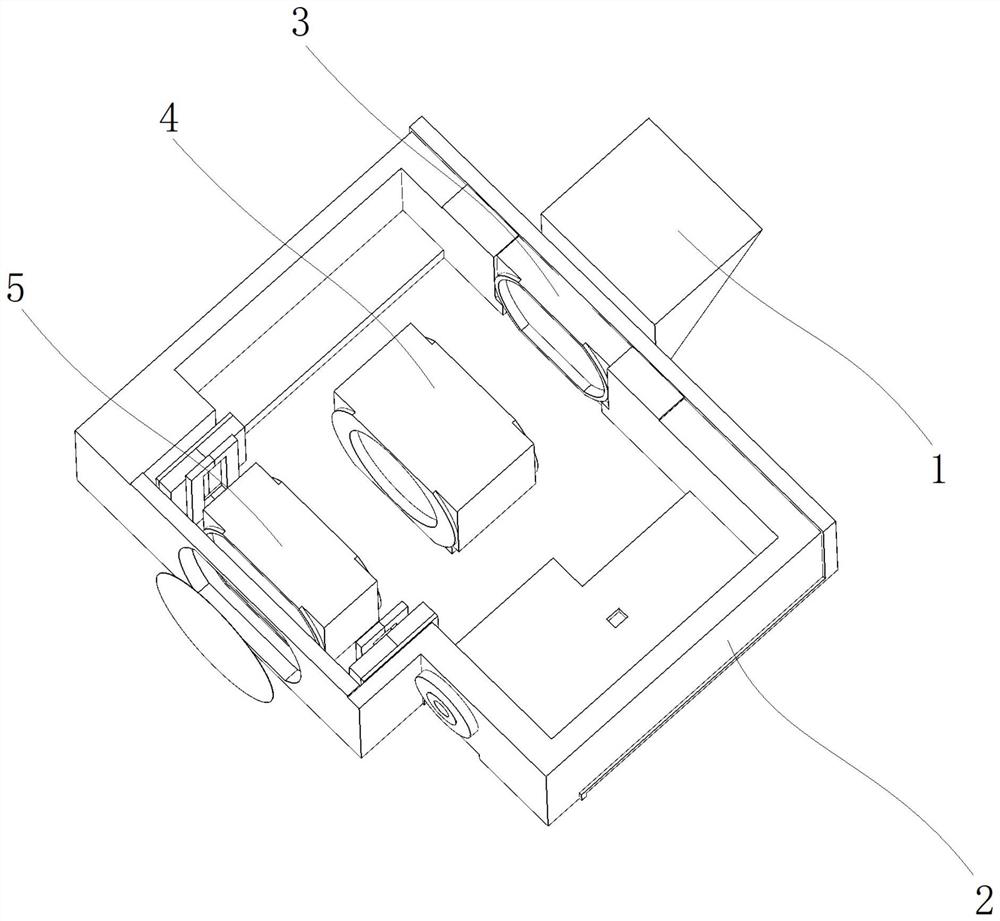

[0050] A driving mechanism, comprising a frame (1), a slide rail bracket (6) is provided inside the frame (1), a first carrier (7) is movably mounted on the slide rail bracket (6), and the first carrier The side of (7) is provided with a piezoelectric motor (8), and the piezoelectric motor (8) adopts GMR closed-loop control, and the output end of the piezoelectric motor (8) is connected and drives the first carrier (7) along the slide rail support (6 )move;

[0051] A second lens (4) is fixed on the front side of the first carrier (7);

[0052] The rear side of the first carrier (7) is provided with a continuous zoom motor (10) and a second carrier (9), the autofocus motor (10) adopts open-loop control or closed-loop control of Hall elements, and the autofocus motor ( 10) Connect and drive the second carrier (9), on which the third lens (5) is arranged.

[0053] The side of the frame (1) is provided with a mounting groove (101), the first lens (3) is fixedly arranged in the mo...

Embodiment 2

[0064] A driving device has the driving mechanism as described in Embodiment 1. In this embodiment, other structures of the driving device are the same as those of the prior art, so no detailed description is given here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com