Technical supervision standardization method and system and technical supervision plan making method

A technical supervision and standard technology, applied in the field of information management, can solve problems such as the need to improve the supervision level, low supervision efficiency, missing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

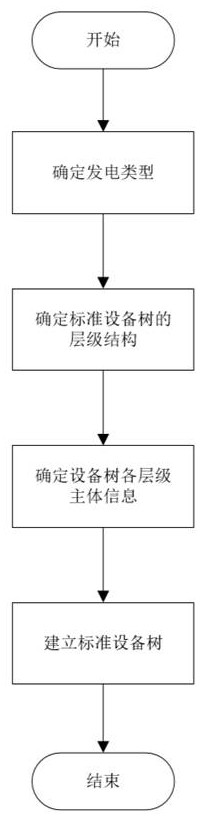

[0042] Embodiment 1. A method for standardizing technical supervision centered on equipment, comprising the following steps: establishing a standard equipment tree according to the associations between units corresponding to different power generation types, various systems of the units, and types of equipment included in the system;

[0043] A standard supervision library is established, the standard supervision library includes the name of each supervision item and the equipment type associated with each supervision item name, and also includes the supervision item information corresponding to each supervision item name and the test name associated with the supervision item, and the standard supervision library is associated with the supervision item name. The standard device tree is associated by device type;

[0044] Establish a standard test library, the standard test library includes a test name library and a test item library, and the test name library includes each test...

Embodiment 2

[0065] Embodiment 2. Corresponding to Embodiment 1, this embodiment provides a device-centered technical supervision standardization system. The system is established according to the device-centered technical supervision standardization method provided in Embodiment 1, such as: Figure 13 As shown, the system includes: standard equipment tree, standard supervision library and standard test library;

[0066] The standard equipment tree is used to represent the association relationship between the units corresponding to different power generation types, various systems of the units, and the types of equipment included in the systems;

[0067] The standard supervision library includes the name of each supervision item and the equipment type associated with each supervision item name, and also includes the supervision item information corresponding to each supervision item name and the test name associated with the supervision item, and the standard supervision library and the sta...

Embodiment 4

[0094] In the fourth embodiment, on the basis of the third paragraph of the embodiment and the standardization of the supervision work, its application can be further expanded. This embodiment provides a method for formulating a technical supervision plan centered on equipment. Based on the instantiated equipment tree of the power plant, with the equipment KKS code as a link, the equipment-related static ledger information, supervision indicators, operating parameters, daily work records, Integrate multi-dimensional information such as maintenance supervision records to build an equipment center, such as Figure 12 shown. Realize the further expansion of the standardization of supervision work.

[0095] like Figure 12 As shown, the subsystems included in the #1 unit include the steam turbine system of the #1 unit, the electrical system of the #1 unit, and the boiler system of the #1 unit. Among them, the boiler system of the #1 unit includes the #1 unit boiler and the #1 un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com