Antenna structure for improving cross polarization performance of dual-polarized microstrip antenna

A microstrip antenna, cross-polarization technology, applied in the direction of the antenna grounding switch structure connection, antenna coupling, radiating element structure, etc., can solve the problems of mutual crosstalk isolation, low antenna polarization purity, and insufficient Gains, ease of debugging and real-time tuning, effects to improve cross-polar performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

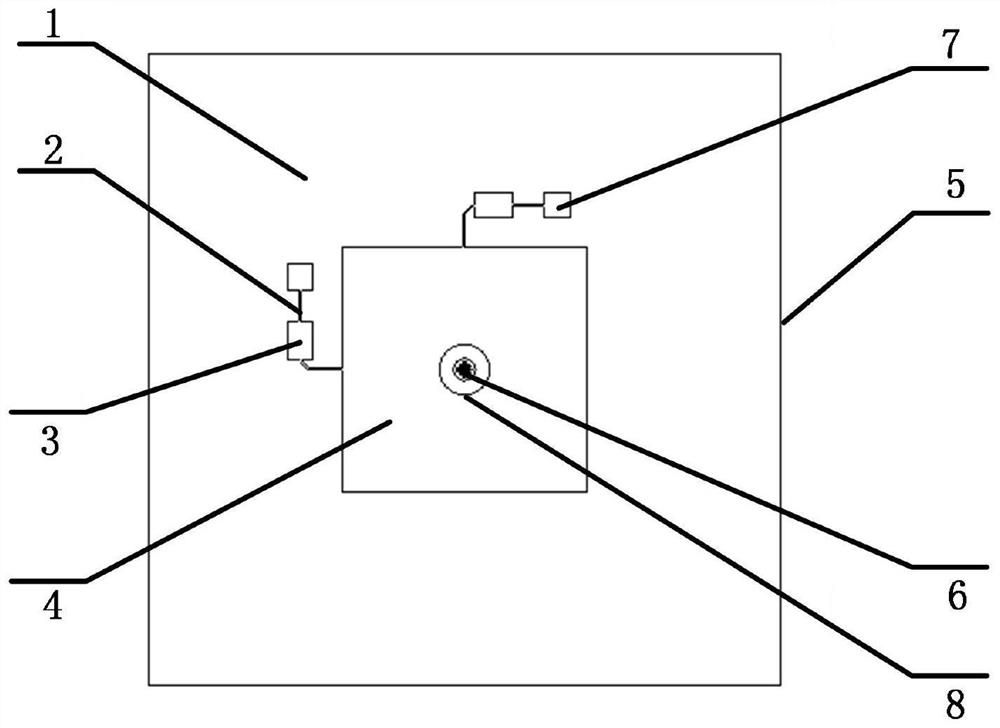

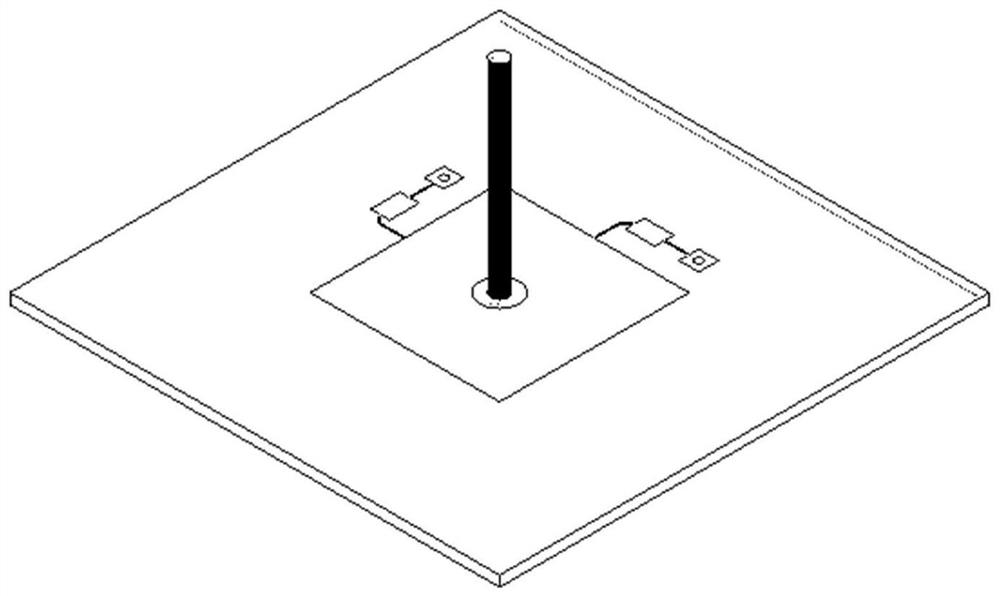

[0024] see Figure 1~5 , the present invention provides a technical solution: an antenna structure for improving the cross-polarization performance of a dual-polarized microstrip antenna, including a microwave dielectric substrate 1, a microstrip feeder 2, a distribution branch 3, a square metal patch 4, and a metal floor 5. The metal cylinder 6 and the feeding probe 7, the microstrip feeder 2, the deployment branch 3, and the square metal patch 4 are arranged on the upper surface of the microwave dielectric substrate 1, and the metal floor 5 is arranged on the microwave dielectric substrate 1 The lower surface of the distribution branch 3 and the feeding probe 7 are provided with two groups, the distribution branch 3 is connected to the square metal patch 4, and the feeding probe 7 is connected to the distribution through the microstrip feeder 2 Branches 3 are connected.

[0025] The center of the square metal patch 4 is provided with a through hole 8, the through hole 8 is ...

Embodiment 2

[0032] The difference from the first embodiment is that the metal cylinder 6 is fixedly installed on the metal floor 5 through lock nuts.

Embodiment 3

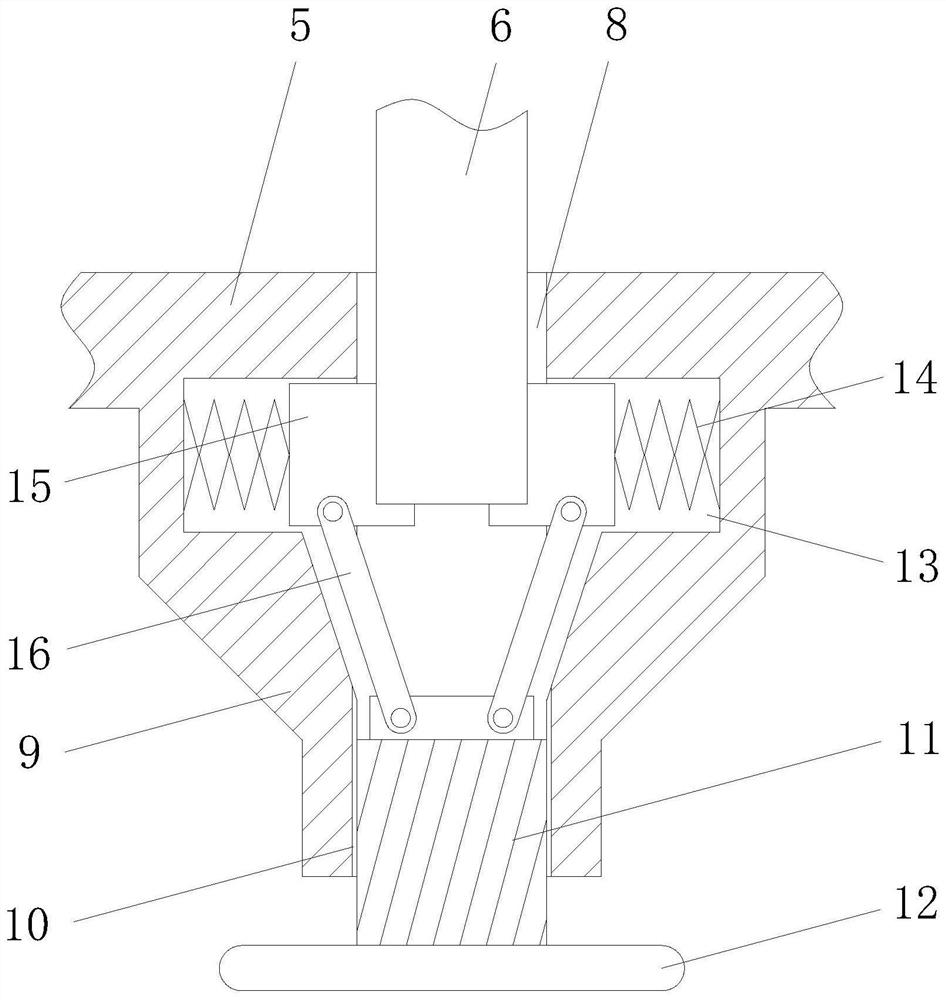

[0034] The difference from Embodiment 1 is that the metal cylinder 6 is fixed on the metal floor 5 through the installation mechanism, and the installation mechanism includes a fixing cylinder 9, which is arranged at the bottom end of the metal floor 5, and the fixing cylinder 9 The bottom end is provided with a threaded hole 10, a screw 11 is installed in the threaded hole 10, a knob 12 is installed at the bottom of the screw 11, a rotating block is connected to the top, and several connecting rods 16 are installed on the top of the rotating block. The inside of the fixed cylinder 9 is provided with a plurality of chute 13, a plurality of chute 13 is evenly distributed around the central axis of the fixed cylinder 9, a locking block 15 is slidably installed in the chute 13, and the locking block 15 is far away from the fixed One end of the central axis of the barrel 9 is connected to the inner wall of the chute 13 through a spring 14, and the top of the connecting rod 16 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com