Quantitatively-rotating winding machine base for winding high-voltage coil of dry-type transformer

A technology of dry-type transformers and high-voltage coils, applied in coil manufacturing, cabinet/cabinet/drawer components, electrical components, etc., can solve potential safety hazards, troubles and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

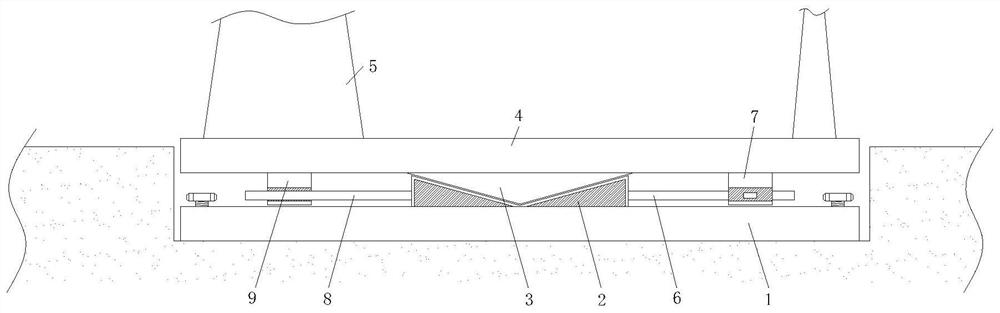

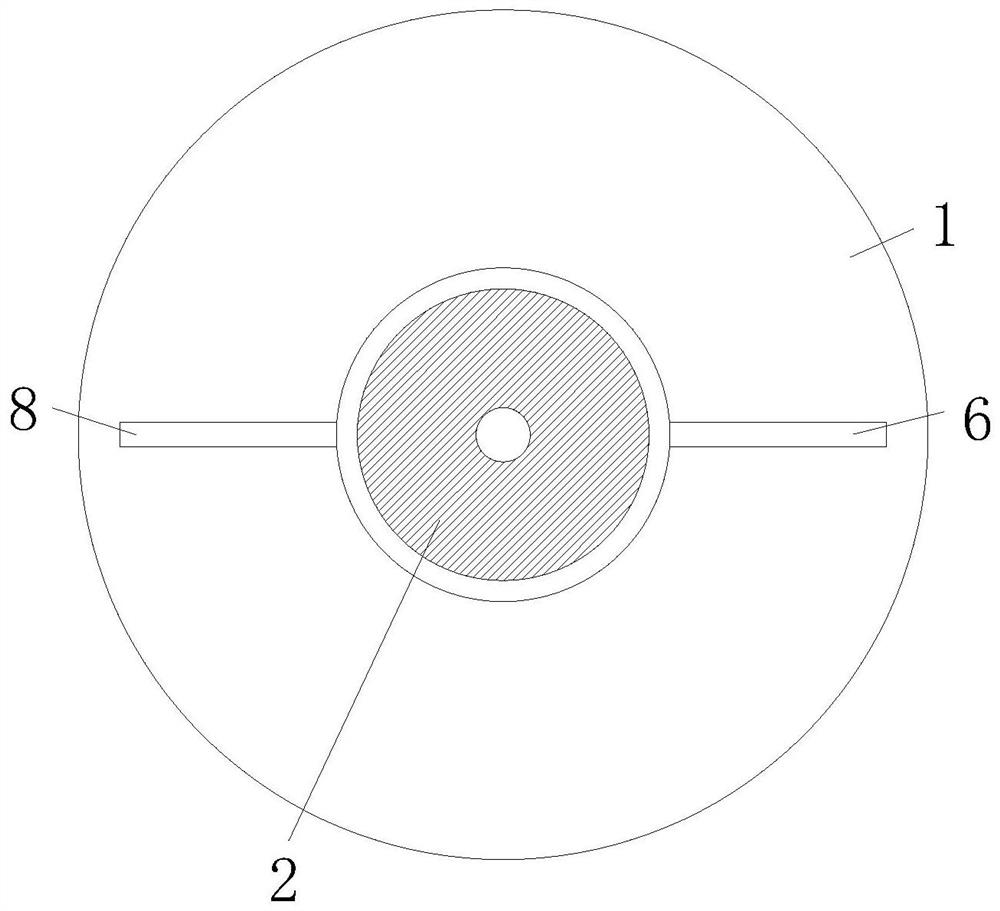

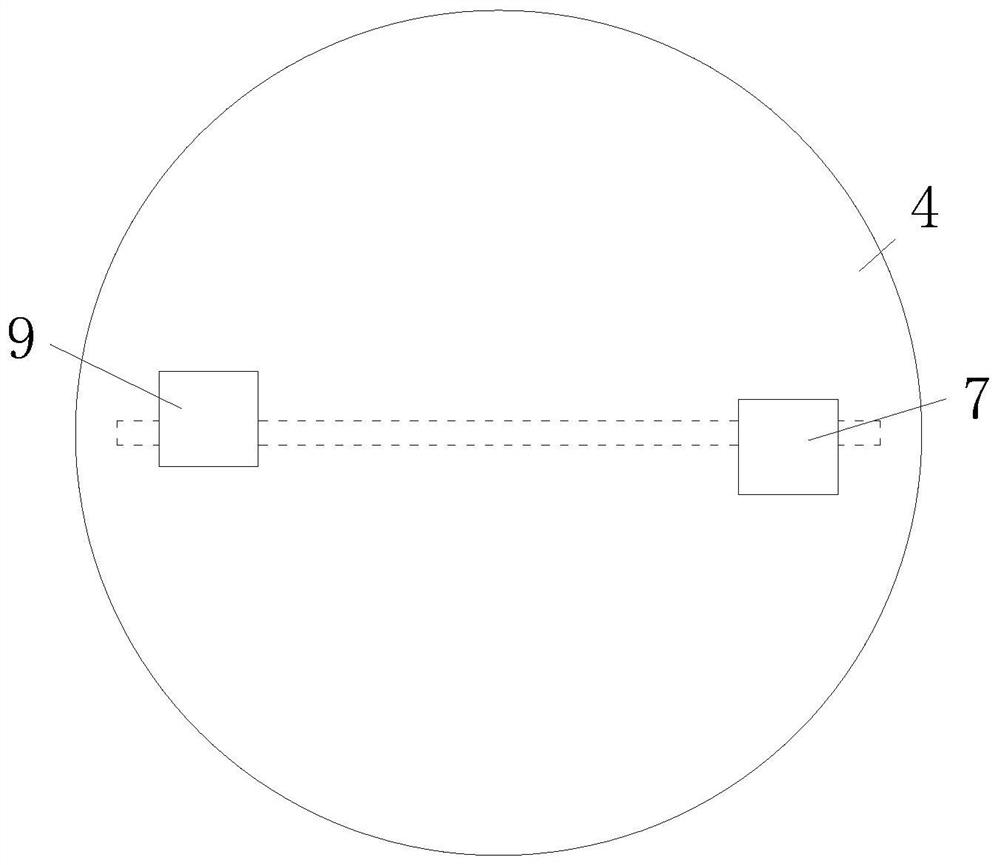

[0030] Such as Figure 1-9As shown, the present invention provides a technical solution: a winding machine base for quantitatively rotating dry-type transformer high-voltage coil winding, including a fixed circular plate 1, which is fixed in a groove opened on the ground, The central position of the fixed circular plate 1 is vertically connected with a conical rotary positioning seat 2, the inner wall of the conical rotary positioning seat 2 is socketed with the outer surface of the conical positioning rotary block 3, and the top of the conical positioning rotary block 3 is in contact with the rotating circle. The center position of the bottom of the plate 4 is fixedly connected, the top of the rotating circular plate 4 is fixedly connected with the bottom of the winding machine body 5, and the conical rotating positioning seat 2 fixedly connected to the top of the fixed circular plate 1 and the bottom of the rotating circular plate 4 are fixed. Connected conical positioning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com